Portable tile chamfering cutting machine

A cutting machine, a portable technology, applied in the direction of stone processing tools, manufacturing tools, stone processing equipment, etc., can solve the problems that the quality of tile chamfering cannot be effectively controlled, increase the decoration cost of the decoration unit, and delay the decoration time, etc., to eliminate The effect of chamfering and bursting corner defects, reducing processing costs and saving decoration time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

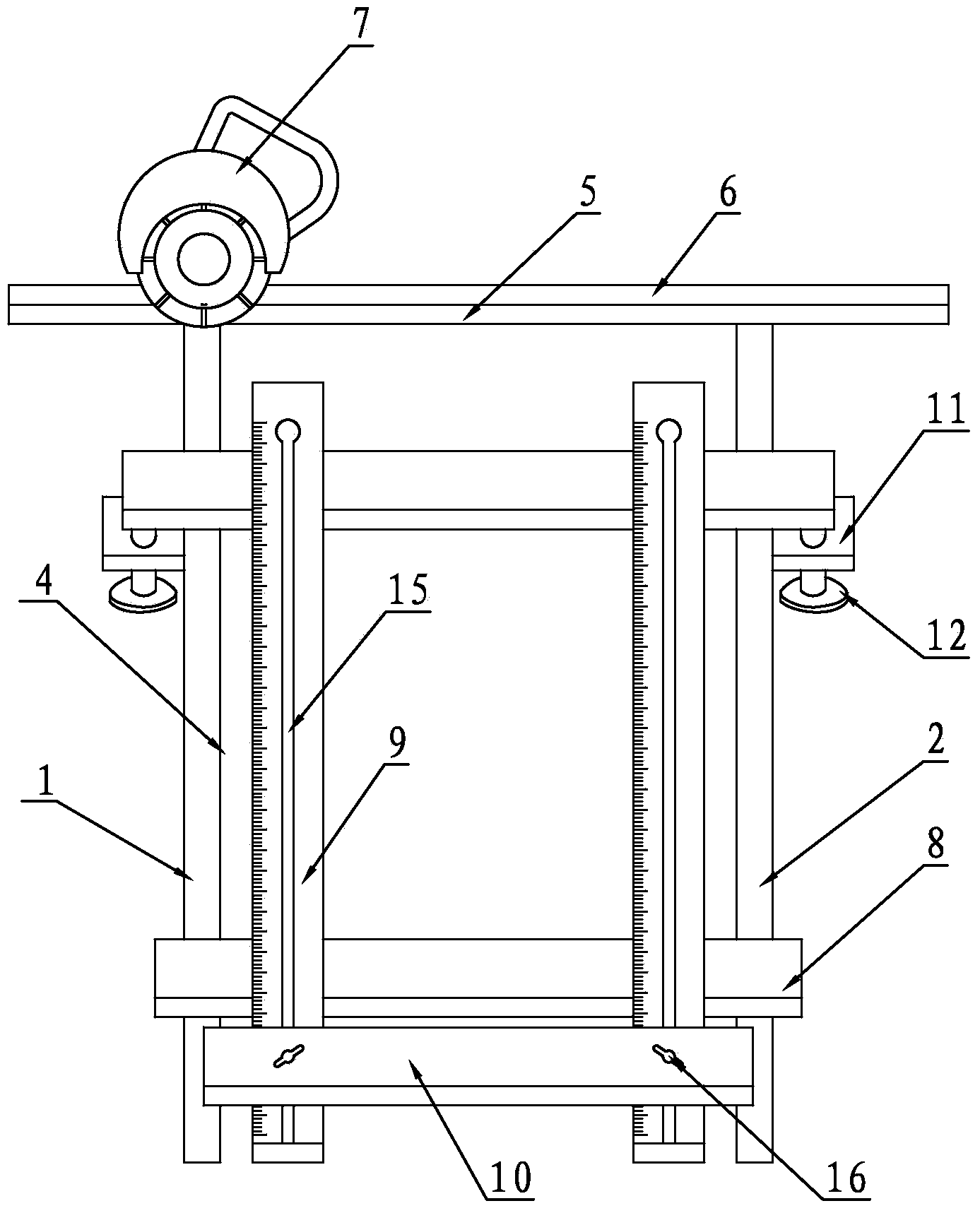

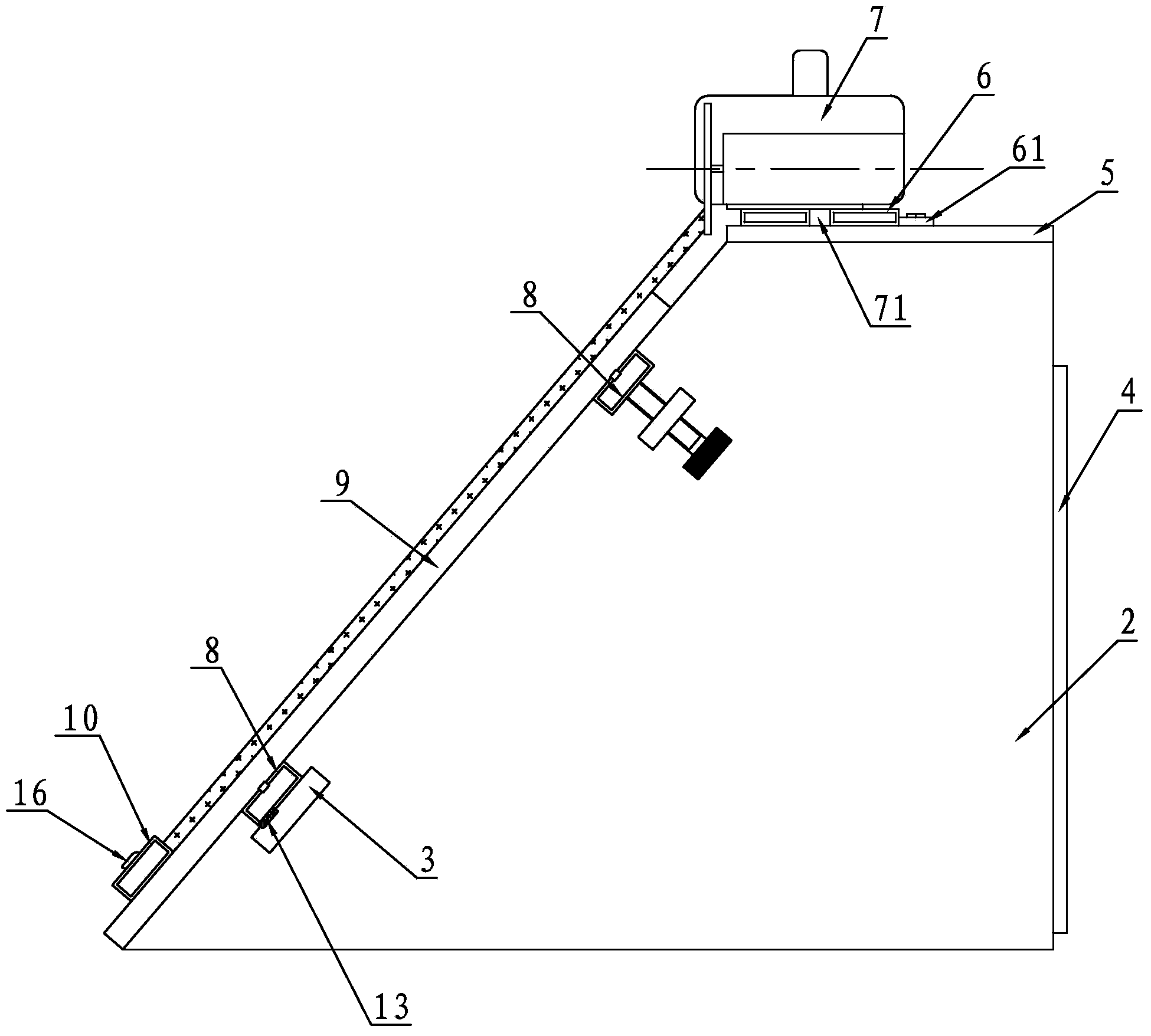

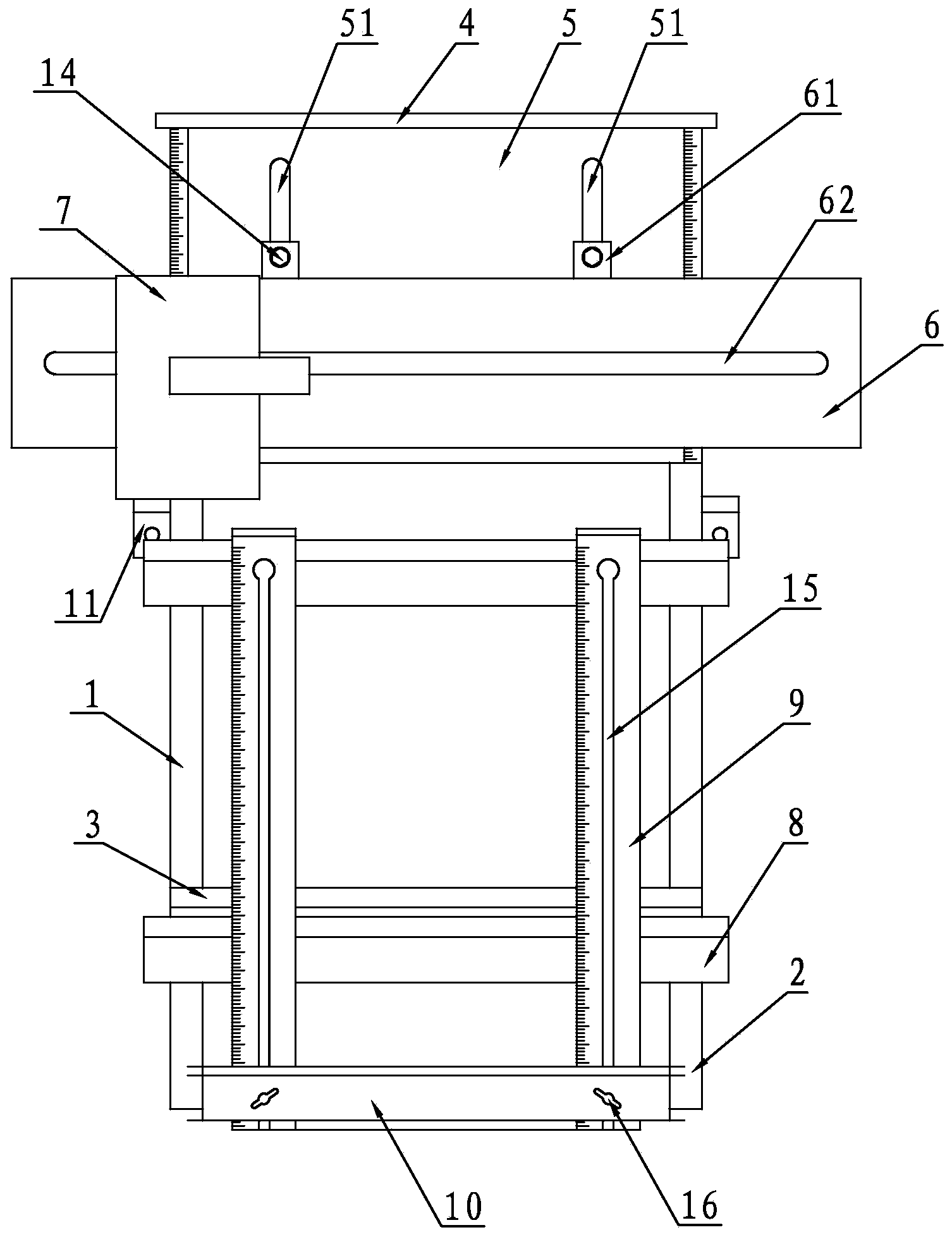

[0014] A portable tile chamfering cutting machine, such as Figure 1 ~ Figure 3 As shown, it includes left side board 1, right side board 2, front horizontal board 3, back board 4, working table 5, cutting machine sliding guide rail 6, portable cutting machine 7, transverse connecting rod 8, tile support rod 9, horizontal Limiting rod 10, ear seat 11, angle adjustment screw 12 and hinge 13, the left side plate 1 and the right side plate 2 have the same shape and size, the side shape is trapezoidal, the front end face is an inclined plane, and the angle between the inclined plane and the ground is 45° , the front transverse board 3 is fixedly connected to the front slopes of the left side board 1 and the right side board 2, the back board 4 is connected between the rear inner side of the left side board 1 and the right side board 2, and the workbench 5 is fixedly installed horizontally On the top surface of the left side plate 1 and the right side plate 2, there are two guide r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com