Assembly and inspection method of dual-curvature skin type part

An inspection method and hyperbolic technology, applied in aircraft assembly, aircraft parts, ground installations, etc., can solve problems such as affecting aerodynamic shape and stealth, difficulty in shortening assembly cycle, and large difference in theoretical position of aircraft.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] A method for assembling and inspecting hyperbolic skin parts, characterized in that it comprises the following steps:

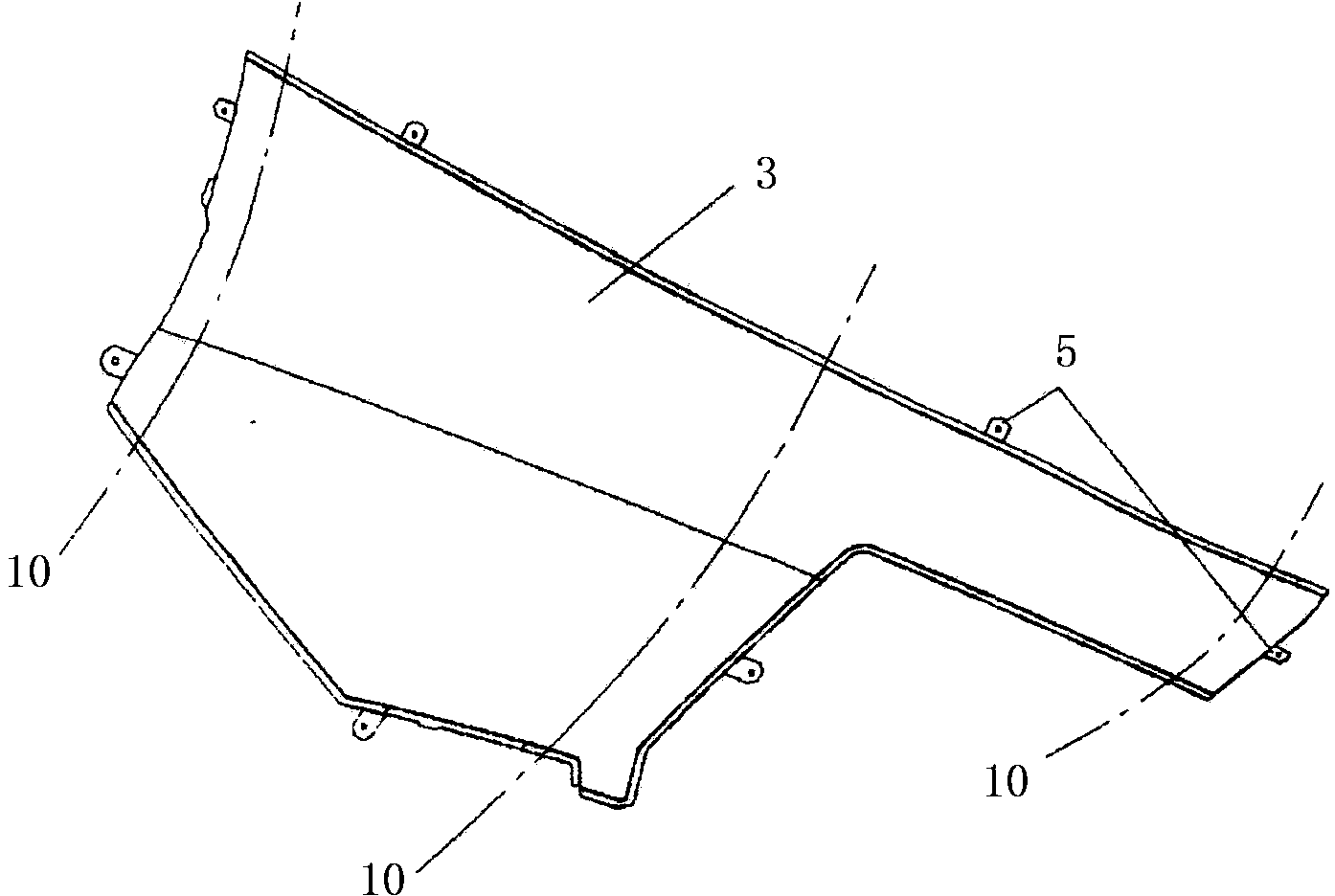

[0021] 1) if figure 1 As shown, according to the theoretical shape of the hyperbolic skin and the position of the main load-bearing structure, several process lugs 5 are added on the outer edge of the skin during the design process of the skin, and according to the aerodynamic shape of the hyperbolic skin The position of the process lug 5 is determined according to the bearing characteristics, and the material and angle of the process lug 5 are consistent with the double curvature skin;

[0022] 2) After the actual parts of the hyperbolic skin 3 with the craft lug 5 are produced, through-holes are drilled in the craft lug 5, and the size of the through-hole and the distance from the edge are determined by simulating the force to be borne;

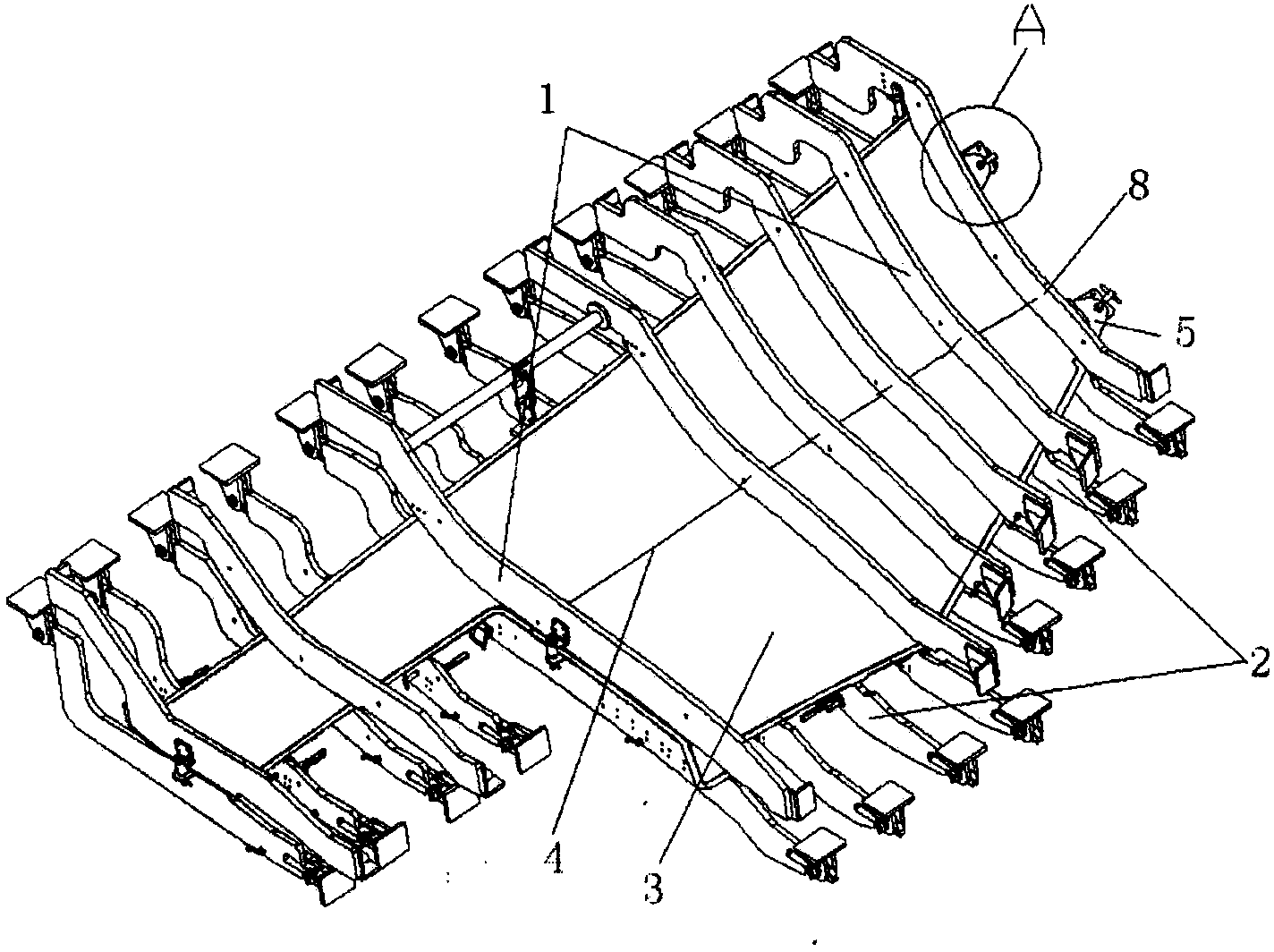

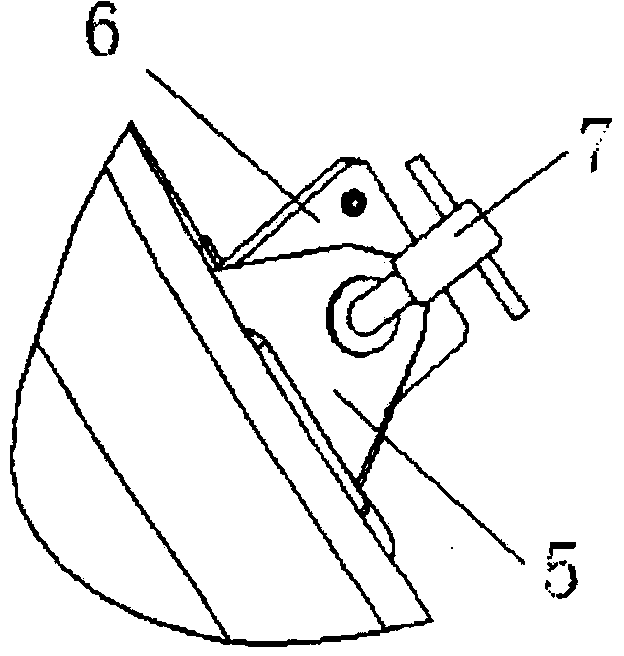

[0023] 3) On the outer edge pallet group 1 and the inner edge pallet group 2 of the double-curvature skin toolin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com