Volume fixing tank for cold drinks and volume fixing method

A constant volume, cold drink technology, applied in the direction of containers, large containers, measuring devices, etc., can solve the problems of flow meter fragility, inconvenient maintenance and inconvenient use, etc., to achieve convenient automatic production, convenient inspection and maintenance, and simple principle Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

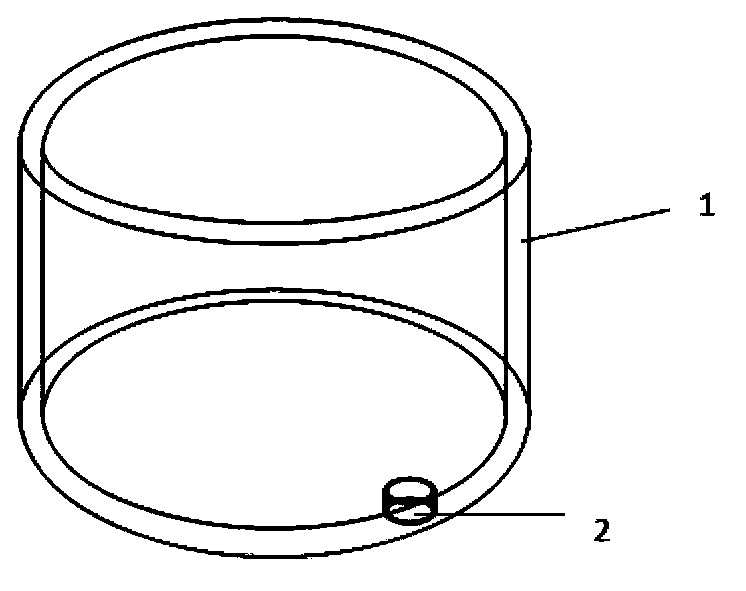

[0030] The constant volume tank for cold drinking of the present invention includes a tank body 1 and also includes: a pressure gauge 2 arranged on it. When the frozen beverage material liquid is constant volume, the material liquid enters the tank body 1, and the quality of the material liquid is read by the weight scale converted based on the bottom area of the tank body 1 by the pressure gauge 2. The formula based on the conversion of the bottom area of the tank 1 is m=Ps / g, where m is the weight of the liquid, P is the pressure, s is the cross-sectional area of the tank 1, and g is the acceleration of gravity. The pressure gauge 2 can be connected with an automatic batching system to facilitate automatic production.

[0031] Finally, it should be noted that the above embodiments are only used to illustrate the technical sol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com