Tempered glass online automatic detection device

A tempered glass, automatic detection technology, applied in lighting and heating equipment, conveyor control devices, conveyor objects, etc., can solve the problems of time-consuming and labor-intensive, difficult to control the pneumatic balance of the test table lifting, and inconvenient online detection. , to improve labor efficiency, solve the problem of lifting and pneumatic balance, and shorten the production time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

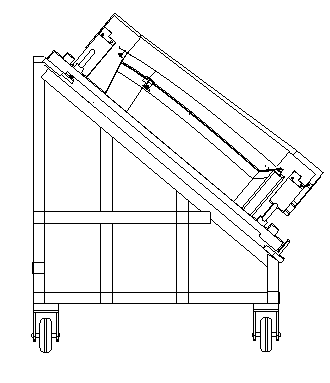

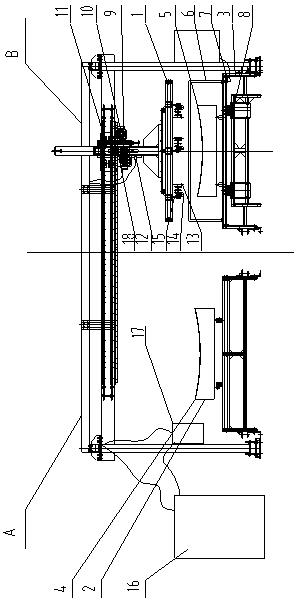

[0009] An on-line automatic inspection device for tempered glass, comprising a debugging part A and a detection part B, the detection part B includes a liftable online detection platform 1 and an automobile tempered glass production line 3, and a driving motor 9, Motor 10, balance cylinder 11, first photoelectric sensor switch 18, second photoelectric sensor switch 12 and spring buffer device 15, wear-resistant briquetting block 14 and retractable pneumatic detection head 13 are arranged under described online detection platform 1, The automobile tempered glass production line 3 is provided with a tempered glass mold trolley 6, the tempered glass 5 to be detected is placed on the tempered glass mold trolley 6, and a third photoelectric sensor switch is arranged below the tempered glass mold trolley 6 7. The third photoelectric sensor switch 7 blocks and positions the toughened glass mold trolley 6 by controlling the blocking cylinder 8 below it; the debugging part A is provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com