Active free radical starting agent and use thereof

A free radical and initiator technology, applied in the field of active free radical initiators, can solve problems such as low impact strength and glass transition temperature, inability to enter the automotive headlight market, water absorption limitation, etc., to achieve reduced gelling effect, glass Increased transition temperature and pyrolysis temperature, good quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

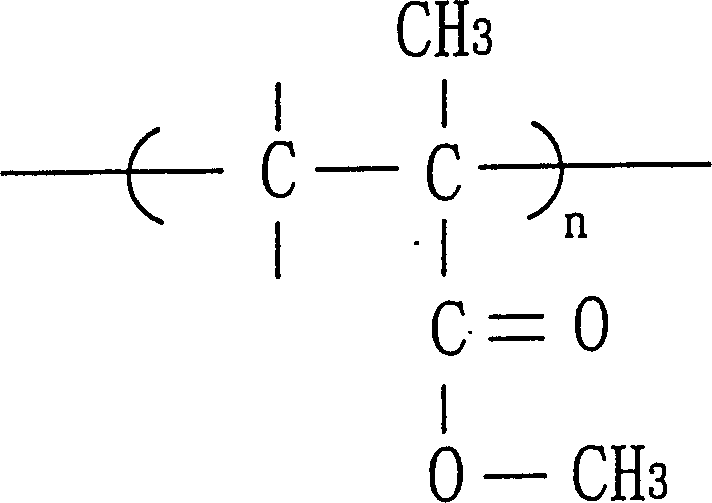

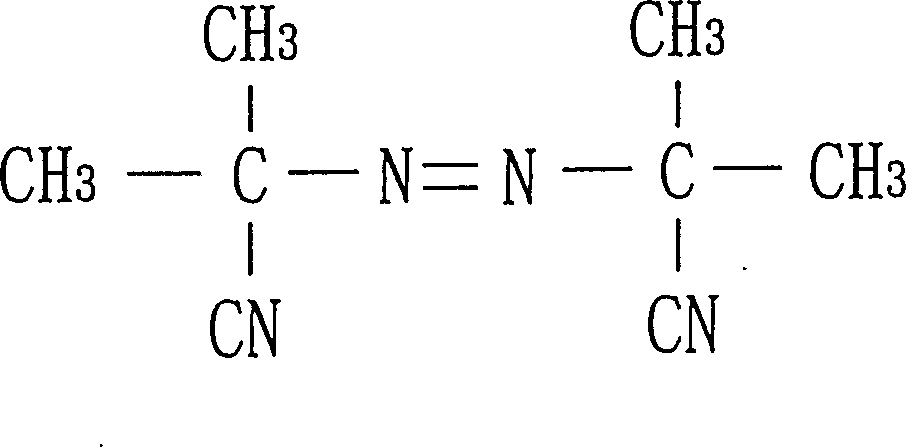

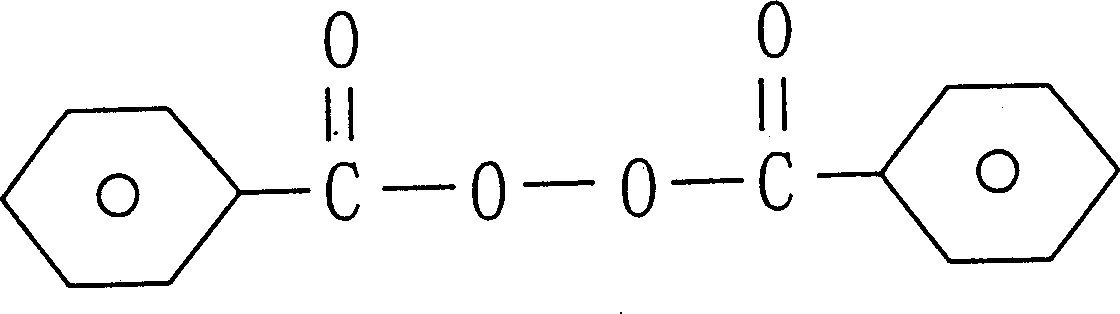

[0037] (embodiment one)-polymerization of methyl methacrylate

[0038] Take about 16 grams of methyl methacrylate monomer, about 20 grams of ε-caprolactam, and about 1.8 grams of n-dodecyl mercaptan, put them in a 2-liter reactor, and pre-polymerize at about 90 ° C for about 90 minutes. Then, pour the pre-polymer into two pieces of strengthened glass, put it in a constant temperature water tank at about 60°C until it hardens, and then you can get a transparent acrylic sheet. During the experiment, no gelation effect occurred, and no air bubbles were embedded in the acrylic plate.

[0039] Utilize thermal differential scanning card meter (DSC) and thermogravimetric analyzer (TGA) to analyze the above-mentioned polymethyl methacrylate that makes, the result is as follows Figure 8 and Figure 9 shown. Please refer to Figure 8 , where A is the heat flow curve of the polymer obtained using the initiator system of the present invention, and B is the heat flow curve of the pol...

Embodiment 2

[0040] (embodiment two)-block copolymerization of methyl methacrylate and styrene

[0041] In addition, in the present invention, after the polymer obtained by the method of Example 1 is purified, the second monomer can be continuously added into the reaction to obtain a functional block copolymer. first. Take about 15 g of the polymethyl methacrylate prepared in Example 1, dissolve it in about 50 g of toluene, add about 10 g of styrene (Styrene) monomer, react at about 90 ° C for about 6 hours, and then purify. Functional block copolymers can be obtained. The infrared spectrogram of polymethyl methacrylate and polystyrene (Polystyrene; PS) functional block copolymer obtained by the above method is as follows Figure 10 shown.

Embodiment 3

[0042] (embodiment three)-polymerization of styrene

[0043] Take about 200 grams of styrene (Styrene) monomer, about 2-5 grams of 2-pyrrolidone, and about 0.8 grams of n-dodecyl mercaptan, put them in a reactor, and carry out polymerization reaction at about 90 ° C for about 5 Hour. Then, after further purification, PS with a special functional group at the end can be obtained. No gelation occurred during this experiment.

[0044] From the above, it can be seen that the application of the living free radical initiator of the present invention in the polymerization of ethylene can effectively reduce or control the acceleration effect caused by the reaction heat, and avoid the disadvantages of the known gelation effect. Moreover, although the initiation reaction rate of the present invention is lower than that of the known ones, heating can be continued during the reaction process, thus shortening the polymerization time as a whole. In addition, if it is used for polymethyl ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| cracking temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com