Engine forced flameout device

An engine and control block technology, applied in the direction of engine control, machine/engine, mechanical equipment, etc., can solve the problems of complicated operation process and low safety factor of diesel engine, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] In order to clearly illustrate the technical features of the solution, the solution will be described below through a specific implementation manner.

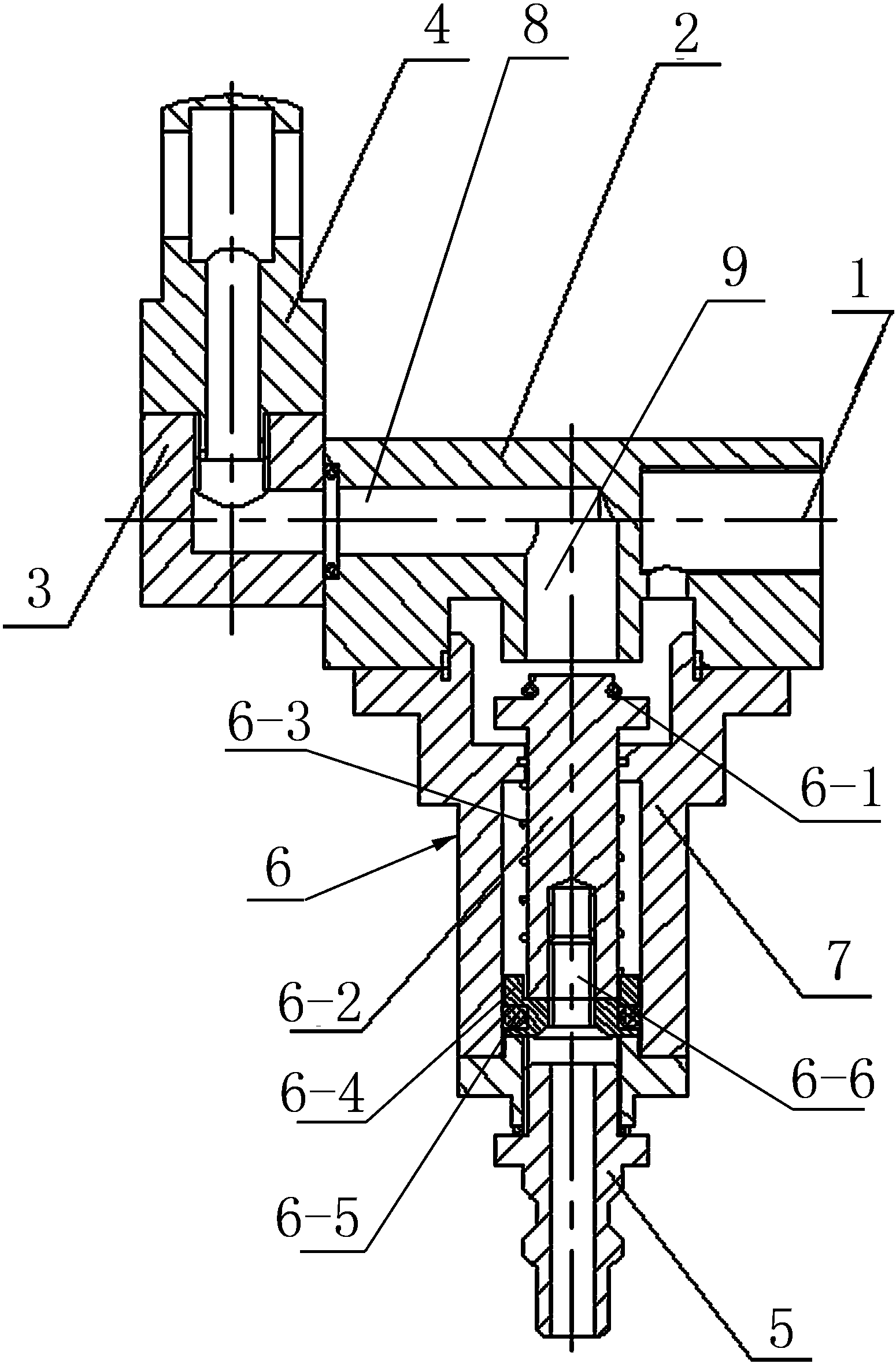

[0013] As shown in the accompanying drawing, a device for forced flameout of an engine includes an oil and gas control block 2, and the oil and gas control block is provided with an oil inlet oil passage 1, an oil outlet oil passage 8 and a control oil passage 9, forming a structure similar to a three-way valve. The control oil passage 9 cooperates with the high-pressure gas control valve 6 to realize the connection and cut-off of the oil inlet passage 1 and the oil outlet passage 8, the oil and gas control block 2 and the oil outlet block 3 are fixedly connected by fastening bolts, and the oil outlet The block 3 and the oil outlet joint 4 are fixedly connected by fastening bolts, and the oil outlet block 3 and the oil outlet joint 4 have oil passages inside and communicate with the oil outlet oil passage 8 of the oil and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com