A glass recycling system

A recycling system and glass technology, applied to chemical instruments and methods, grain processing, solid waste removal, etc., can solve the problems of reduced tension of the conveyor belt, cullet transmission, cullet blockage, etc., to prevent flying cars and debris uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

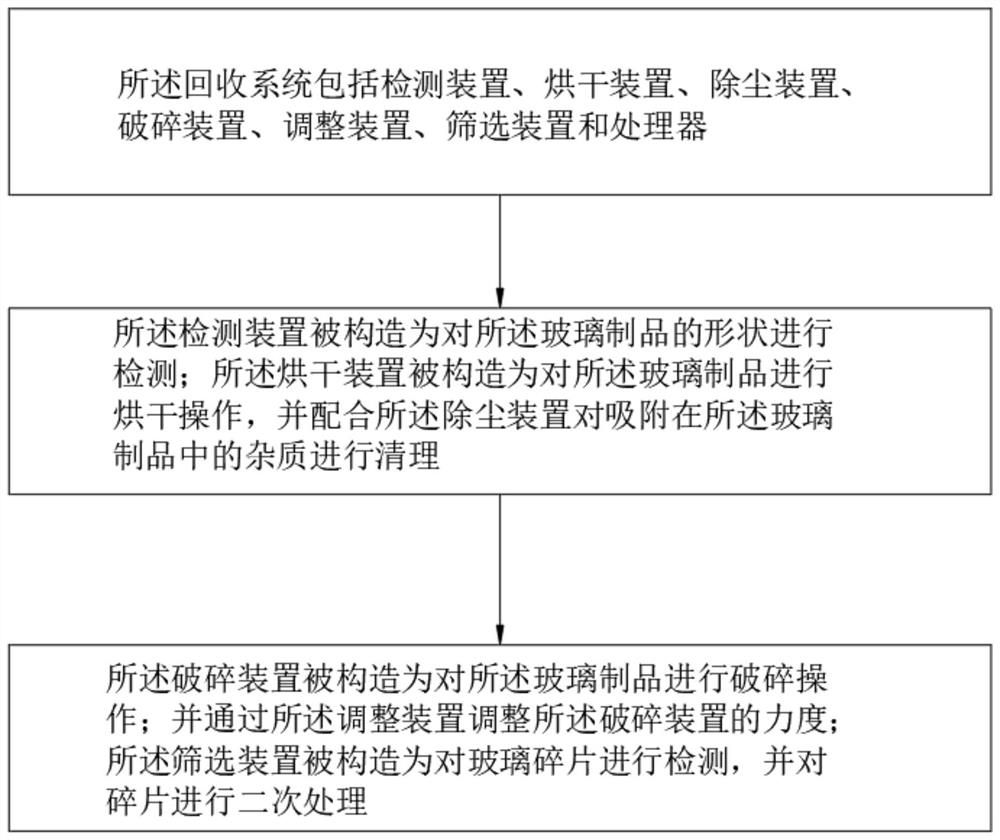

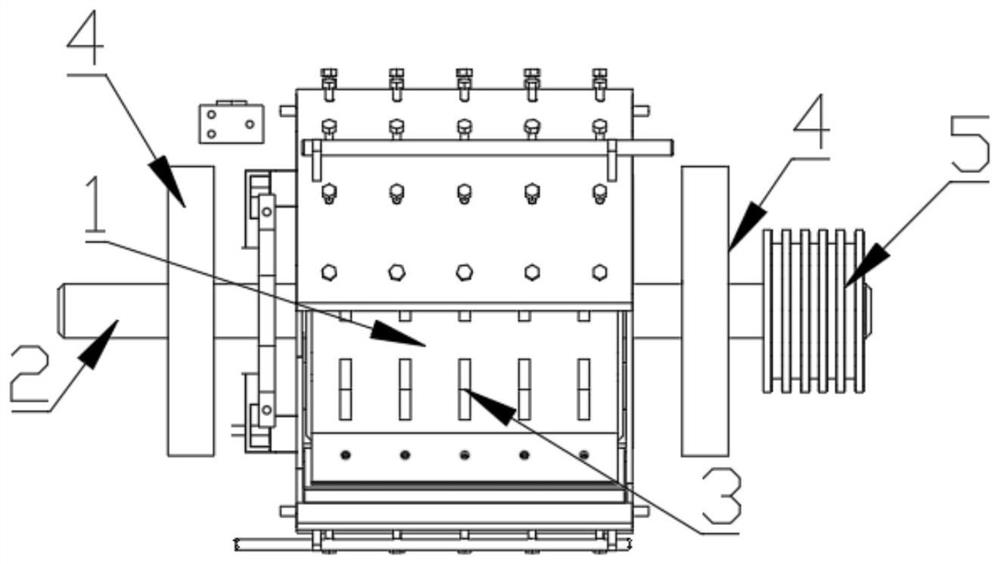

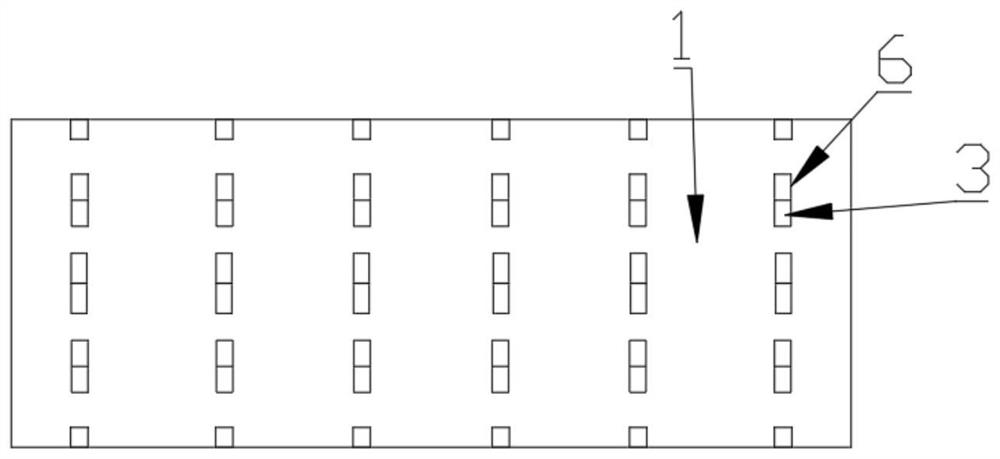

[0035] Embodiment 1: A glass recovery system, the recovery system includes a detection device, a drying device, a dust removal device, a crushing device, an adjustment device, a screening device and a processor, and the detection device is configured to monitor the glass products The shape is detected; the drying device is configured to dry the glass products, and cooperate with the dust removal device to clean up the impurities adsorbed in the glass products; the crushing device is configured to dry the glass products The above-mentioned glass products are broken; and the strength of the breaking device is adjusted through the adjusting device; the screening device is configured to detect glass shards and perform secondary processing on the shards; the detection device includes a detection probe, A transportation mechanism and a data collection unit, the detection probe is configured to be connected to the data collection unit, and the data of the glass product is collected th...

Embodiment 2

[0036] Embodiment 2: This embodiment should be understood as at least including all the features of any one of the foregoing embodiments, and further improvements are made on the basis of it. Specifically, a glass recovery system is provided, and the recovery system includes a detection device, a drying Drying device, dust removal device, crushing device, adjustment device, screening device and processor, the detection device is configured to detect the shape of the glass product; the drying device is configured to dry the glass product Dry operation, and cooperate with the dust removal device to clean up the impurities adsorbed in the glass products; the crushing device is configured to crush the glass products; and adjust the crushing device through the adjustment device Intensity; the screening device is configured to detect glass shards and perform secondary processing on the shards; specifically, the detection device is connected with the drying device, the dust removal de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com