Position control method of servo motor

A technology of servo motor and control method, applied in the direction of position/direction control, electrical program control, non-electric variable control, etc., can solve problems such as inability to adapt to high-precision counting, inability to adapt to high-speed counting, inability to adapt to real-time requirements, etc., to meet the requirements The effect of reducing and increasing the number of counts and fast counting speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

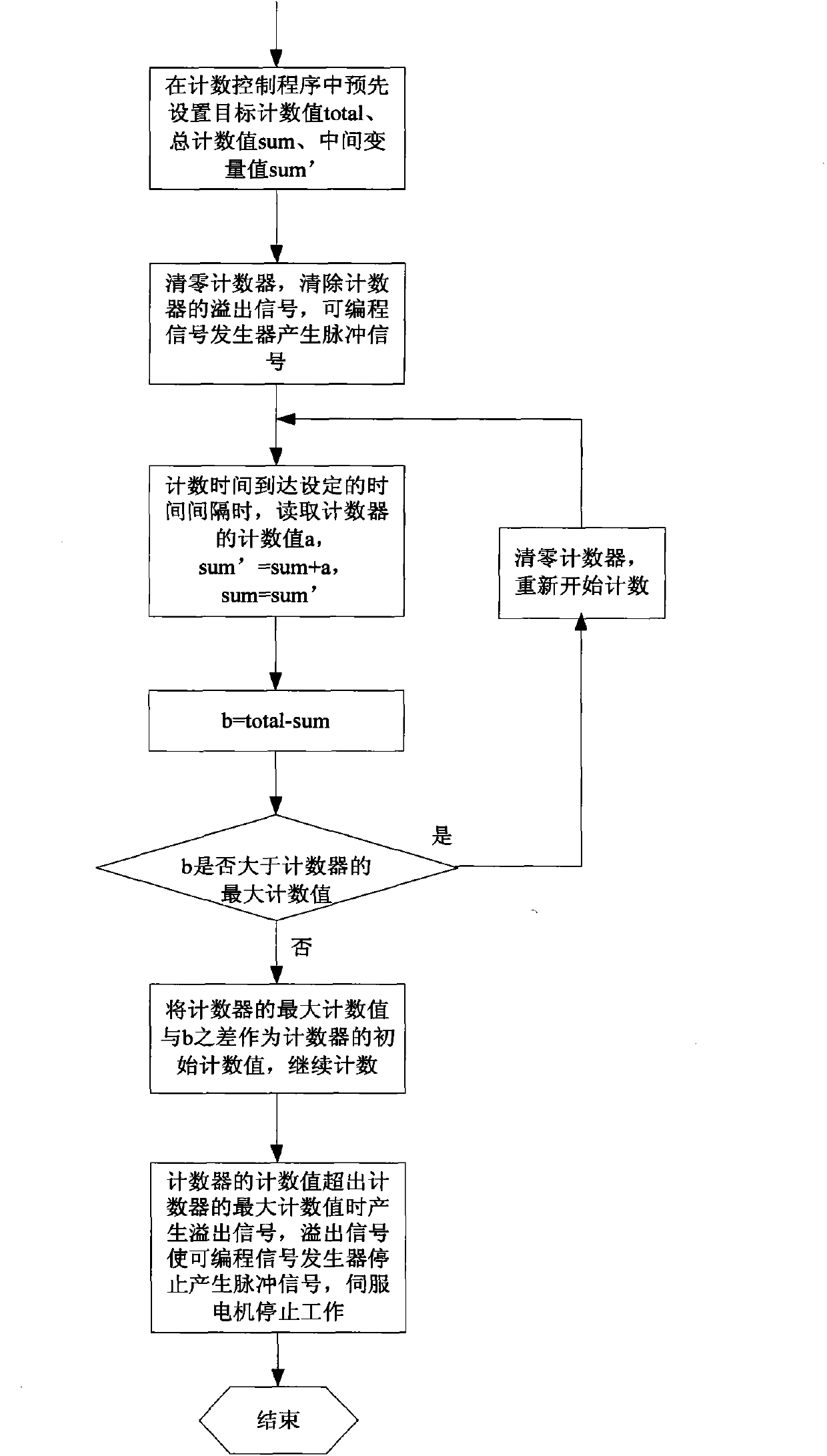

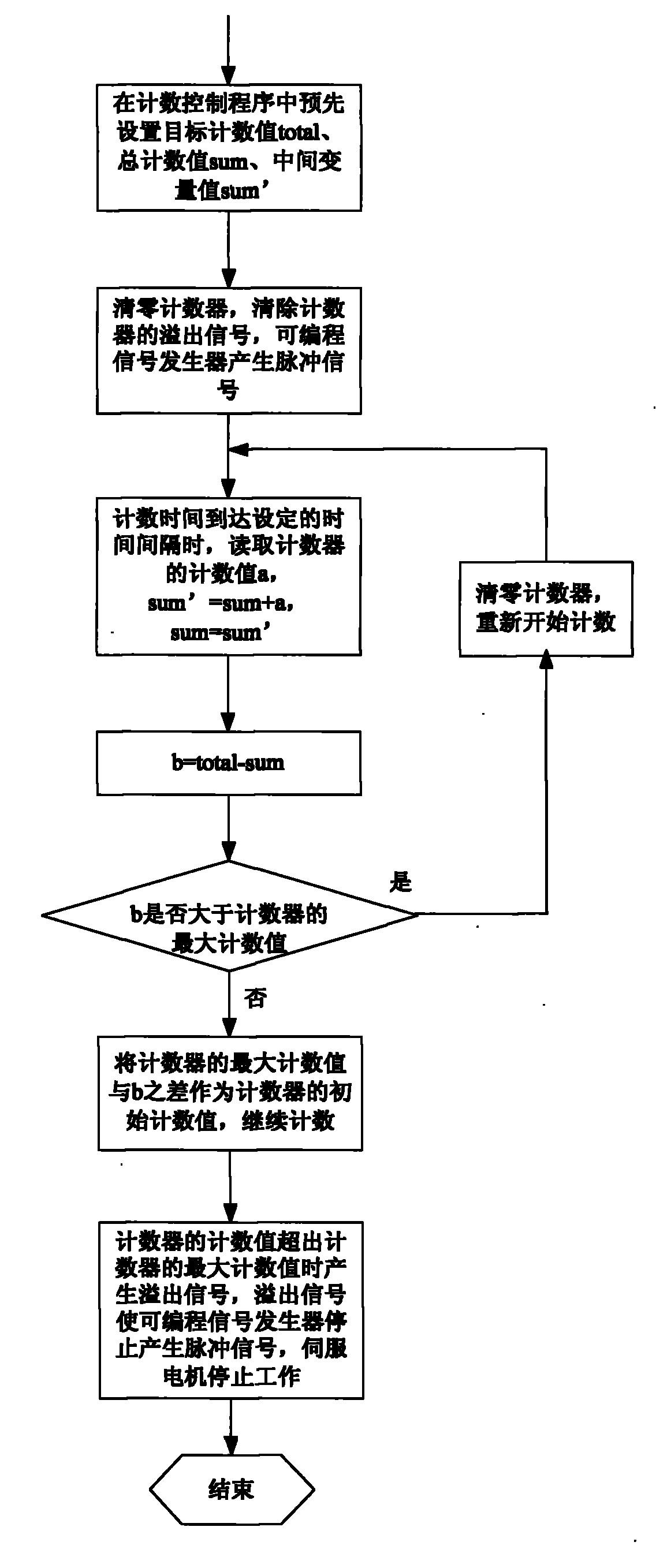

[0020] When controlling the position of the servo motor, if it is implemented purely using a counter, the counting speed will decrease with the increase of the number of counter digits, and at the same time it will increase the hardware cost. If it is implemented purely using a counting control program, there will be Counting accuracy is not high. In order to increase the counting speed while ensuring the counting accuracy, to meet the requirements of high-precision and high-speed counting, and reduce hardware costs, the invention proposes a servo motor position control method.

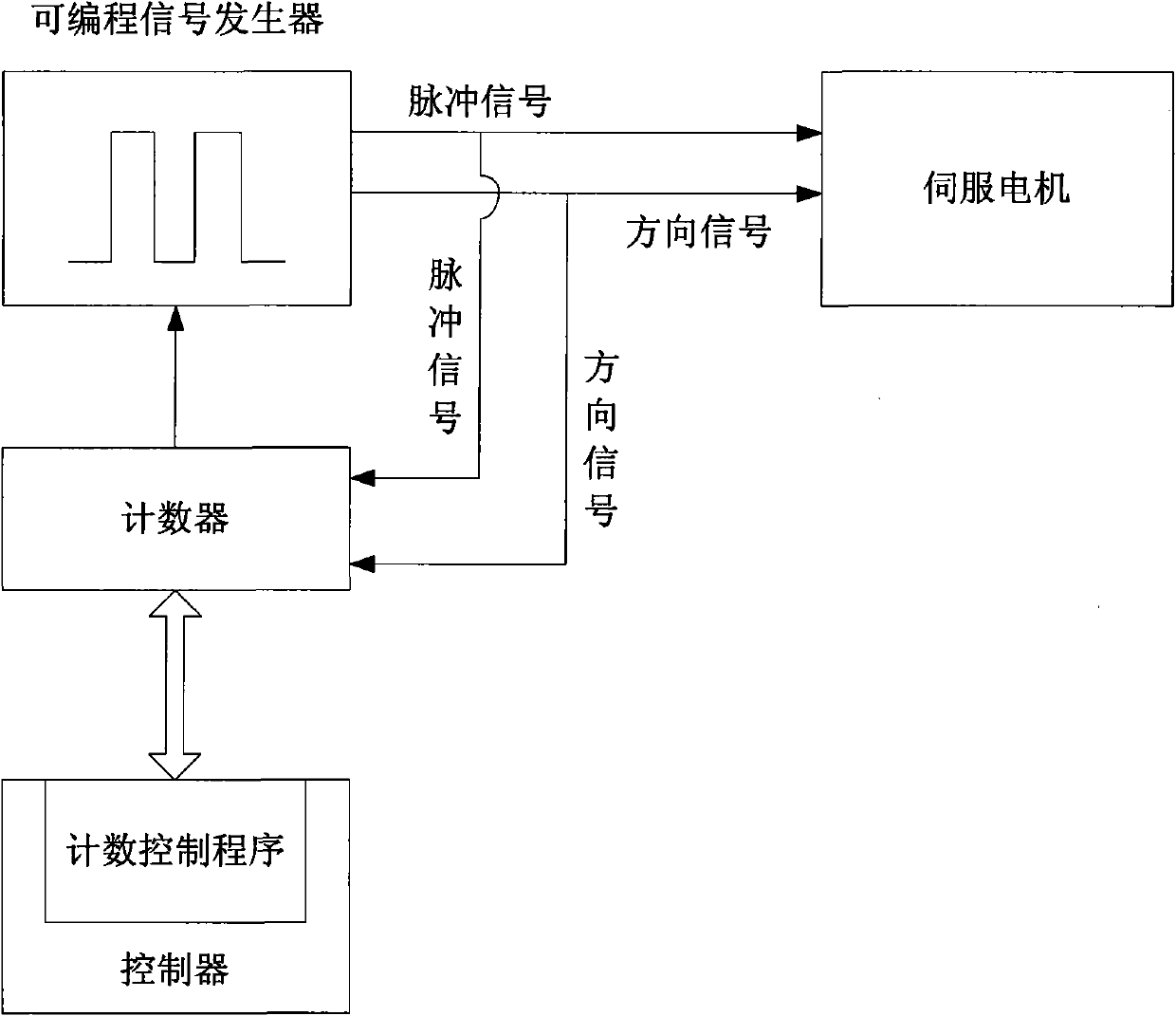

[0021] The inventive method is used to connect the programmable signal generator of pulse signal with servomotor and counter respectively, then counter is connected with a controller with counting control program, as figure 1 As shown, the programmable signal generat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com