Downward transport belt conveyor energy-saving braking system

A brake system and belt conveyor technology, applied in conveyors, transportation and packaging, etc., can solve the problems of large motor starting force, low power of belt conveyor, waste of energy, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

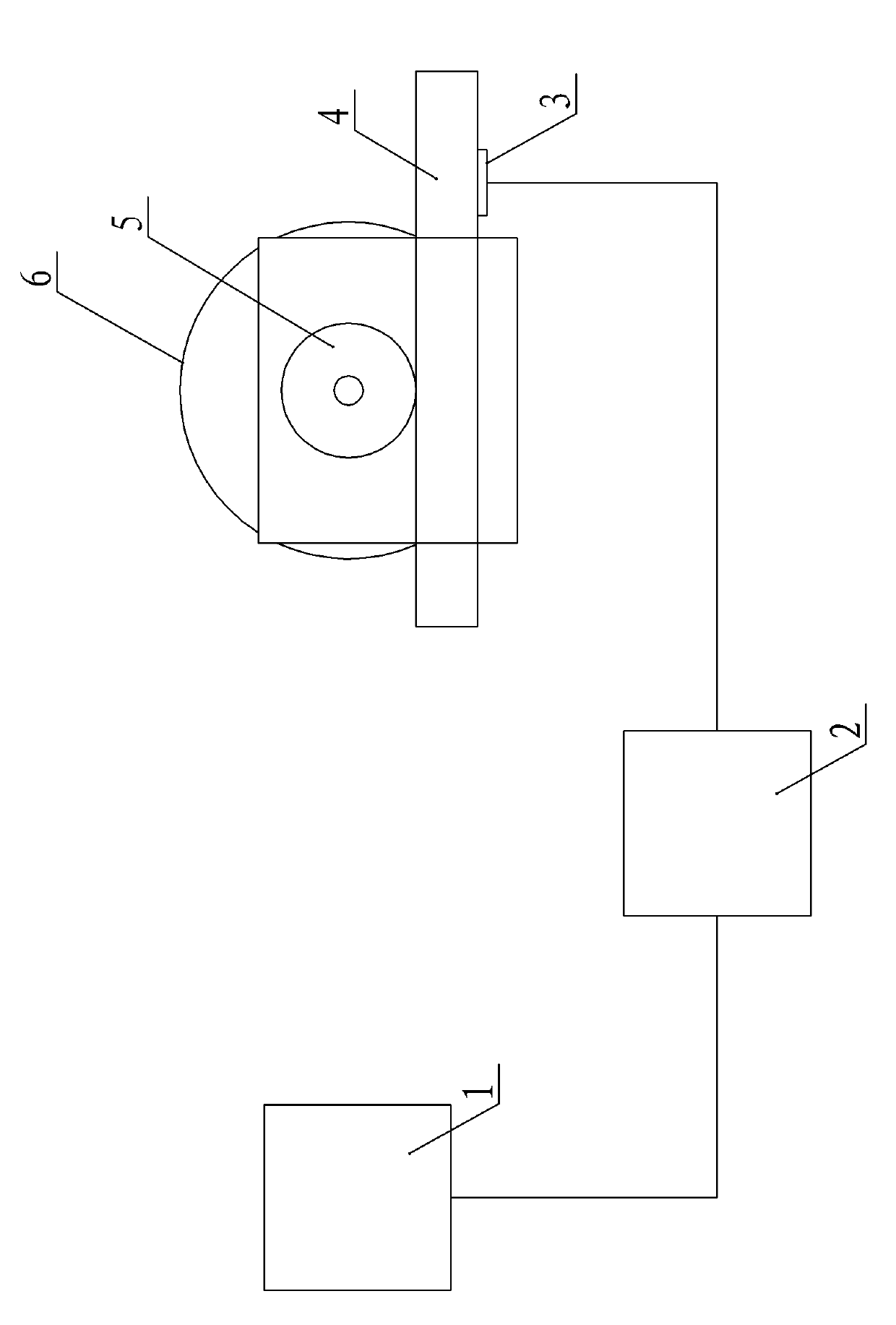

[0010] Example: see figure 1 In the figure, an energy-saving braking system for a down-conveying belt conveyor includes a low-power motor, a worm gear reducer, a belt drive drum, and a brake device. The motor shaft is connected to the worm of the worm gear reducer, and the drive roller is connected to the worm gear The worm gear of the reducer; a tensile stress sensor is arranged in the axial direction of the worm, and the system also includes a control module, and the control module is respectively connected to the tensile stress sensor and the braking device. The brake device can be selected from various brakes in the prior art, and it only needs to be controlled by a circuit to meet the requirements. The control module at least includes a memory, an analog-to-digital converter, and an arithmetic unit.

[0011] The braking system first uses the worm gear reducer to start. This reducer has a large speed ratio and can generate relatively large torque on the turbine, so that t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com