Abrasive disc type wind turbine

A wind turbine and grinding disc technology, which is applied to wind turbines, wind turbine combinations, wind turbine control and other directions, can solve the problems of wind turbine blades that cannot always be in the windward state, the blade running mode is not stable enough, and the power generation cannot be performed. Achieve the effect of low noise, small vibration, and ensure safe use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

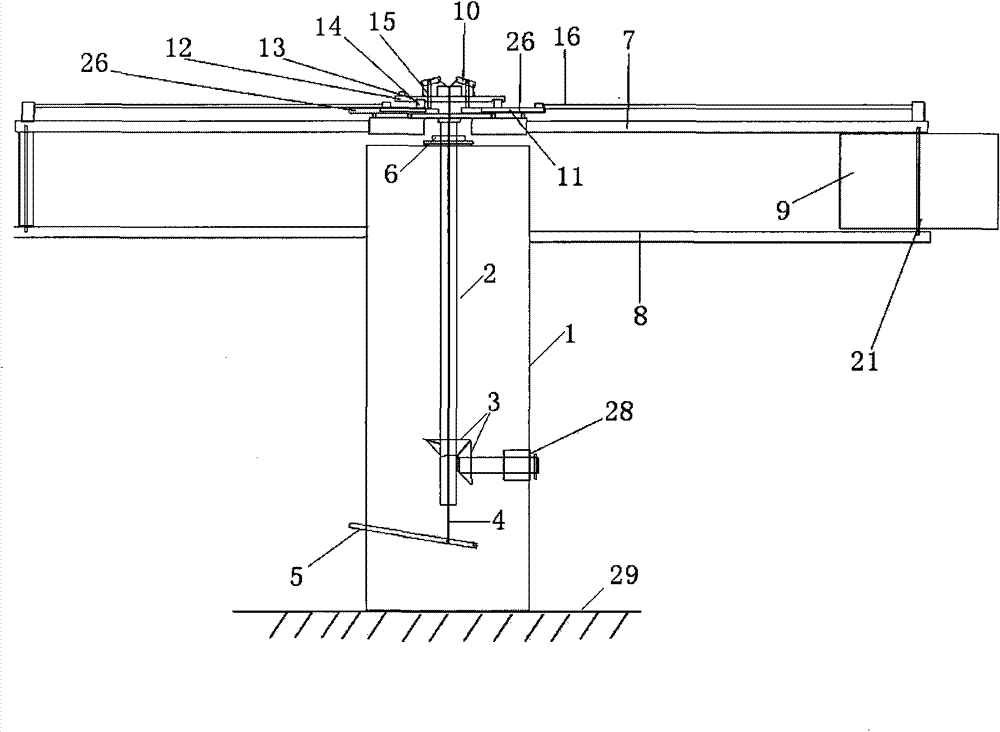

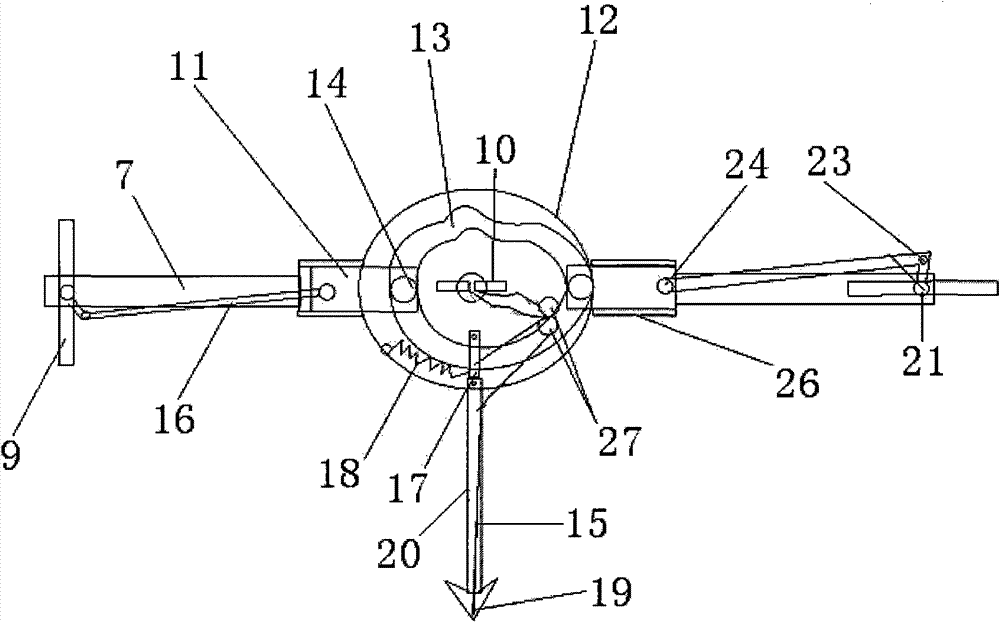

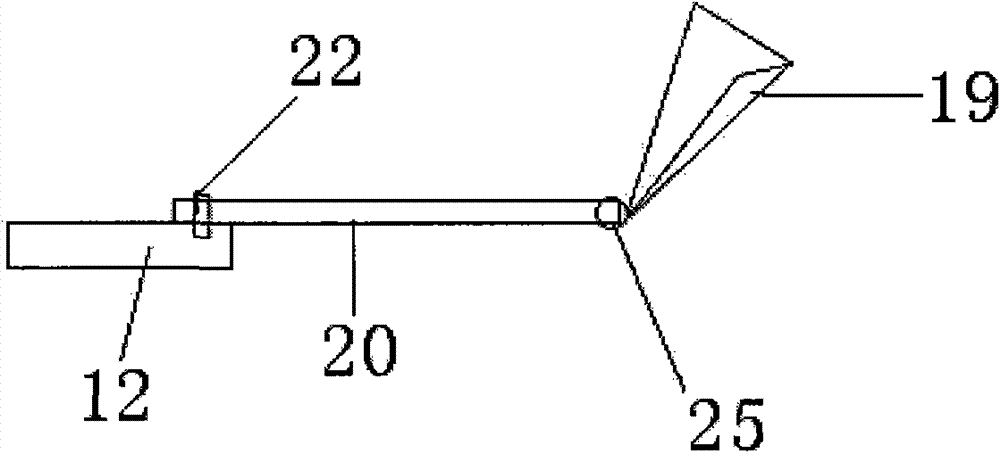

[0022] see figure 1 , figure 2 , image 3 , a kind of disc type wind power machine of the present invention, by column 1, power rotating shaft 2, bevel gear 3, brake wire 4, handbrake 5, bearing 6, main support 7, support 8, blade 9, ejector rod 10, slide block 11. Wind direction control panel 12, guide groove 13, bearing 14, speed control cable 15, crankshaft 16, speed control block 17, spring 18, empennage 19, connecting rod 20, shafts 21, 22, 23, 24, 25, carriage 26. The pulley 27 is composed of a generator 28, wherein the column 1 is fixed on the foundation 29, the power transmission shaft 2 is set at the center of the column 1, and the lower part of the power transmission shaft 2 is connected to two meshing bevel gears 3, the bevel gear 3 The shaft is connected with the generator 28, the center of the power transmission shaft ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com