Self-adaptive independent cooling method for material grabbing machine and excavator and system

An independent cooling and cooling system technology, applied in the direction of engine cooling, machine/engine, coolant flow control, etc., can solve problems such as shortage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

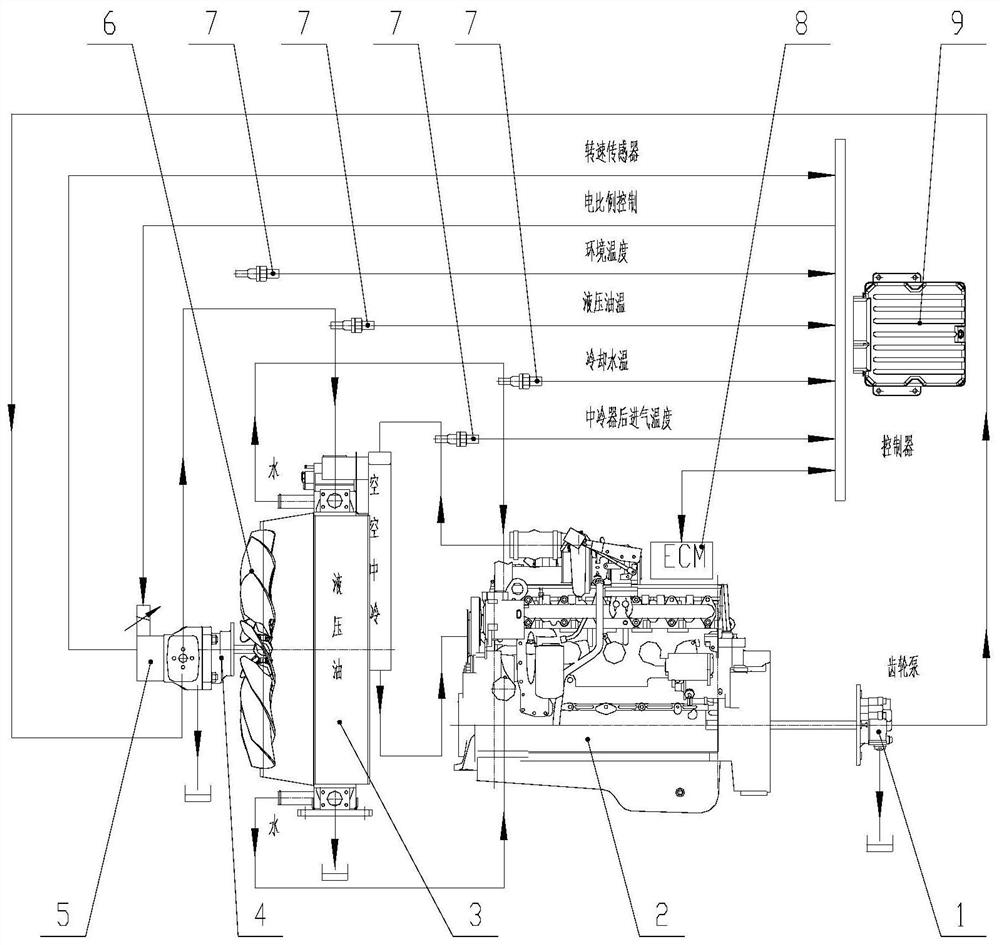

[0040] see figure 2 As shown, the present embodiment provides a self-adaptive independent cooling method for grabbers and excavators, comprising the following steps:

[0041] 1) Determine the fan speed requirements corresponding to various temperatures according to the air intake temperature, cooling water temperature, hydraulic oil temperature and ambient temperature after the intercooler;

[0042] specific:

[0043] First, establish the mapping relationship between the intake air temperature, cooling water temperature, hydraulic oil temperature, and ambient temperature after the intercooler and the fan speed requirements. The mapping relationship is a parameter data table formulated by the engine manufacturer according to the national standard. The parameter data table includes The fan speed corresponding to the corresponding temperature value is shown;

[0044] Then, through existing technical means, such as temperature sensor monitoring, real-time data of intake air tem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com