Double-wheel pump

A technology of sheave wheel and vane wheel, which is used in the field of fluid extraction (pump) or equipment that outputs power with pressurized fluid, which can solve the problems of large mechanical loss, low efficiency and high energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

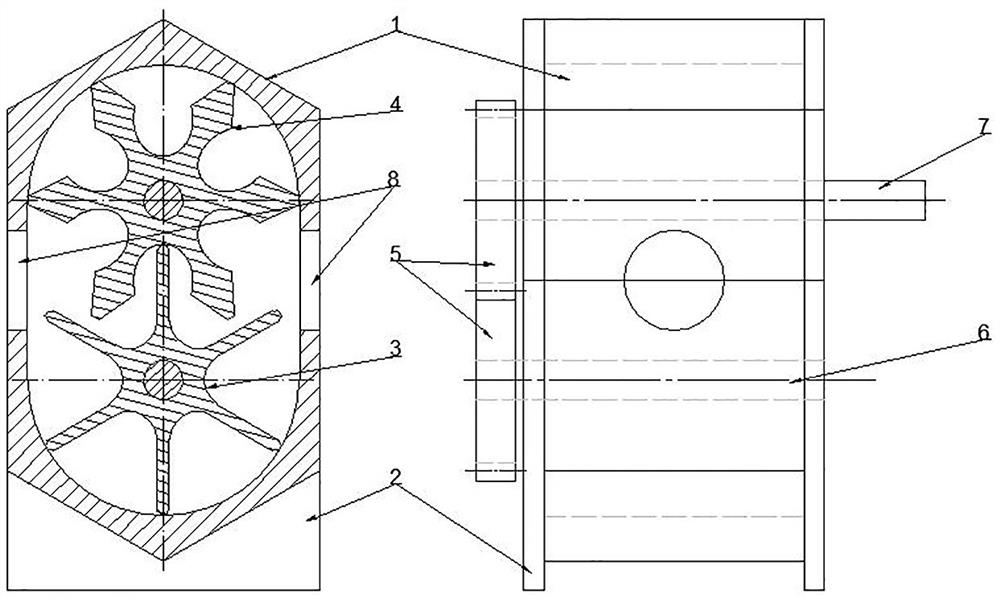

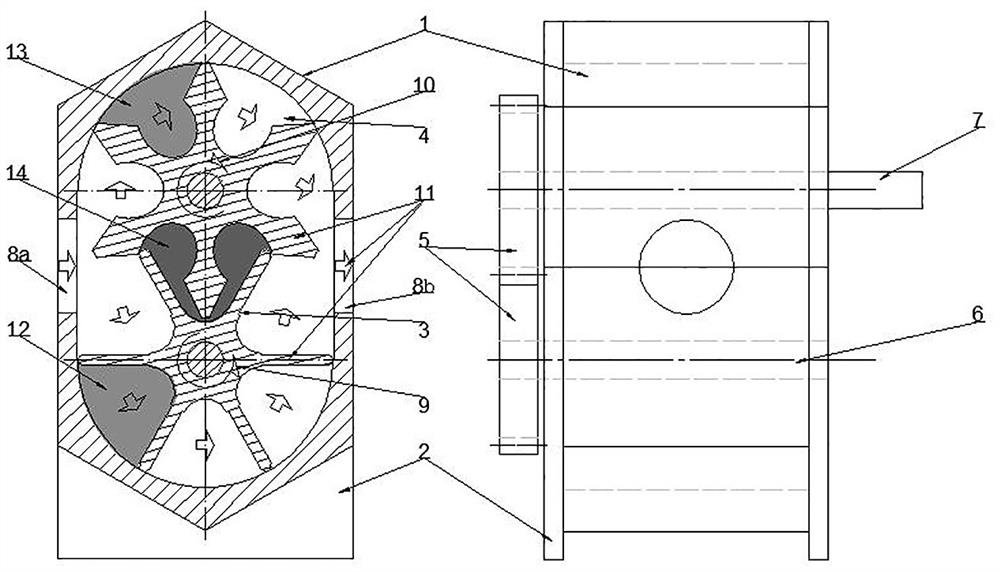

[0023] like figure 1 As shown, this embodiment shows a double-wheel pump using a pair of gears with the same size as the transmission mechanism. The cylinder body 1 adopts a cylinder body structure composed of two circular arc segments whose cross-sectional shape is the inner wall transitioning with a tangent line. It is mainly composed of a cylinder Body 1, two cylinder heads 2, a vane wheel 3, a sheave 4, a gear transmission mechanism 5, a vane wheel shaft 6, a sheave shaft 7 and the like.

[0024] as attached figure 1 , figure 2 As shown, the cylinder body 1 is a structure whose inner wall section is formed by two arc sections transitioned by a tangent line or an arc line. 1 The centers of the two arcs are set eccentrically; the rotation centers of the vane wheel 3 and the rotating shaft 6, the sheave 4 and the rotating shaft 7 are respectively concentric with the arc centers of the two arcs of the cylinder body 1; the cylinder body 1 has a fluid inlet 8a and an outlet 8...

Embodiment 2

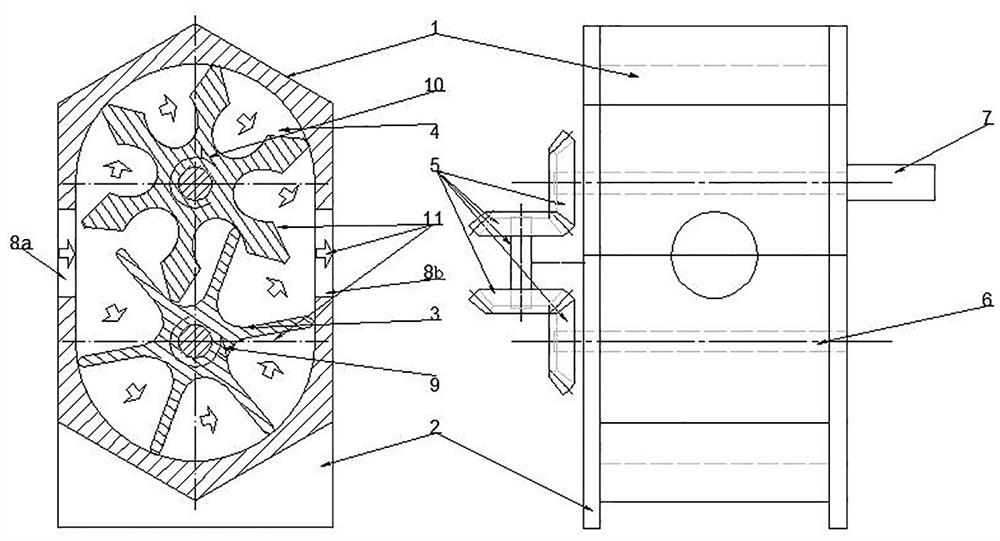

[0029] This embodiment is a power device powered by pressurized liquid, as attached image 3 As shown, the equipment configuration of this embodiment is consistent with that of Embodiment 1, and the difference from Embodiment 1 is that the synchronous transmission mechanism 5 adopts the structure of a bevel gear plus a transmission shaft, and the rotating shaft 7 is a power output shaft.

[0030] The working principle of this embodiment:

[0031] Pressurized liquid is input at the entrance of the equipment; on the side of the inlet 8a, the outer edge of the vane wheel 3 moves to contact the inner wall of the cylinder body 1, and to the vane on the side of the vane wheel 3 outlet 8b, the vane wheel 3 generates a positive torque; and the groove of the groove wheel 4 The blades of the blade wheel 3 in contact generate a reverse torque; the two torques are equal in magnitude and opposite in direction, and the blade wheel 3 is in a balanced state. The outer edge of the vane 4 of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com