Metal plate welding clamp

A technology for welding fixtures and metal sheets, applied in welding equipment, auxiliary welding equipment, metal processing equipment, etc., can solve problems such as inaccurate positioning, unstable clamping, and inconvenient operation, so as to improve production efficiency, reduce welding deformation and Effect of residual stress and labor reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The specific embodiments of the present invention will be described in further detail below in conjunction with the drawings and specific embodiments. The following examples or drawings are used to illustrate the present invention, but are not used to limit the scope of the present invention.

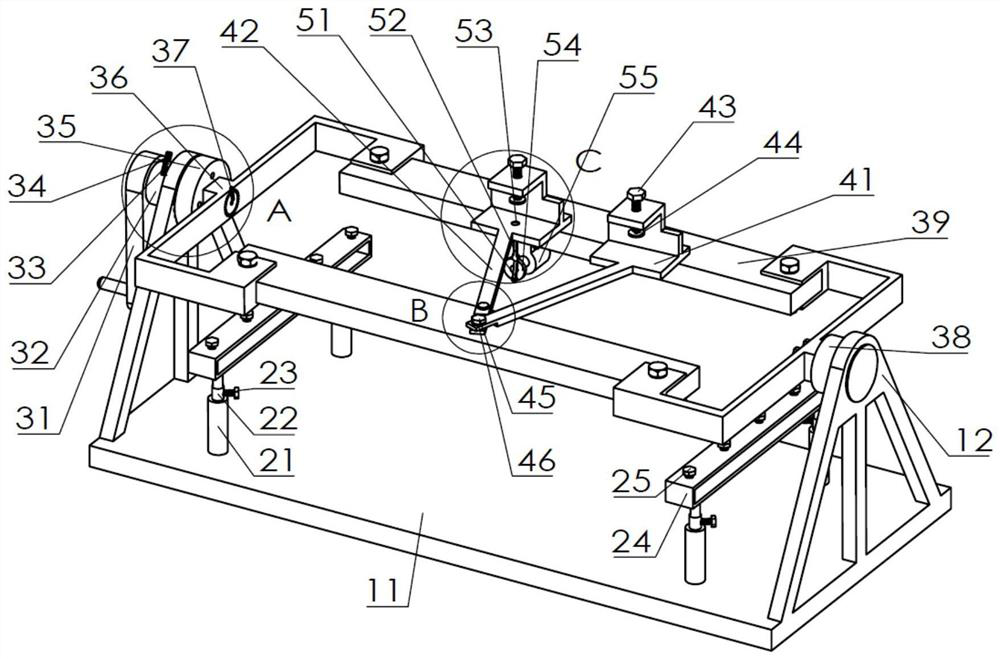

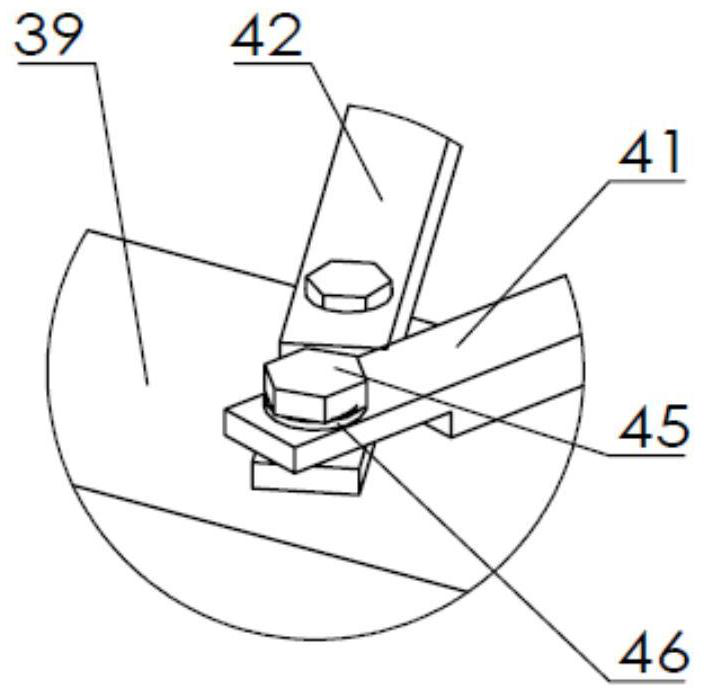

[0040] see Figure 1 to Figure 12 , The invention provides a sheet metal welding fixture, the fixture device mainly includes a weldment support module, a weldment anti-deformation control module, a weldment rotation positioning module, a weldment clamping and fixing module, and a weldment vertical positioning module.

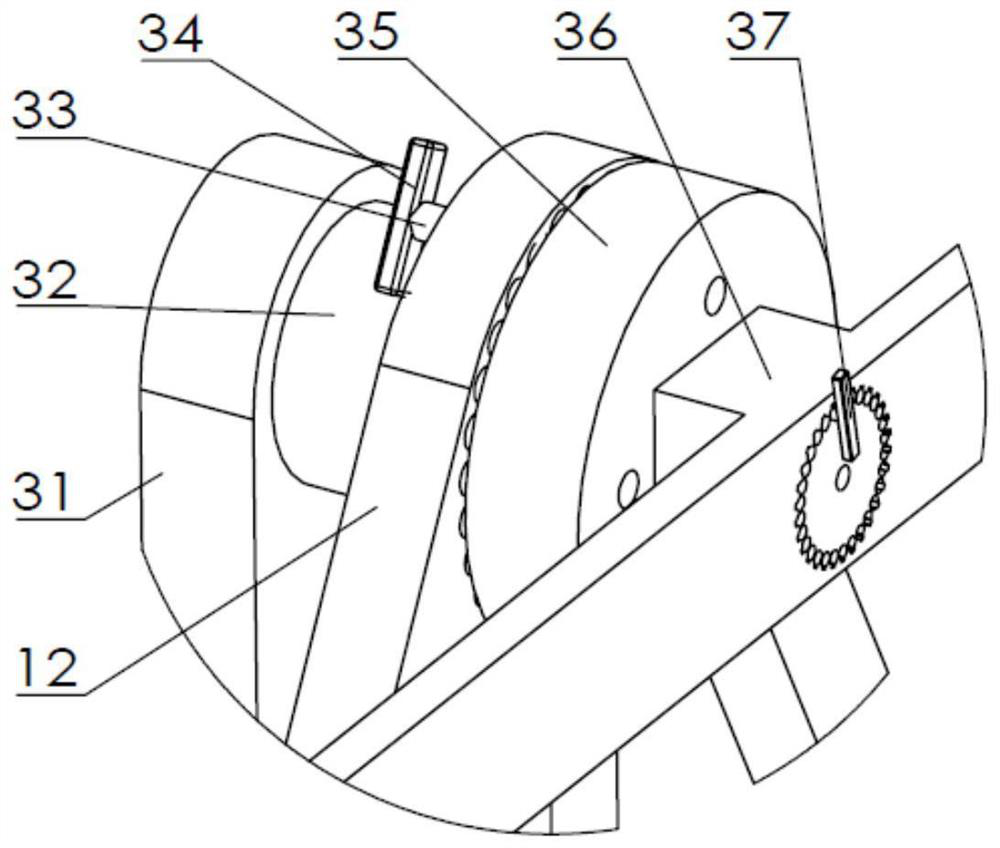

[0041] The weldment support module is composed of a horizontal bottom plate 11 and two side rib plates 12, and equal-diameter through holes are provided on the side rib plates 12 of the clamp body for supporting the shaft 32 and the connecting piece 38, and The left reinforcing rib plate 12 is provided with uniformly distributed and equal-diameter through holes on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com