Jaw clutch

A technology of jaw clutches and protruding teeth, which is applied in the field of clutches, can solve problems such as difficult coupling or disengagement, and achieve the effect of easy connection or disengagement and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] A specific embodiment is enumerated below in conjunction with the accompanying drawings to further illustrate the present invention.

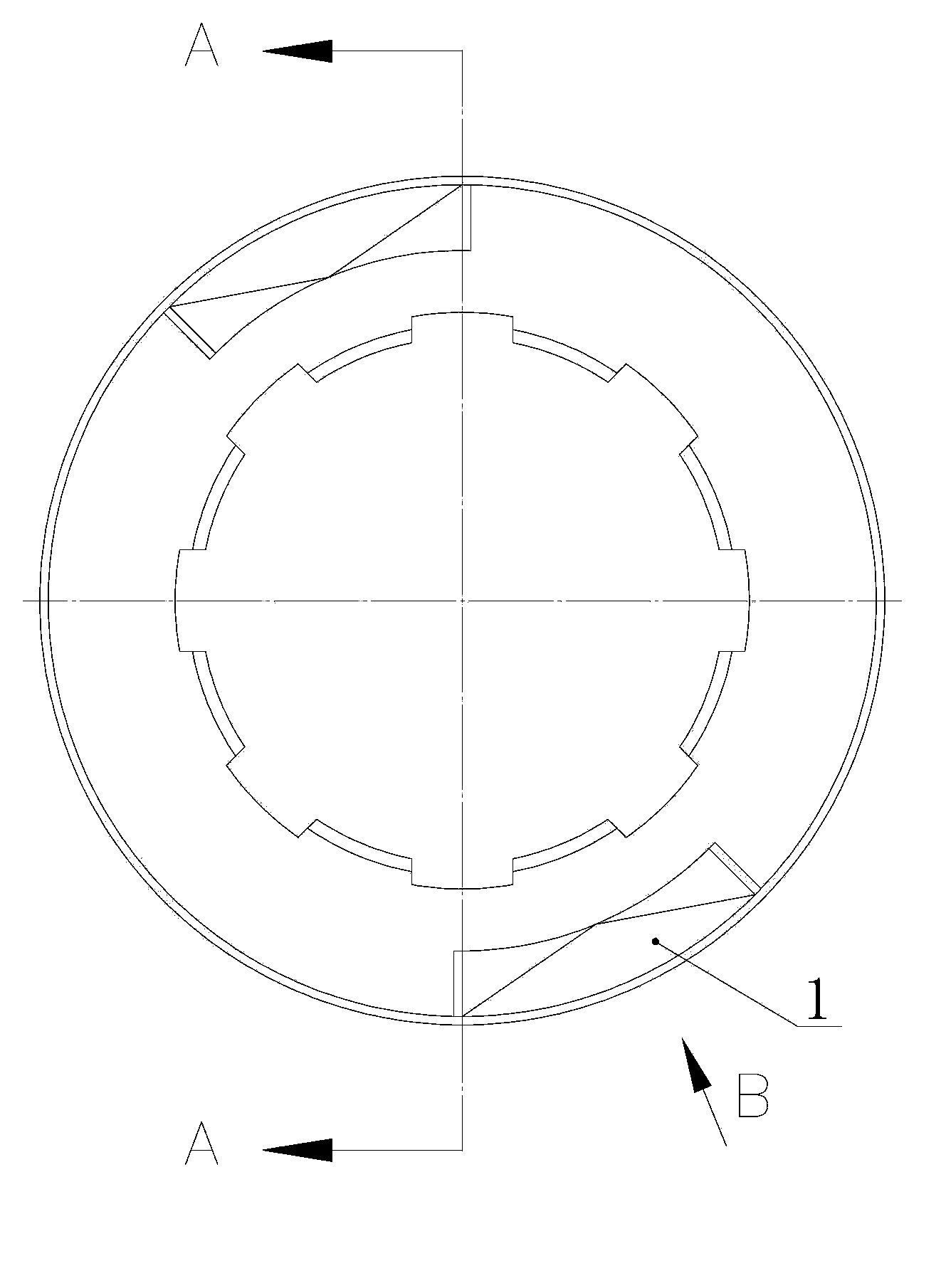

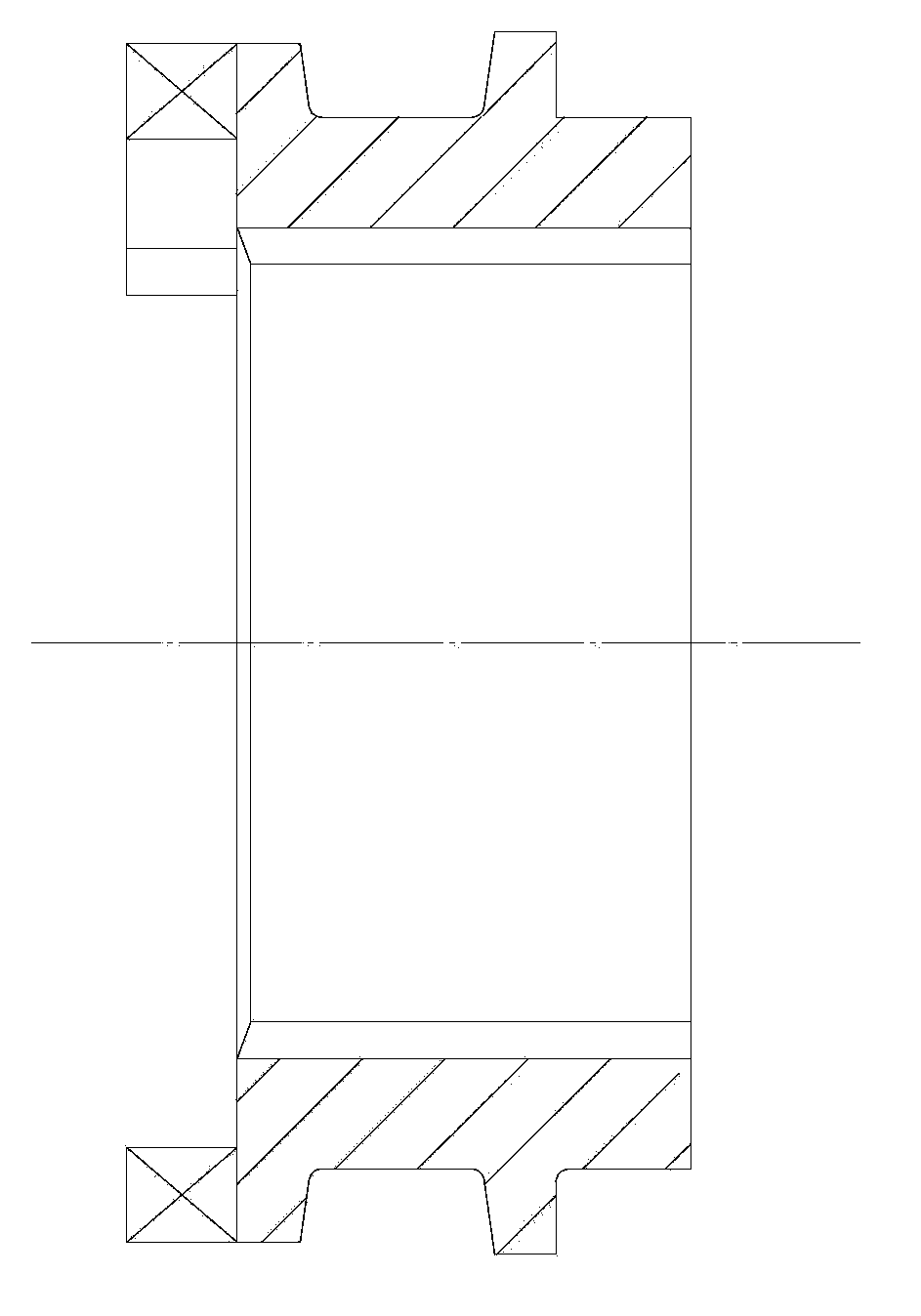

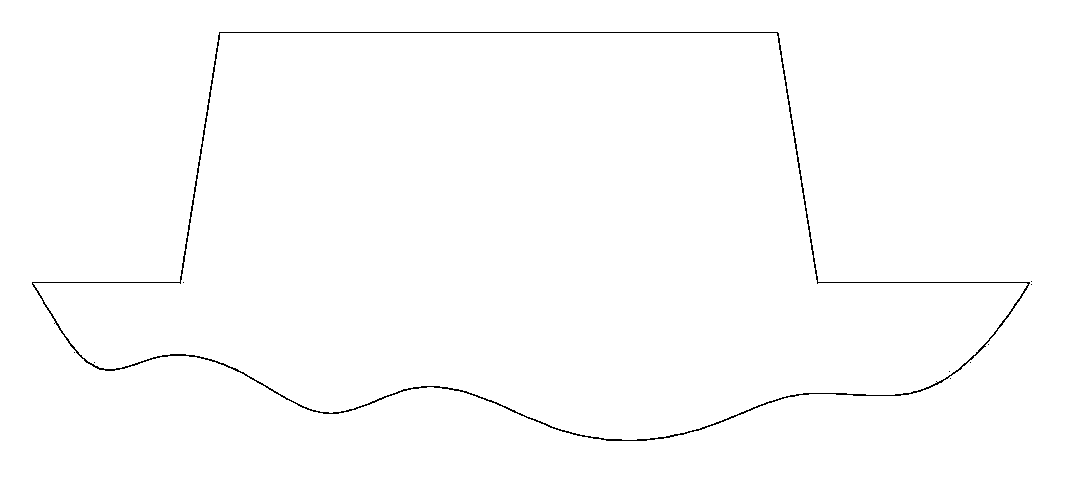

[0014] like Figure 1-Figure 3 As shown, a jaw clutch is a rotating body structure, including internal spline teeth, a large end surface and a small end surface, and the large end surface is provided with not less than two convex teeth 1 evenly distributed in the circumferential direction, and the convex teeth 1 There is an inclined plane on both side surfaces; the angle range between the inclined plane and the large end surface is 91°~99°.

[0015] In this embodiment, the range of the included angle between the slope and the large end surface is preferably 92.85°-93.15°.

[0016] The working principle of this embodiment: there are two protruding teeth in this embodiment, and the jaw clutch is connected with an output device through its internal spline. Under the action of a device, it moves in the axial direction so as to disengage th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle range | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com