Tail end power ventilation device with electric heating

A technology for power ventilation and fans, applied in space heating and ventilation, heating methods, lighting and heating equipment, etc., can solve the problems of loud fan noise, unable to meet the crew heating needs, overflow, etc., and achieve the effect of reducing noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below in conjunction with accompanying drawing, the specific embodiment of the present invention is described in further detail:

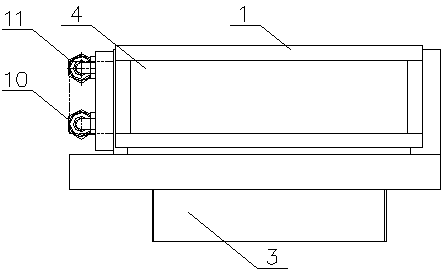

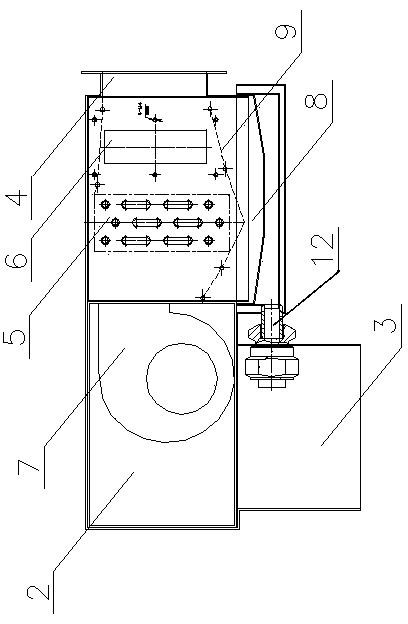

[0016] like Figure 1-2 As shown, a terminal power ventilation device with electric heating includes a coil box 1, a fan box 2, an air return port 3, an air outlet 4, a coil tube 5, an electric heater 6, a fan 7, a water receiving plate 8, a partition 9, Water inlet pipe 10, water outlet pipe 11 and condensation water pipe 12. The front of the coil box 1 is provided with an air outlet 3, and the coil box 1 is horizontally provided with a coil 5, and the water inlet pipe 10 and the water outlet pipe 11 are connected to the left side of the coil 5 and extend out of the coil box 1, and the coil 5 and the Electric heating 6 is installed between the 4 air outlets, a water receiving tray 8 is installed directly below the coil, and a partition 9 is arranged above the water receiving tray. The partition surface is a concave curved surface, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com