Method for monitoring corrosion and predicting service life of bridge

A life prediction and corrosion monitoring technology, which is applied in weather resistance/light resistance/corrosion resistance, measuring devices, instruments, etc., can solve the problems of reducing the timeliness of bridge structure monitoring, inability to effectively monitor long-term corrosion diffusion, and complicated sensor installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described in detail below in conjunction with the drawings.

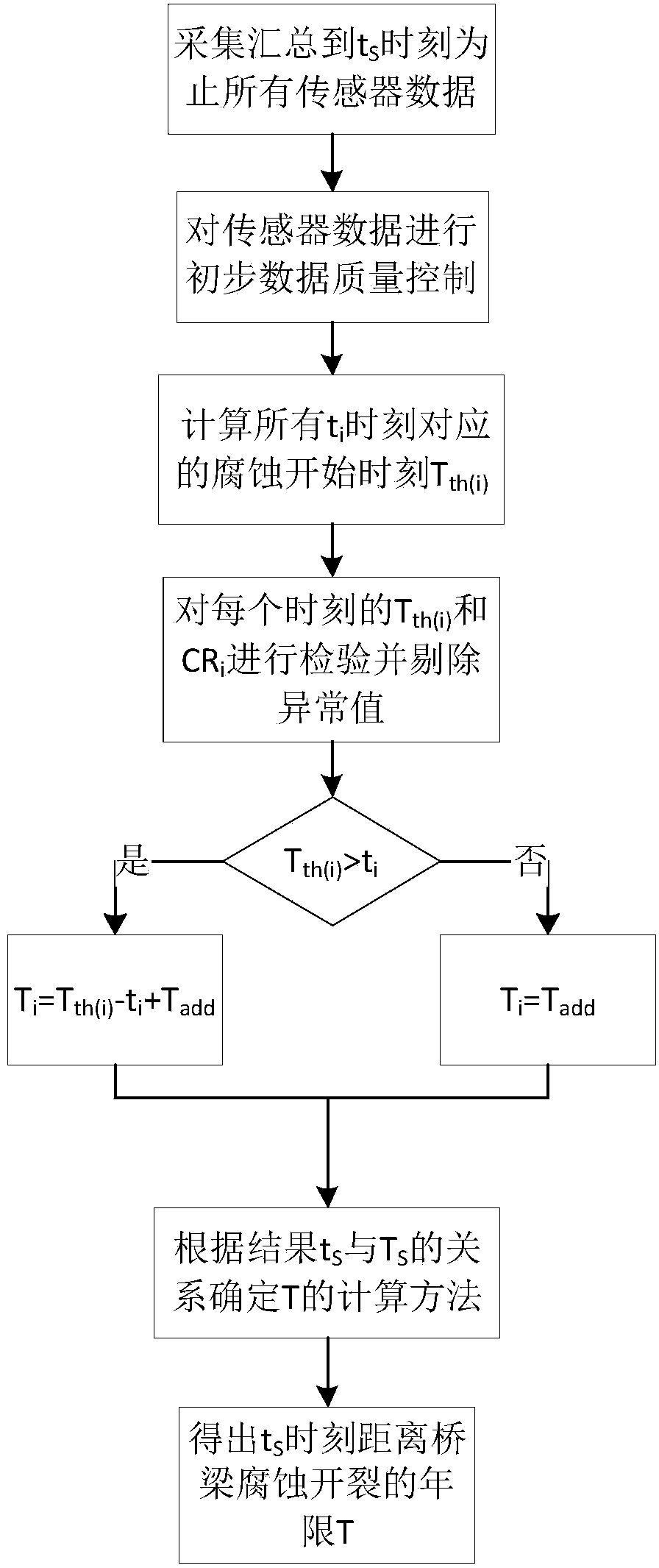

[0040] Such as figure 1 Shown is the overall flow chart of the method of the present invention, including the following steps:

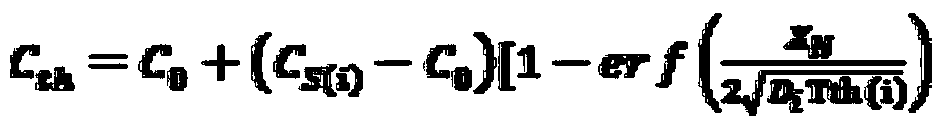

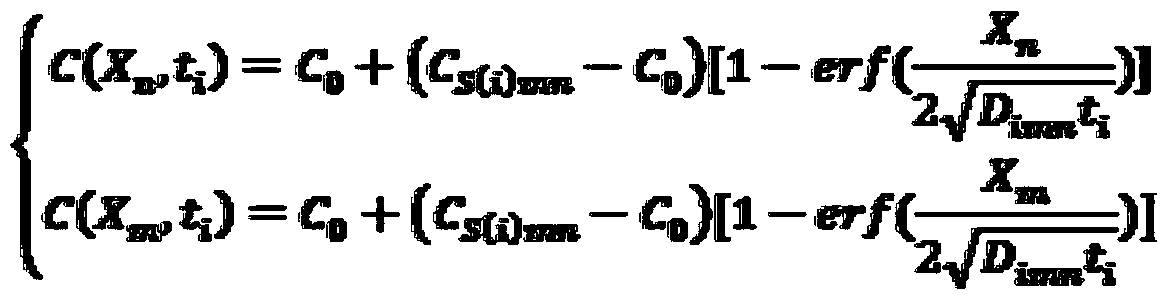

[0041] Step 1) Set up at least three chloride ion concentration sensors in equidistant linear arrangement in the concrete piers of the bridge, record the number of chloride ion sensors as N, and set them at the midpoint of the line between the chloride ion concentration sensors at both ends of the straight line Corrosion rate sensor: The chloride ion sensor and the corrosion rate sensor feedback and record the chloride ion concentration and corrosion rate data at a certain interval. In this implementation method, the sensor is set to feed back a group of data every four hours. The chloride ion concentration sensor can Get time t 1 , T 2 ,...T i …T S Each point of the lower bridge X 1 , X 2 ,...X n …X N The chloride ion concentration at, where t i I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com