Cable tape pasting device

A technology of sticking device and tape, applied in the direction of marking conductors/cables, etc., can solve the problems of increasing the difficulty of jig management, increasing the number of jig managers, and increasing production costs, so as to save manufacturing costs, have a simple structure, and improve production efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

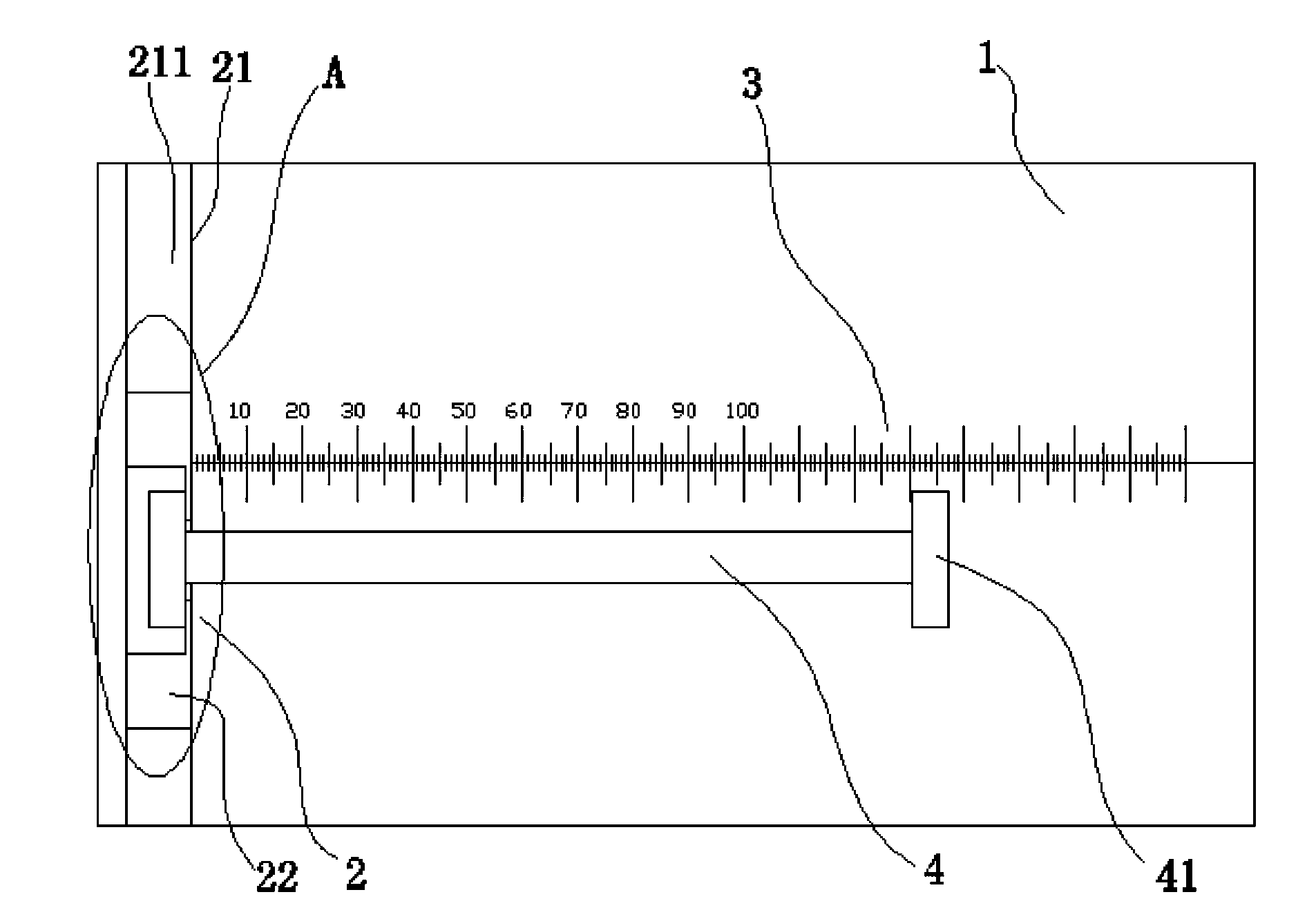

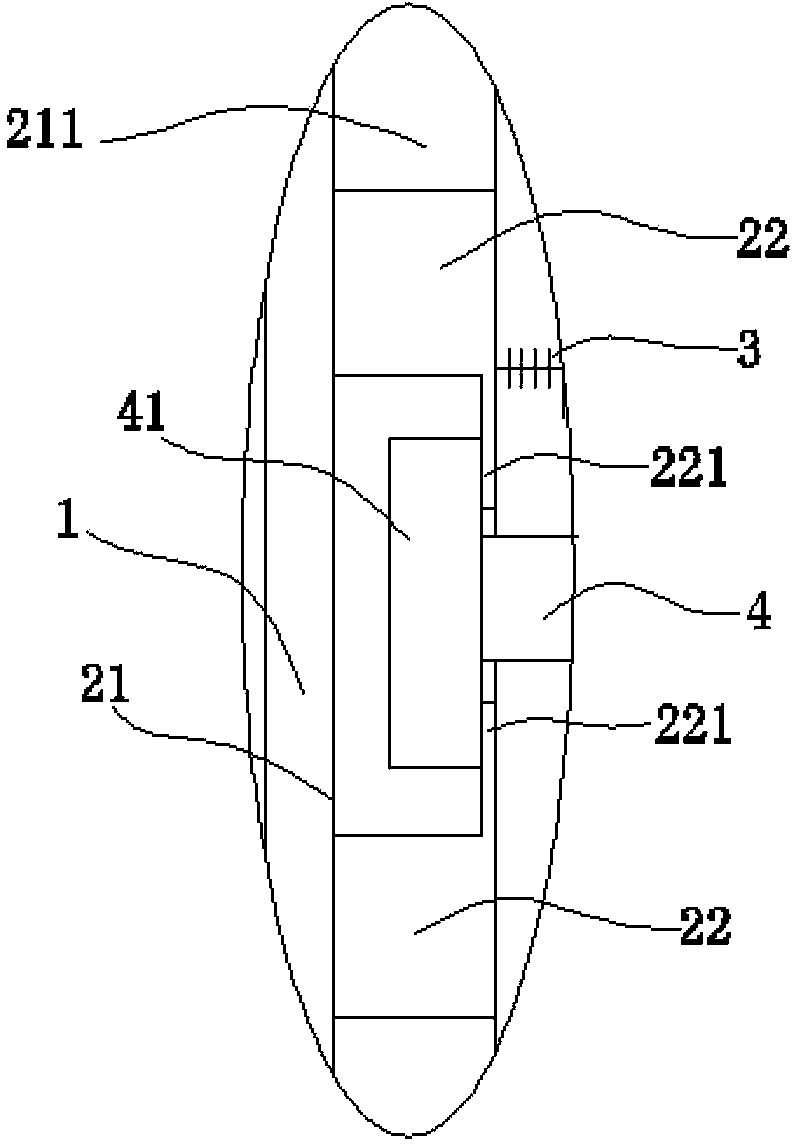

[0012] Example: see figure 1 and figure 2 , a cable adhesive plaster sticking device according to the present invention, which includes a base body 1, on which a limit assembly 2 for positioning the adhesive plaster cable 4 to be pasted and a pasting ruler template 3 with a scale are arranged on the base body 1, The limiting component 2 and the pasting ruler template 3 are arranged vertically to each other.

[0013] The limit assembly 2 includes a guide rail 21 and two limit members 22, the guide rail 21 is arranged on the seat body 1, the two limit members 22 have the same structure, and the two limit members 22 face each other and can slide set in the guide rail 21.

[0014] The adhesive ruler template 3 is arranged on the base body 1 perpendicular to the guide rail 21 .

[0015] An iron plate 211 is provided at the bottom of the guide rail 21 , and a magnet is provided in the limiting member 22 .

[0016] The limiting member 22 is a square block, and a baffle 221 is di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com