Manufacturing method of light-emitting diode light-emitting device

A technology for light-emitting diodes and light-emitting devices, applied in electrical components, circuits, semiconductor devices, etc., can solve the problems of total reflection, light energy loss, etc., to improve the light transmission rate, higher light utilization rate, and reduce a large number of total reflection phenomena. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The manufacturing method of the light-emitting diode light-emitting device provided by the embodiment of the present invention includes the following steps.

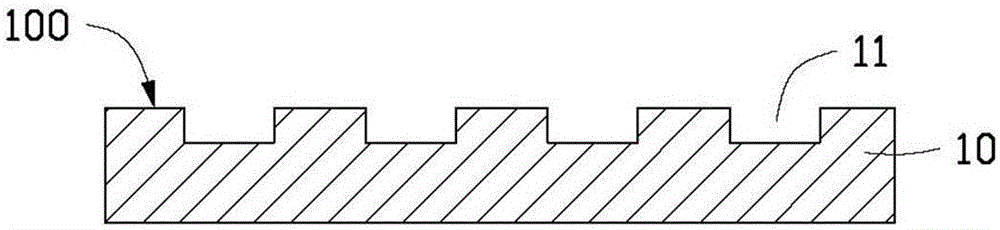

[0017] first step, see figure 1 , providing an optical element 10 comprising a groove 11 .

[0018] The optical element 10 can be a diffusion plate, a lens or a light guide plate, etc., and the number of grooves 11 of the optical element 10 can be single or multiple. see figure 1 , in this embodiment, the optical element 10 is a light guide plate including a plurality of grooves 11, and the plurality of grooves 11 are a plurality of blind holes formed on the light incident side 100 of the light guide plate.

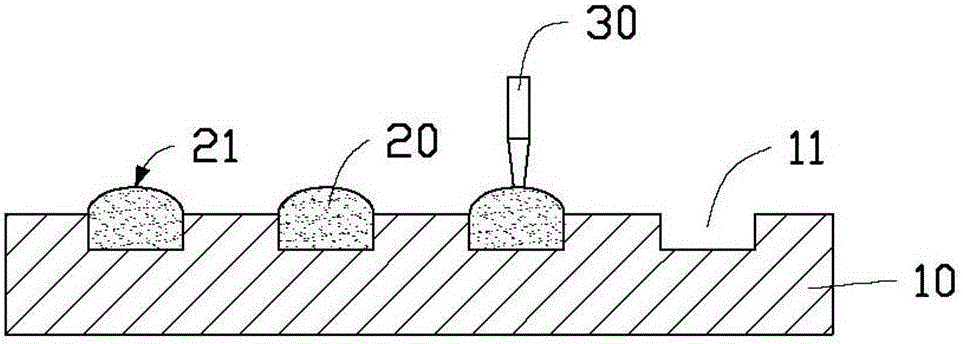

[0019] The second step, see figure 2 , filling the transparent adhesive material 20 into the groove 11 of the optical element 10 .

[0020] The method of dispensing glue can be adopted here, and the syringe 30 of the glue dispensing machine is used to inject the transparent glue material 20 into the groo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com