TM mode dielectric filter

A technology of dielectric filter and resonator, applied in the field of filter, can solve the problems of increasing production difficulty, difficult to reduce the volume, reducing reliability, etc., and achieve the effect of improving Q value, reducing loss and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

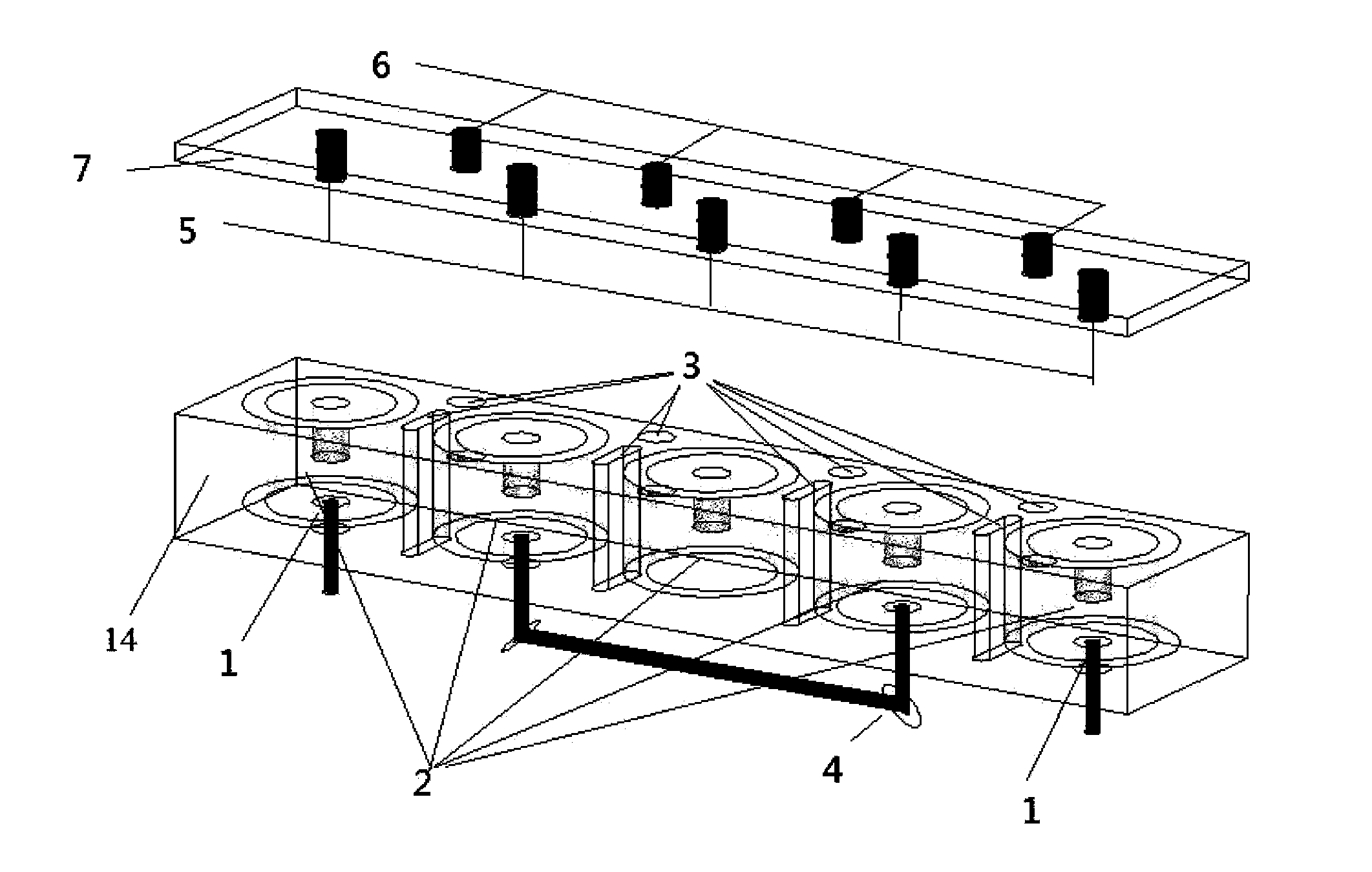

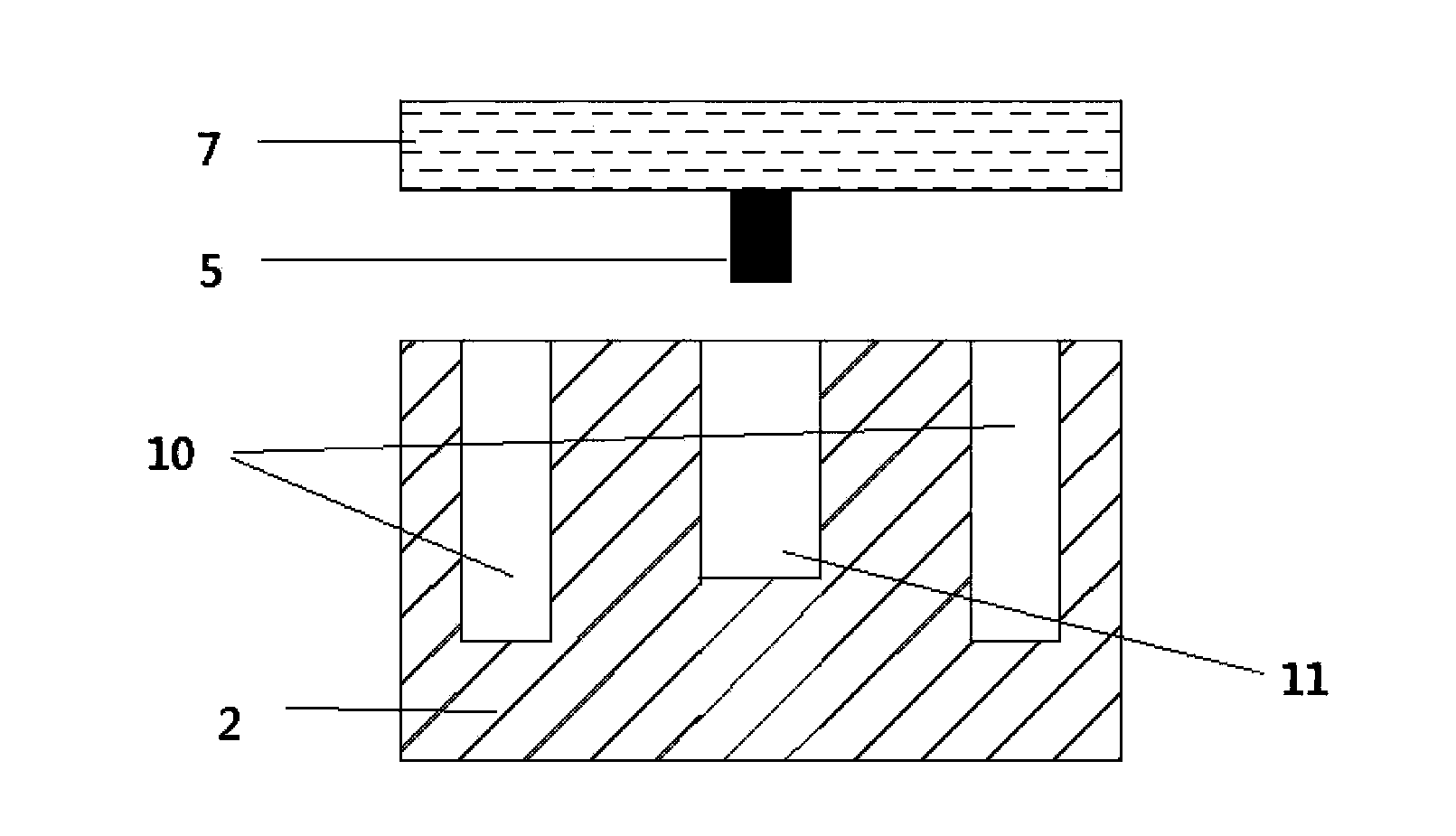

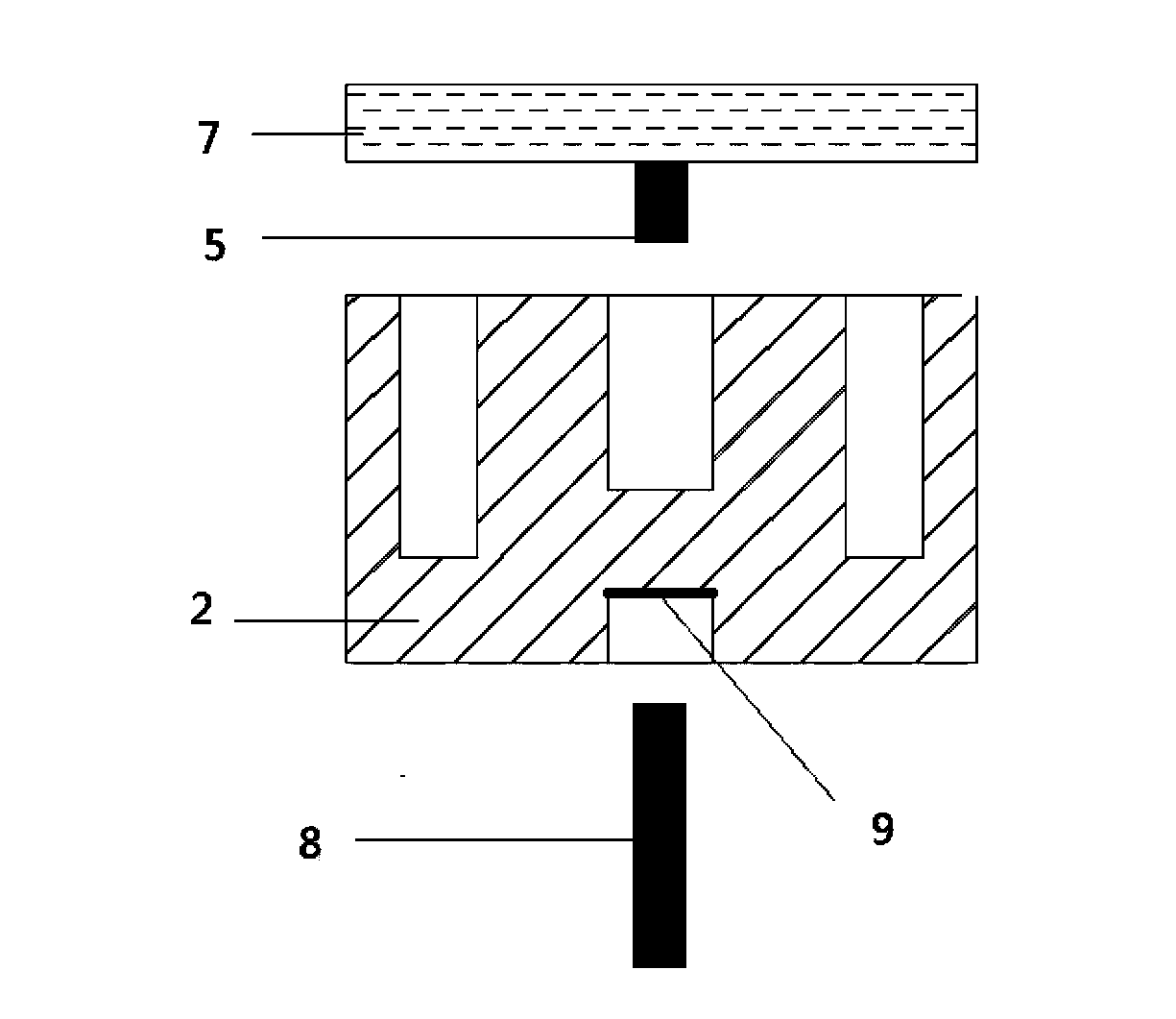

[0019] Example: such as figure 1 As shown, a TM-mode dielectric filter designed in the present invention includes a base 14 , at least three cylindrical resonators 2 arranged axially inside the base 14 and a cover plate 7 arranged on the top of the base 14 . The resonator 2 and the base 14 are integrally formed by TM mode dielectric material; the base 14 is provided with an annular air groove 10 with an open upper end around the cylindrical surface of the resonator 2 .

[0020] There is a frequency adjustment hole 11 on the resonator 2, and an inter-resonator coupling device 3 is provided between two adjacent resonators 2; a cross-coupling device 4 is provided between non-adjacent resonators 2, and the cross-coupling device 4 is Used to connect the transmission line at the bottom of the non-adjacent resonator 2, the transmission line can be a coaxial line, a microstrip line or a strip line, the contact surface between the transmission line and the bottom 2 of the resonator is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com