Integrated automation transformer substation

A comprehensive automation and substation technology, applied in the direction of panel/switch station circuit devices, busbar/line layout, etc., can solve problems such as hidden safety hazards, poor reliability, and backward functions, so as to improve equipment operation reliability and improve sustainable competitiveness. , the effect of improving the level of intelligence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

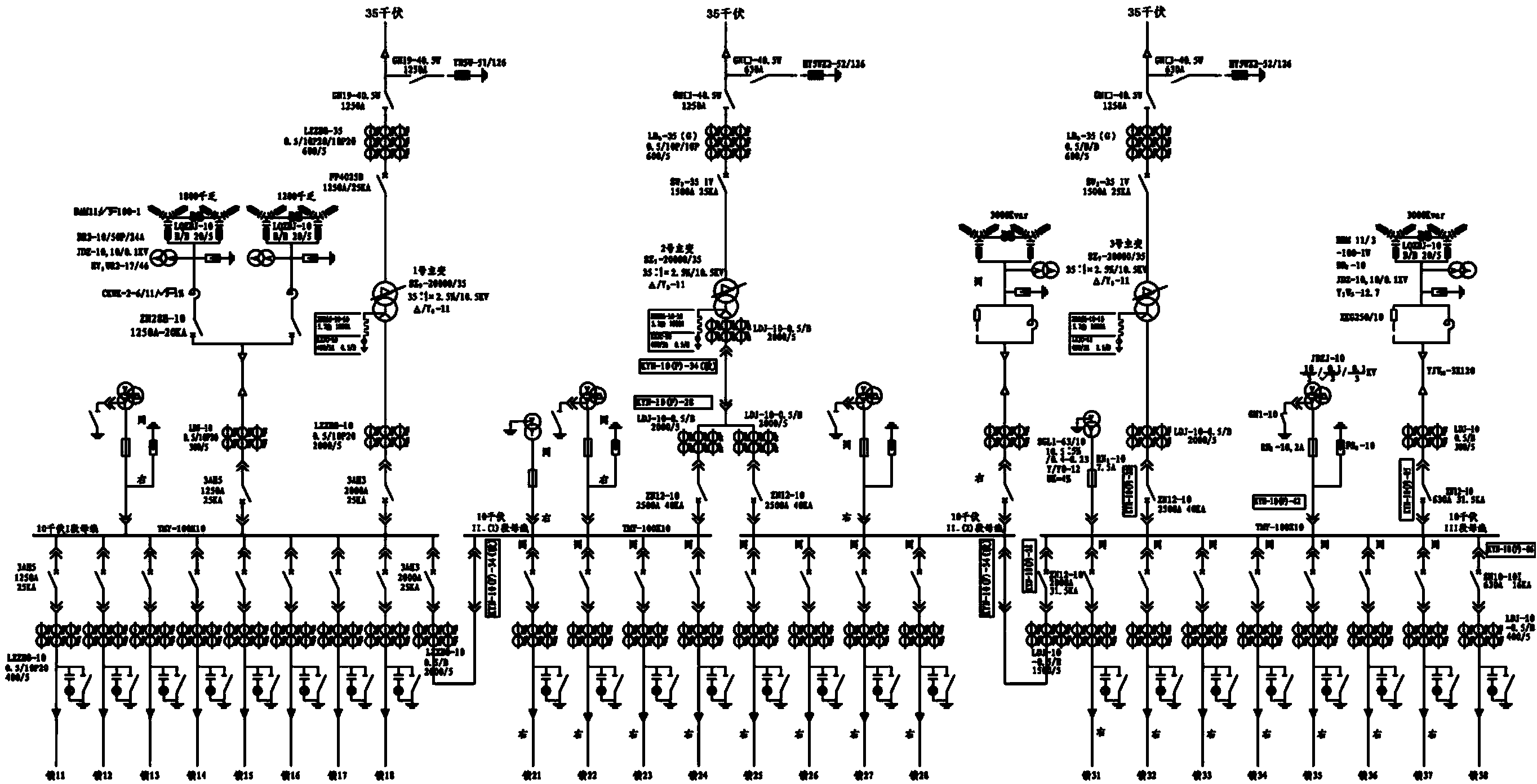

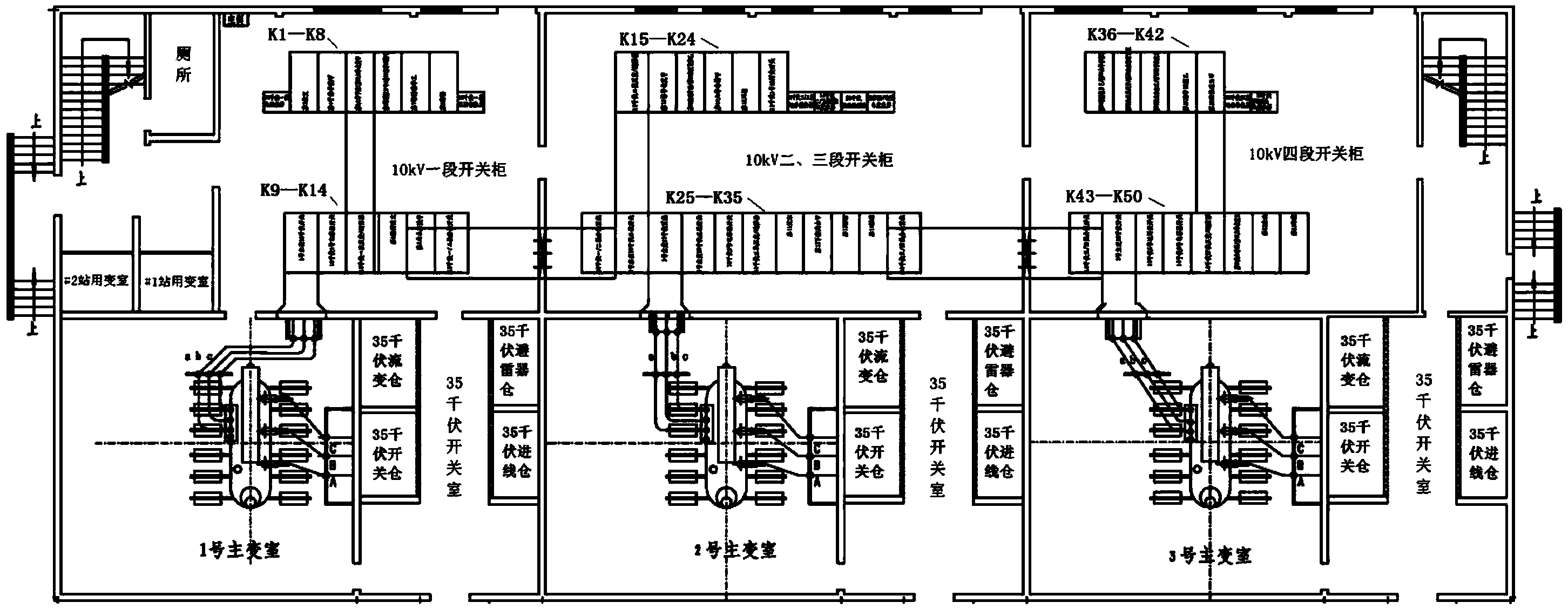

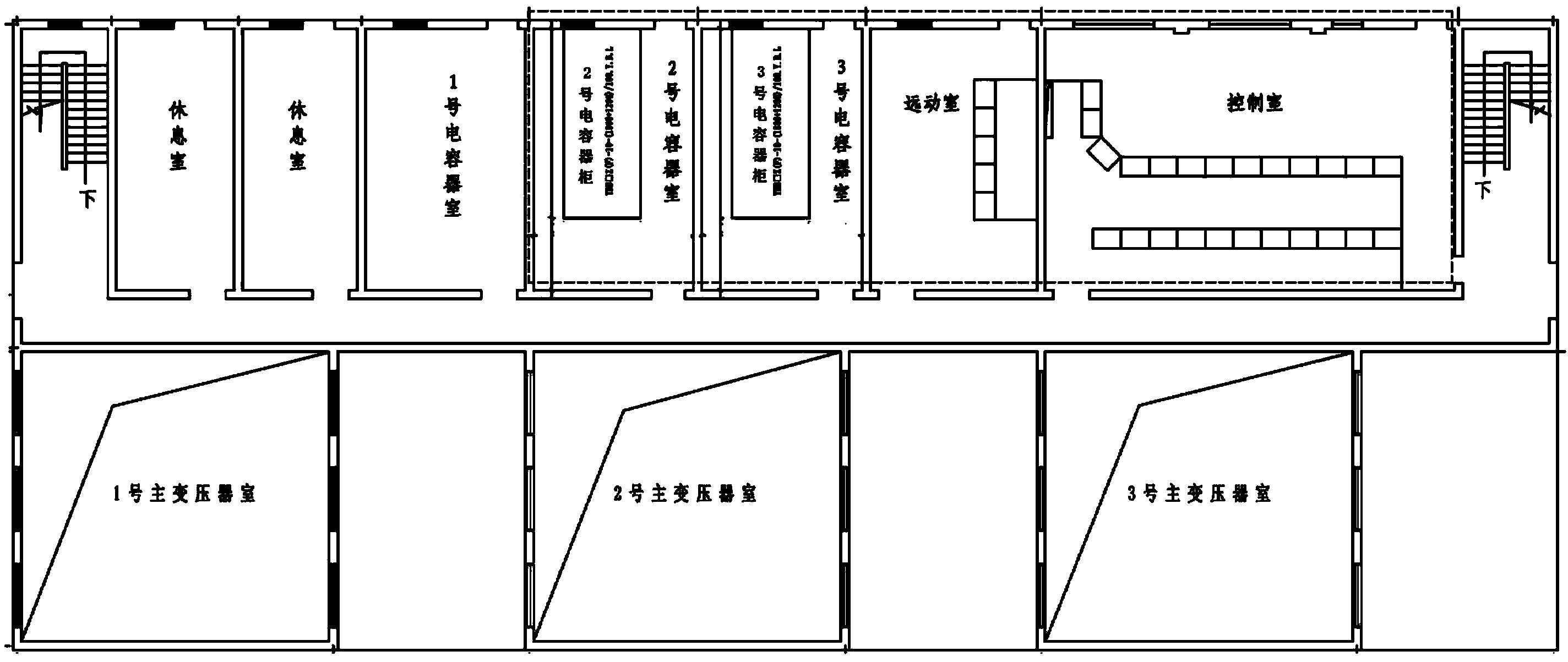

[0035] like Figure 5 , Figure 5A As shown, the present invention provides a comprehensive automatic substation, which adopts the wiring mode of line transformer group. The first 35kV incoming line supplies power to No. 1 main transformer, a 10kV busbar and its eight outgoing lines; the second 35kV incoming line is No. 2 main transformer. Transformer, 10kV two-section busbar and its four outgoing lines and three-section busbar and its four outgoing lines supply power; the third 35kV incoming line supplies power to No. 3 main transformer, 10kV four-section busbar and its eight outgoing lines.

[0036]Three 35kV incoming line switches Q1 are installed in the 35kV / 10kV switch room, using SF6 circuit breakers and equipped with spring operating mechanisms to connect or disconnect the corresponding 35kV power incoming lines. Each 35kV incoming line is connected to each 35kV incoming line switch Q1 through the corresponding 35kV current transformer, and a 35kV incoming line arreste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com