Valve train for an internal combustion engine

A transmission device and internal combustion engine technology, applied in the direction of valve devices, machines/engines, mechanical equipment, etc., can solve the problems of high design costs, high control technology costs, etc., and achieve the effects of low calculation costs, reduced adjustment costs, and reduced design costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

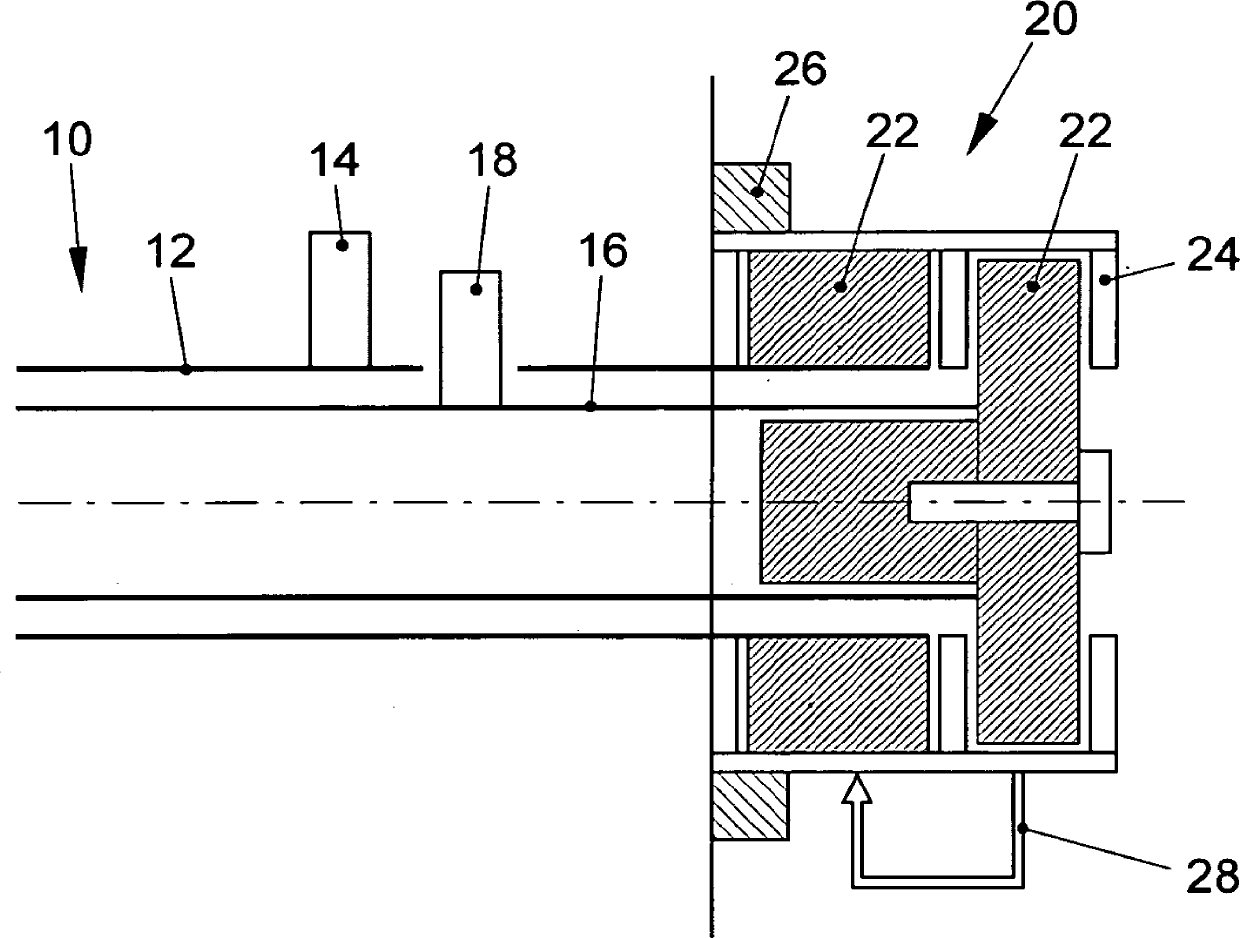

[0025] figure 1 The main components of the valve train according to the invention are shown in a schematic diagram. It includes a camshaft 10 which is designed as a double, hybrid camshaft. To this end, the camshaft includes an outer shaft 12 with a plurality of cams 14 distributed over its length, which are provided for actuating exhaust valves of an internal combustion engine. An inner shaft 16 is rotatably mounted within the outer shaft 12 . Also arranged on the outer side of the inner shaft 16 are a plurality of cams 18 distributed over its length, which serve to control the intake valves of the internal combustion engine.

[0026] The camshaft 10 is connected with one end to a phase adjuster 20 . The phase adjuster comprises two actuators, wherein a first actuator is non-rotatably connected to the inner shaft 16 of the camshaft 10 and a second actuator is non-rotatably connected to the outer shaft 12. rotationally connected. The actuator has a rotor 22 with adjusting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com