A device and method for evaluating sand-carrying effect of fracturing fluid

A technology for evaluating equipment and fracturing fluid, which is applied in the field of fracturing, and can solve the problems of not having a horizontal well fracture model, not considering the impact of fracturing fluid sand-carrying effect, and affecting evaluation results, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention will be further described in detail below in conjunction with specific embodiments, which are explanations of the present invention rather than limitations.

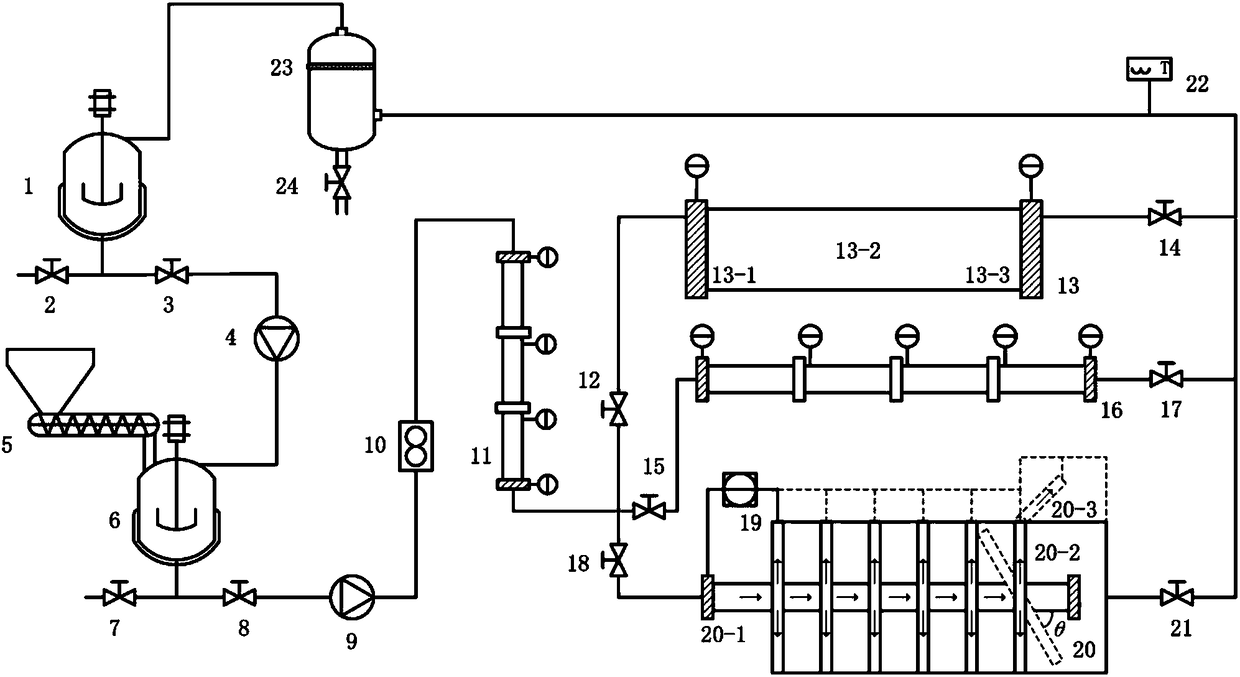

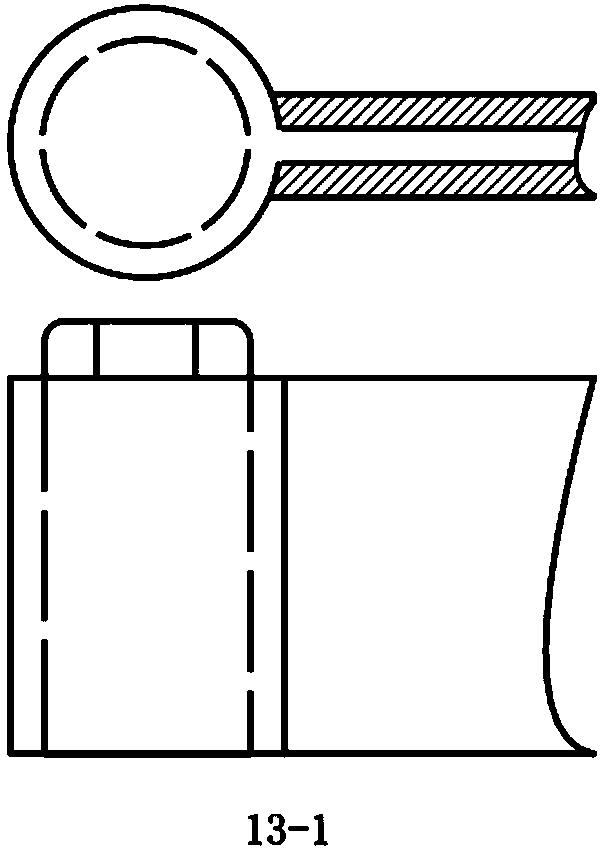

[0049] Such as figure 1 As shown, a fracturing fluid sand-carrying effect evaluation device includes: a fracturing fluid tank 1, the outlet of which is connected with a first screw pump 4, a sand mixing tank 6, a second screw pump 9, an electromagnetic flowmeter 10 and Vertical shaft 11 entrance;

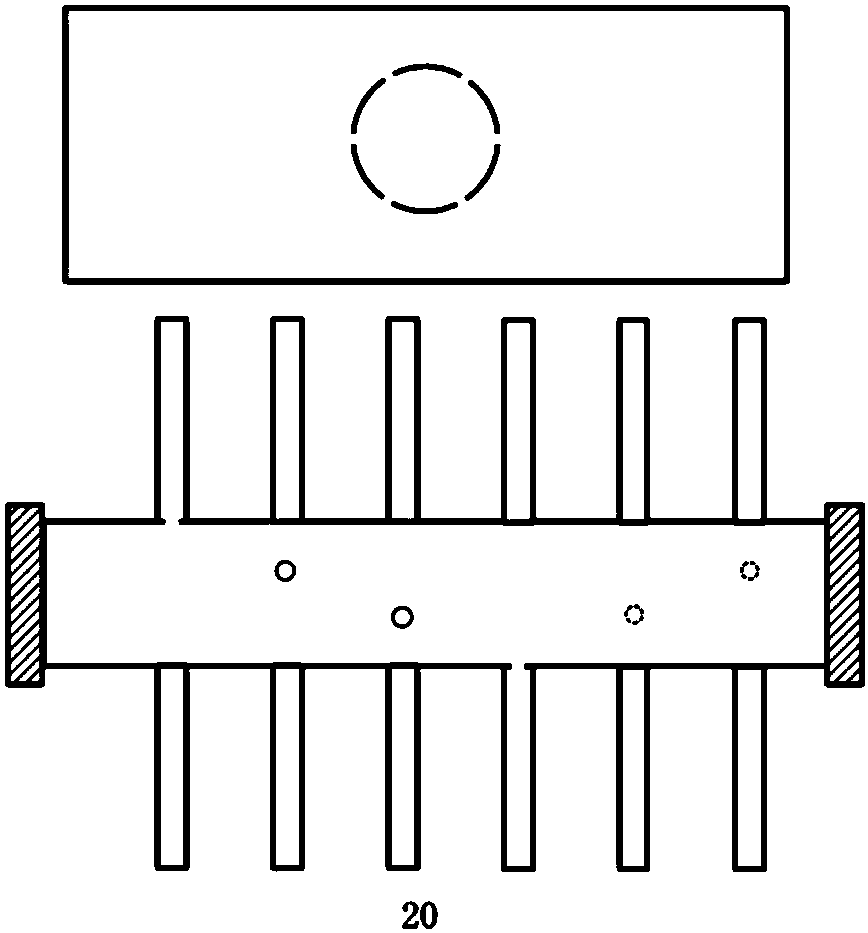

[0050]Among them, a sand adding device 5 is installed at the entrance above the sand mixing tank 6, and the outlet of the vertical shaft 11 is connected to three branches at the same time. The two branches are sequentially connected to the seventh valve 15, the first horizontal wellbore 16 and the eighth valve 17, and the third branch is connected to the ninth valve 18, the horizontal well fracture model 20 and the tenth valve 21 in sequence. After the three branches meet The temperature sensor 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com