Machine body process temperature measuring device in screw extrusion molding process of screw extrusion propellant material

A molding process and measuring device technology, applied in the direction of measuring devices, adopting mechanical devices, analyzing materials, etc., can solve problems such as combustion, explosion, frictional heating, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

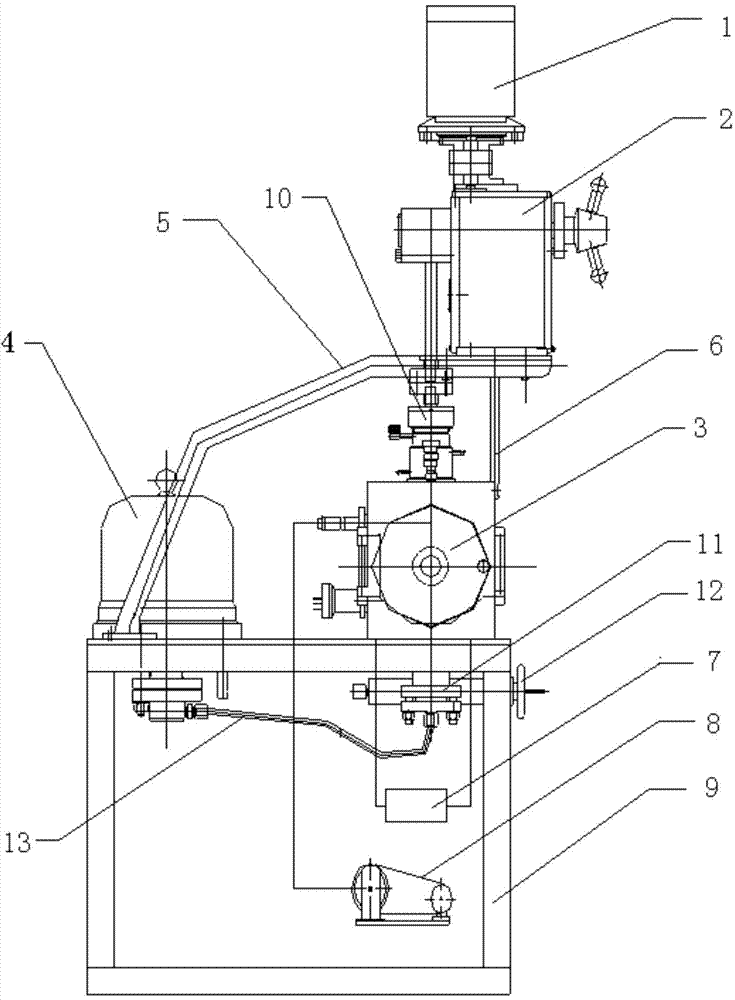

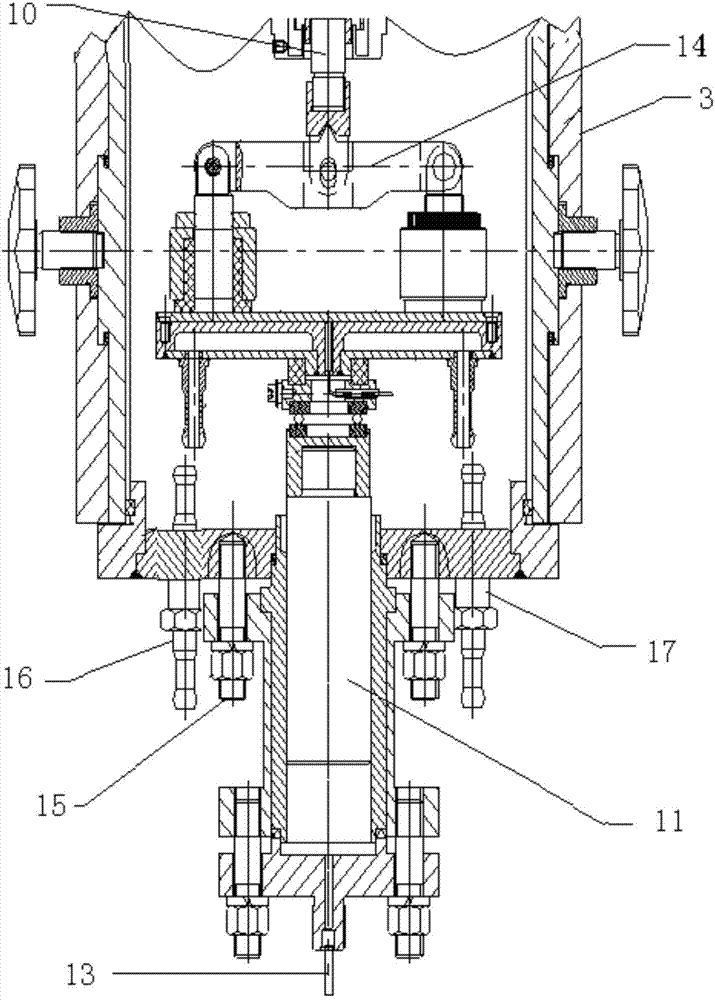

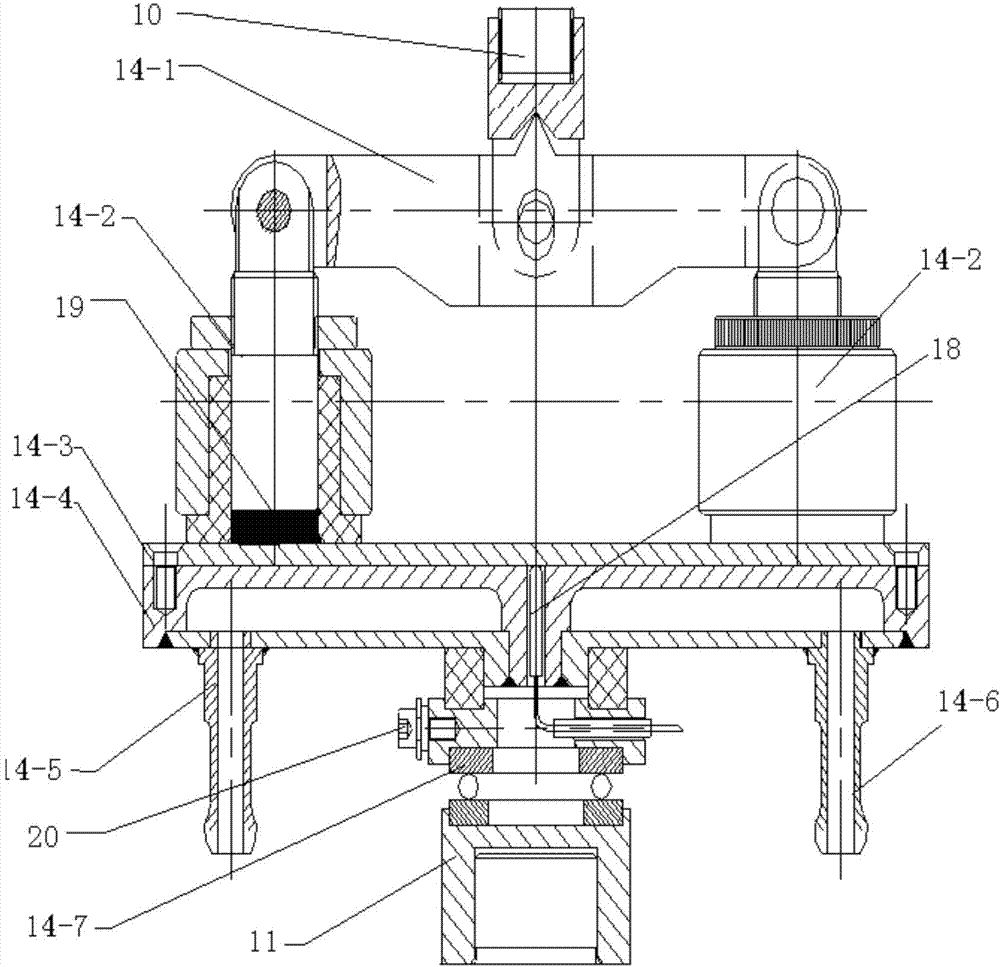

[0023] Such as figure 1 , figure 2 As shown, the measuring device of the screw press propellant material screw press forming process temperature of the present invention includes a motor 1, a gearbox 2, a test box 3, a hydraulic pump 4, a bracket 5, a pillar 6, a constant temperature water tank 7, a vacuum pump 8, Underframe 9, rotating shaft 10, hydraulic cylinder 11, fixed frame 12, hydraulic oil pipe 13, friction meter 14, water inlet pipe 16, water outlet pipe 17, temperature sensor 18 and computer; wherein:

[0024] The bottom frame 9 is a truss; the test box 3, the hydraulic pump 4, the constant temperature water tank 7 and the vacuum pump 8 are all installed on the bottom frame 9; the gearbox 2 is installed on the bottom frame 9 through the bracket 5 and is located above the test box 3, A vertical pillar 6 is also supported between the gearbox 2 and the test box 3 to further stabilize the gearbox 2; the motor 1 is fixed above the gearbox 2 and connected to the gearbox...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com