Adhesive force testing device and adhesive force testing method thereof

A technology for testing devices and adhesion, applied in the direction of measuring devices, mechanical devices, instruments, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with accompanying drawing.

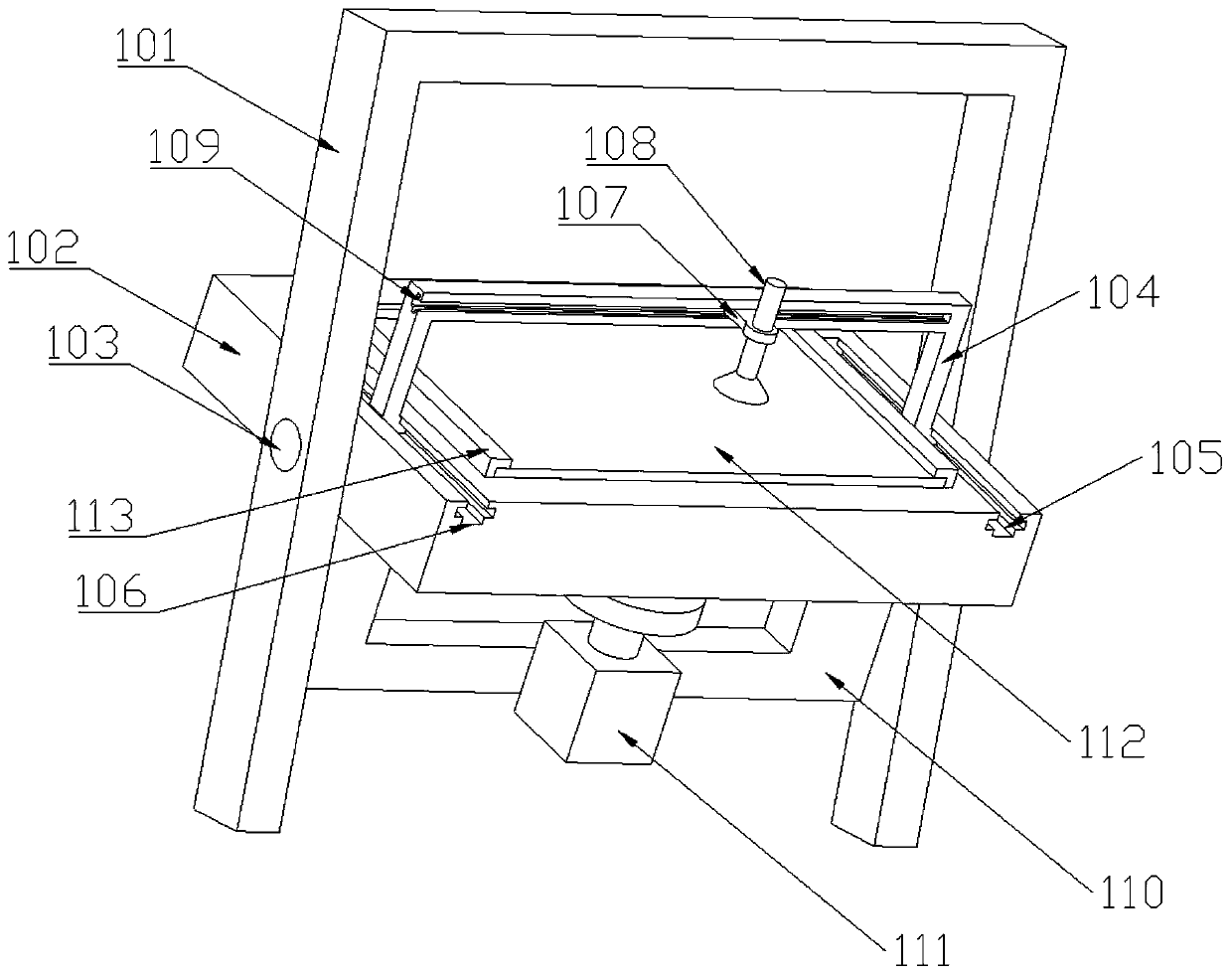

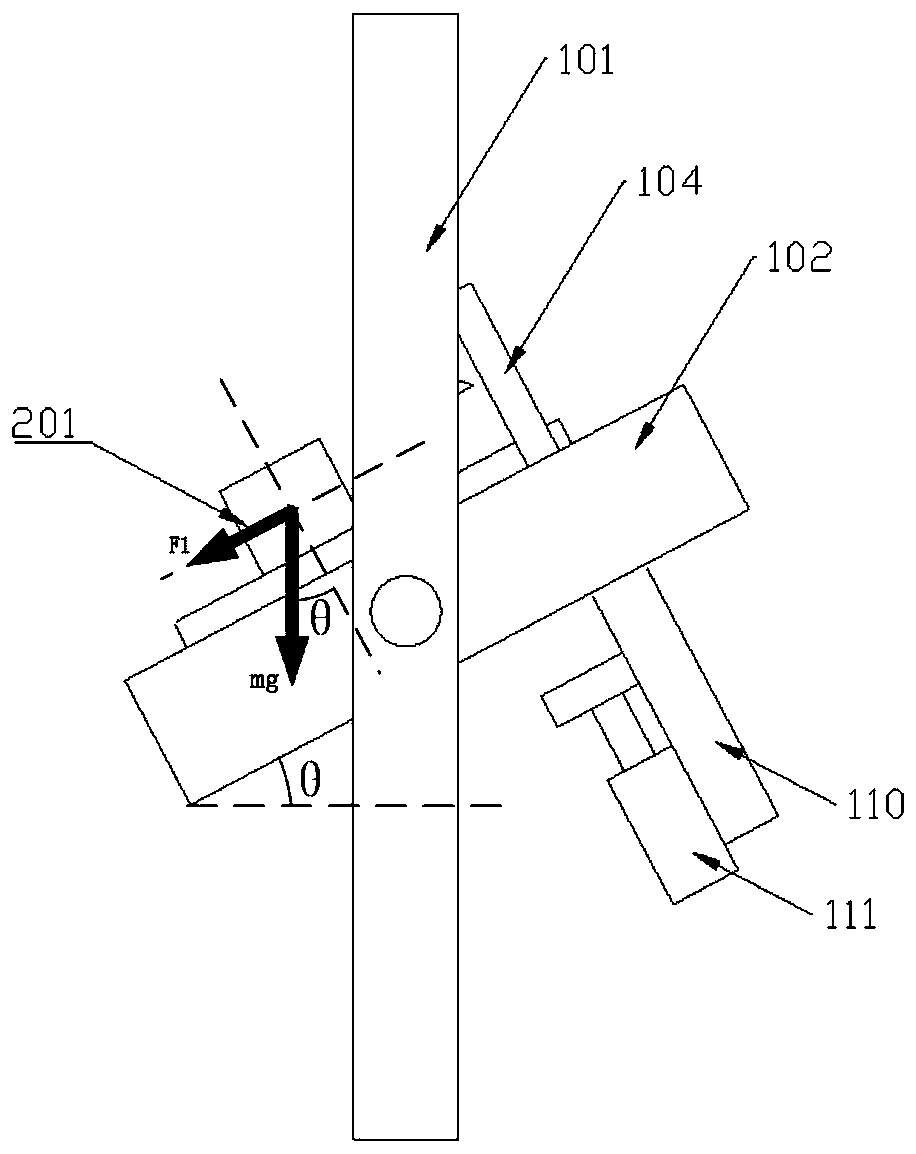

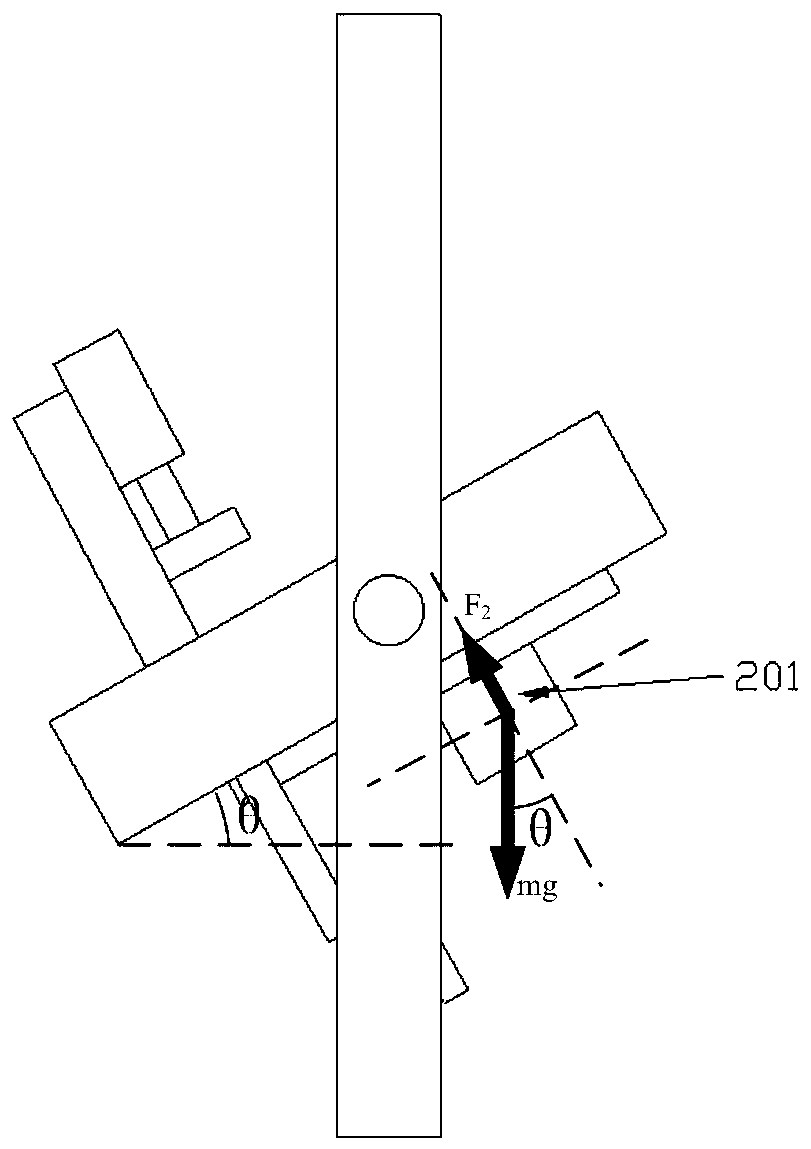

[0036] Such as figure 1 As shown, a kind of adhesion testing device comprises test bench support 101, turning platform 102, motor, angle sensor, rotating shaft 103, slide table 104, slide block 107, slide bar 108, camera support 110, camera 111, substrate 112, substrate fixing bar 113 and controller. A horizontally arranged rotational axis 103 is supported on the test bench support 101 . The turning platform 102 is fixed to the rotating shaft 103 . The motor is fixed on the test bench support 101 , and the output shaft is fixed to one end of the rotating shaft 103 . The rotation and locking of the turning platform 102 are realized by controlling the motor. The motor adopts a double output shaft motor.

[0037] The angle sensor is fixed to the motor, and the input shaft is fixed to the output shaft of the motor. The angle sensor adopts an absolute encoder, which can de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com