Automatic edible mushroom stick bagging bagging machine

An edible fungus, fully automatic technology, applied in the fields of application, horticulture, botanical equipment and methods, etc., can solve the problems of weak strength, slow feeding speed, unapplicable bagging and fixing bag methods, etc., to achieve fast bagging Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with accompanying drawing:

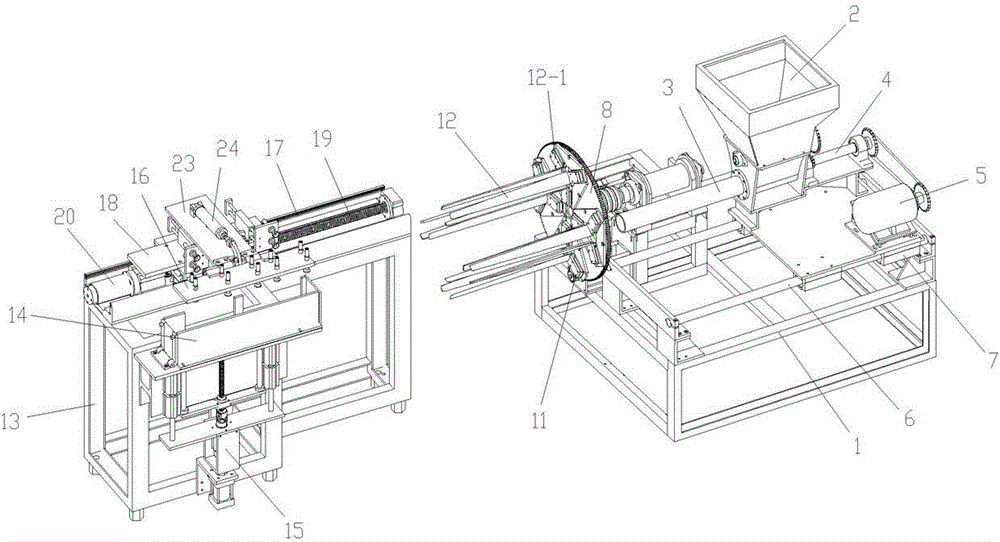

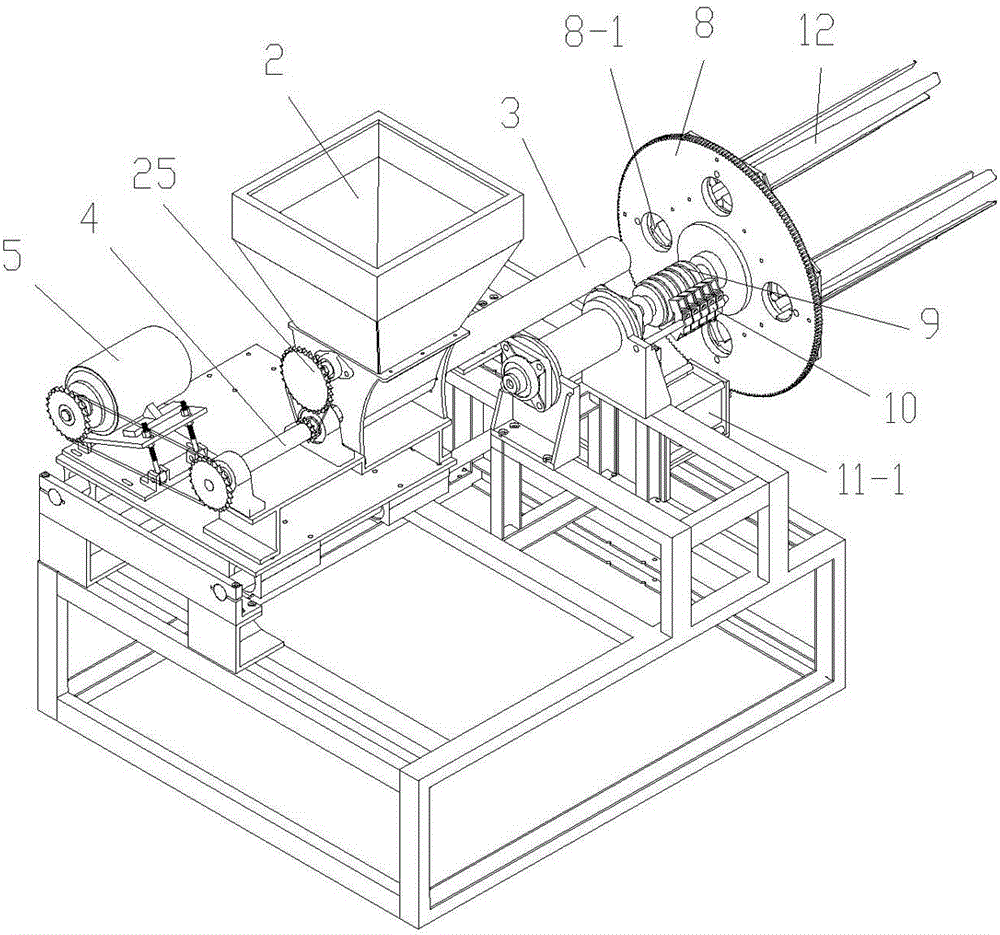

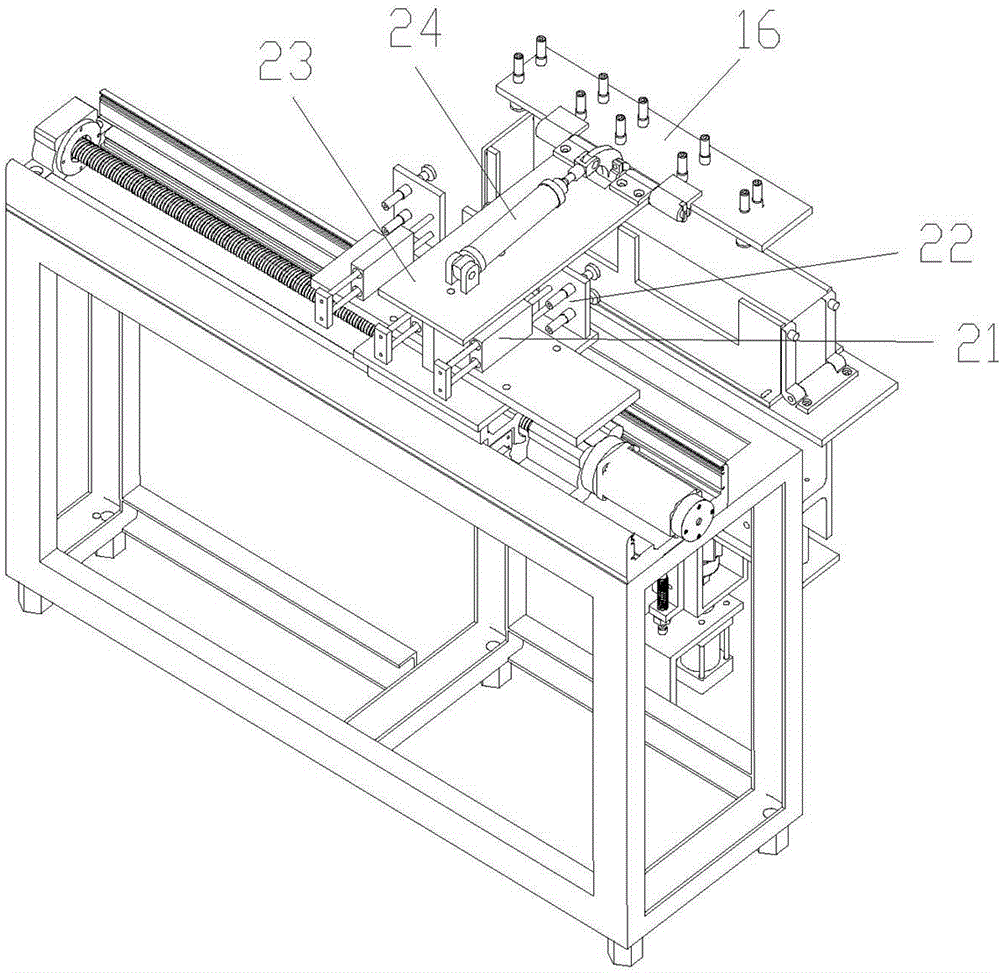

[0015] Referring to the accompanying drawings: this fully automatic edible mushroom stick bagging bagging machine includes a frame 1, a hopper 2 is arranged on the frame 1, and a discharge pipe 3 arranged horizontally and horizontally is provided at the lower end of the hopper 2, and the discharge pipe 3 3 is provided with a delivery rod 4, the delivery rod 4 is connected to the drive motor 5, the hopper 2 is installed on the horizontal slide rail 6, the horizontal slide rail 6 is fixed on the frame 1, and the push-pull cylinder for the hopper 2 to slide is installed on the frame 1 7; where the right end of the frame 1 is provided with a turntable 8, the turntable 8 is provided with a group of through holes 8-1 for the discharge pipe 3 to pass through at intervals, the turntable 8 is installed on the frame 1 through the rotating shaft 9, and the rotating shaft 9 is equipped ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com