A method of using alkynes to synthesize palladium catalysts

A technology of alkyne compounds and palladium catalysts, which is applied in the field of palladium catalyst synthesis, and can solve the problems of low yield, high cost, and many synthesis steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

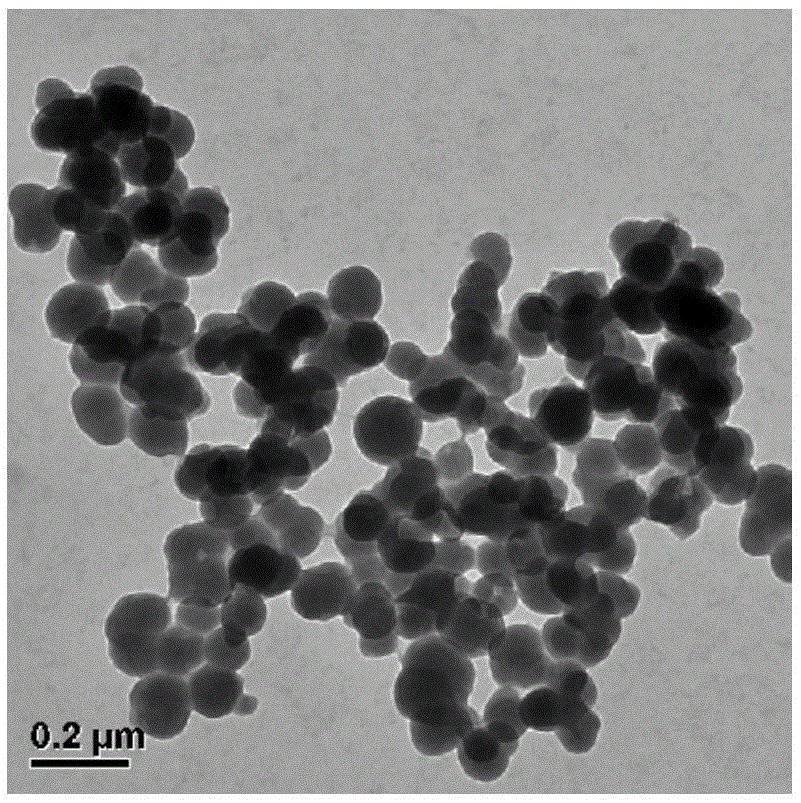

[0028] Firstly, 15 mL of 20 mM chloropalladium acid aqueous solution was prepared according to the literature method. The solution was transferred to a pressure-resistant glass container and stirred at room temperature. Afterwards, 0.3 atm acetylene gas was introduced and the reaction was continued for 15 min at room temperature. After the reaction, the solution was centrifuged and the supernatant was removed. Then, the obtained solid matter was washed twice each with ethanol and water. Afterwards, a reddish-brown powder was obtained after vacuum drying.

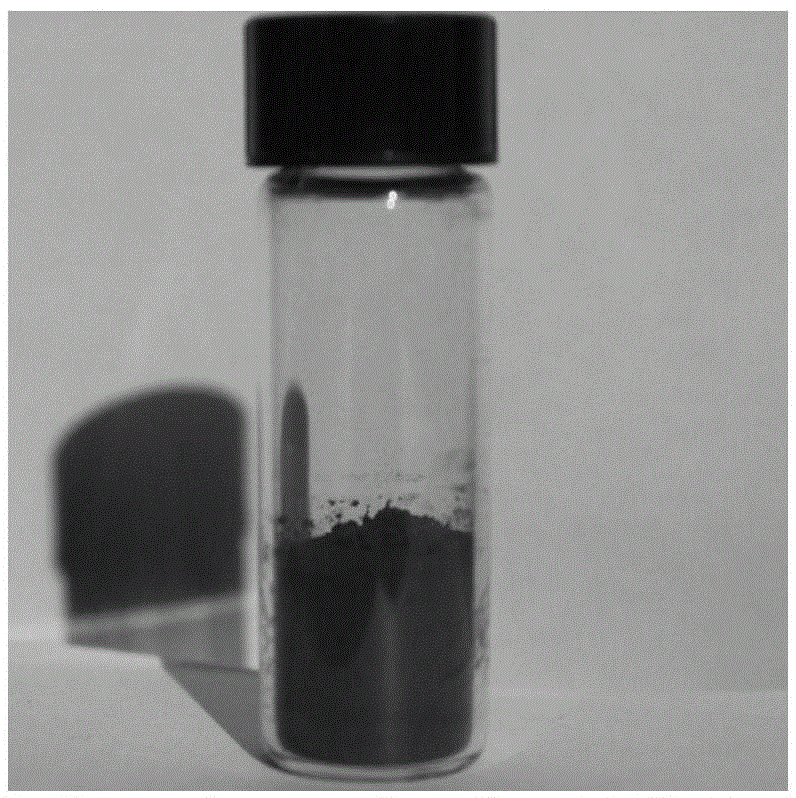

[0029] figure 1 After passing 0.3atm acetylene gas into 20mM chloropalladium acid aqueous solution, the originally clear solution immediately became turbid, which proved that acetylene and Pd(II) reacted rapidly.

[0030] figure 2 for from figure 1 About 1g of reddish-brown powder isolated in the container, the powder can be stored at room temperature and exposed to air for at least 6 months without significant change...

Embodiment 2

[0042] Firstly, 15 mL of 20 mM chloropalladium acid aqueous solution was prepared according to the literature method. The solution was transferred to a pressure-resistant glass container, and 640 mg of activated carbon was added. After fully stirring for 30 min, 0.3 atm acetylene gas was introduced and allowed to continue to react at room temperature for 15 min. After the reaction, the solution was centrifuged and the supernatant was removed. Then, the obtained solid matter was washed twice each with ethanol and water. The product was vacuum-dried to obtain a black powder, that is, activated carbon-supported Pd catalyst.

Embodiment 3

[0044] Firstly, 15 mL of 20 mM chloropalladium acid aqueous solution was prepared according to the literature method. The solution was transferred to a pressure-resistant glass container and stirred at room temperature. Afterwards, 0.3 atm propyne gas was introduced and the reaction was continued for 15 min at room temperature. After the reaction, the solution was centrifuged and the supernatant was removed. Then, the obtained solid matter was washed twice each with ethanol and water. Afterwards, the product was vacuum-dried to obtain a brown-black powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com