Membrane surface treatment method and device

A processing method and technology for the surface of the film, which can be applied in the directions of spraying devices, liquid spraying devices, instruments, etc., and can solve the problems of poor adhesion of TAC films.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0123] Examples are described, but the present invention is not limited to the following examples.

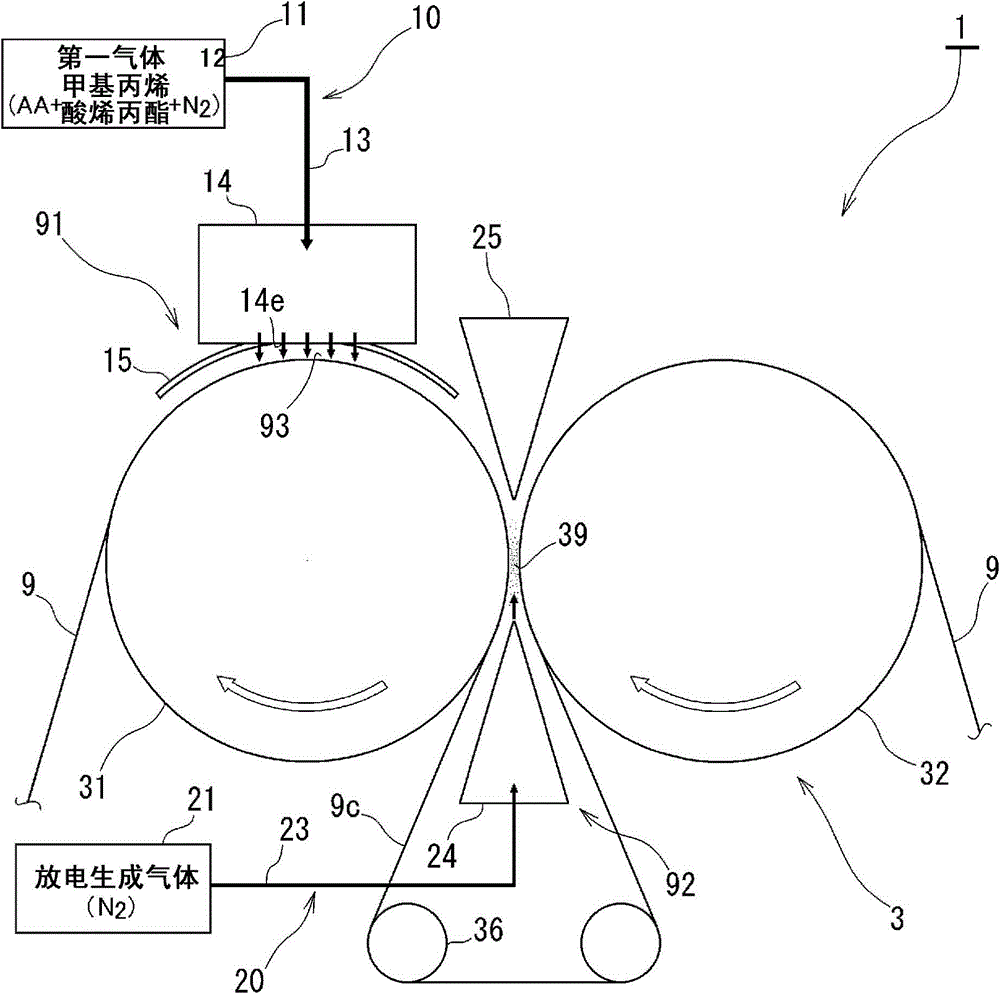

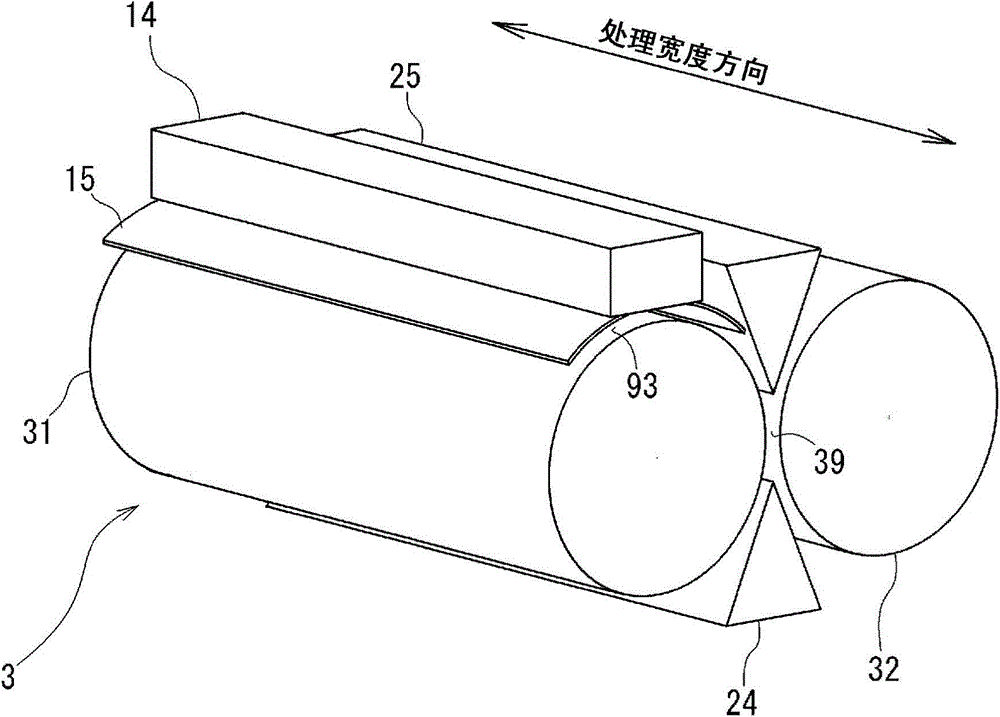

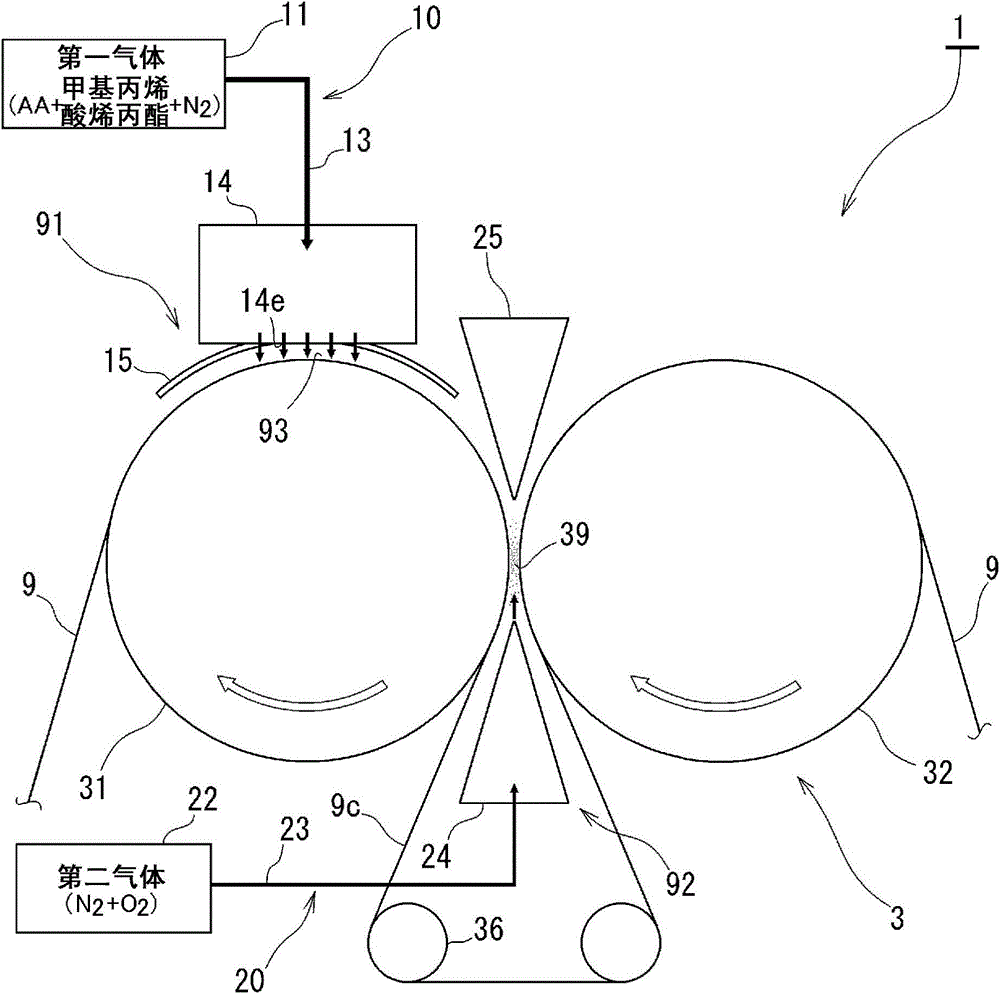

[0124] The surface treatment of the film 9 was performed using the film surface treatment apparatus 1 shown in FIG. 1 .

[0125] The dimensional structure of the device 1 is as follows.

[0126] Axial length in the processing width direction of the rollers 31, 32: 390mm

[0127] Diameter of rollers 31, 32: 320mm

[0128] Blowout width in the treatment width direction of nozzles 14, 24: 300mm

[0129] The circumference of the arc direction of the first processing space 93: 275mm

[0130]Thickness of the first processing space 93: 5mm

[0131] Thickness of the narrowest part of the discharge gap 39: 1mm

[0132] As the film 9 to be processed, a TAC film was used. The width of the TAC film 9 is 325 mm.

[0133] The conveying speed of the TAC film 9 was 2.5 m / min.

[0134] The temperature of the rollers 31 and 32 and the temperature of the TAC film 9 were set to 35°C.

[0...

Embodiment 2

[0156] In Example 2, in the apparatus 1 of FIG. 1 , the flow rate of each component of the first gas in the first treatment step is as follows.

[0157] Carrier gas (N 2 )30slm

[0158] Acrylic acid 3g / min

[0159] Allyl methacrylate 0.3g / min

[0160] Therefore, the content rate of the allyl methacrylate in the 1st gas with respect to acrylic acid was 10 wt%. Other processing conditions were the same as in Example 1. The preparation procedure of the surface-treated polarizing plate sample, and the contents of the adhesive strength evaluation and the hot water resistance evaluation were also the same as in Example 1. As a result of the adhesive strength evaluation, adhesive strength=8.8 N / inch. As a result of the hot water resistance evaluation, color leakage width=0.89 mm. Peeling was not confirmed between the treated TAC film 9 and the PVA film. Therefore, both adhesive strength and hot water resistance are favorable.

Embodiment 3

[0162] In Example 3, in the apparatus 1 of FIG. 1 , the flow rate of each component of the first gas in the first treatment step is as follows.

[0163] Carrier gas (N 2 )30slm

[0164] Acrylic acid 3g / min

[0165] Allyl methacrylate 0.03g / min

[0166] Therefore, the content rate of the allyl methacrylate in the 1st gas with respect to acrylic acid was 1 wt%. Other processing conditions were the same as in Example 1. The preparation procedure of the surface-treated polarizing plate sample, and the contents of the adhesive strength evaluation and the hot water resistance evaluation were also the same as in Example 1. As a result of the adhesive strength evaluation, adhesive strength=9.2 N / inch. As a result of the hot water resistance evaluation, color leakage width=0.95 mm. Peeling was not confirmed between the treated TAC film 9 and the PVA film. Therefore, both adhesive strength and hot water resistance are favorable.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com