Cleaning device of slitting rewinding machine

A cleaning device, slitting and rewinding technology, applied to the cleaning method using tools, the cleaning method using gas flow, cleaning methods and utensils, etc., can solve the problem of inability to eliminate dust and impurities, easy to occupy dust or other impurities, Electronic die-cutting manufacturers have troubles and other problems, and achieve the effect of simple structure, reasonable setting and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings.

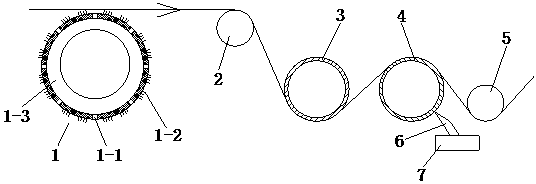

[0017] Such as figure 1 As shown, a cleaning device for a slitter rewinder according to the present invention includes a cleaning roller 1, a drying roller 3 and a dust-sticking wheel 4, and the drying roller 3 is arranged between the cleaning roller 1 and the dust-sticking wheel 4;

[0018] The cleaning roller 1 is provided with several dust suction holes 1-1 on the circumference, and the two sides of the dust suction holes 1-1 are respectively provided with brushes 1-2, and the dust suction holes 1-1 and the negative pressure chamber 1 of the cleaning roller 1 -3 are connected to each other, and the negative pressure chamber 1-3 is connected to the negative pressure air pipe;

[0019] A water-absorbing cotton layer is attached to the outer surface of the drying roller 3; a colloidal layer for dust removal and static electricity is attached to the surface of the stic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com