Material transfer device

A transfer device and material technology, which is applied in metal processing and other directions, can solve the problem that the shearing machine cannot be aligned with the material, and achieve the effect of convenient processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The material transfer device in the present invention will be described in further detail below in conjunction with the accompanying drawings.

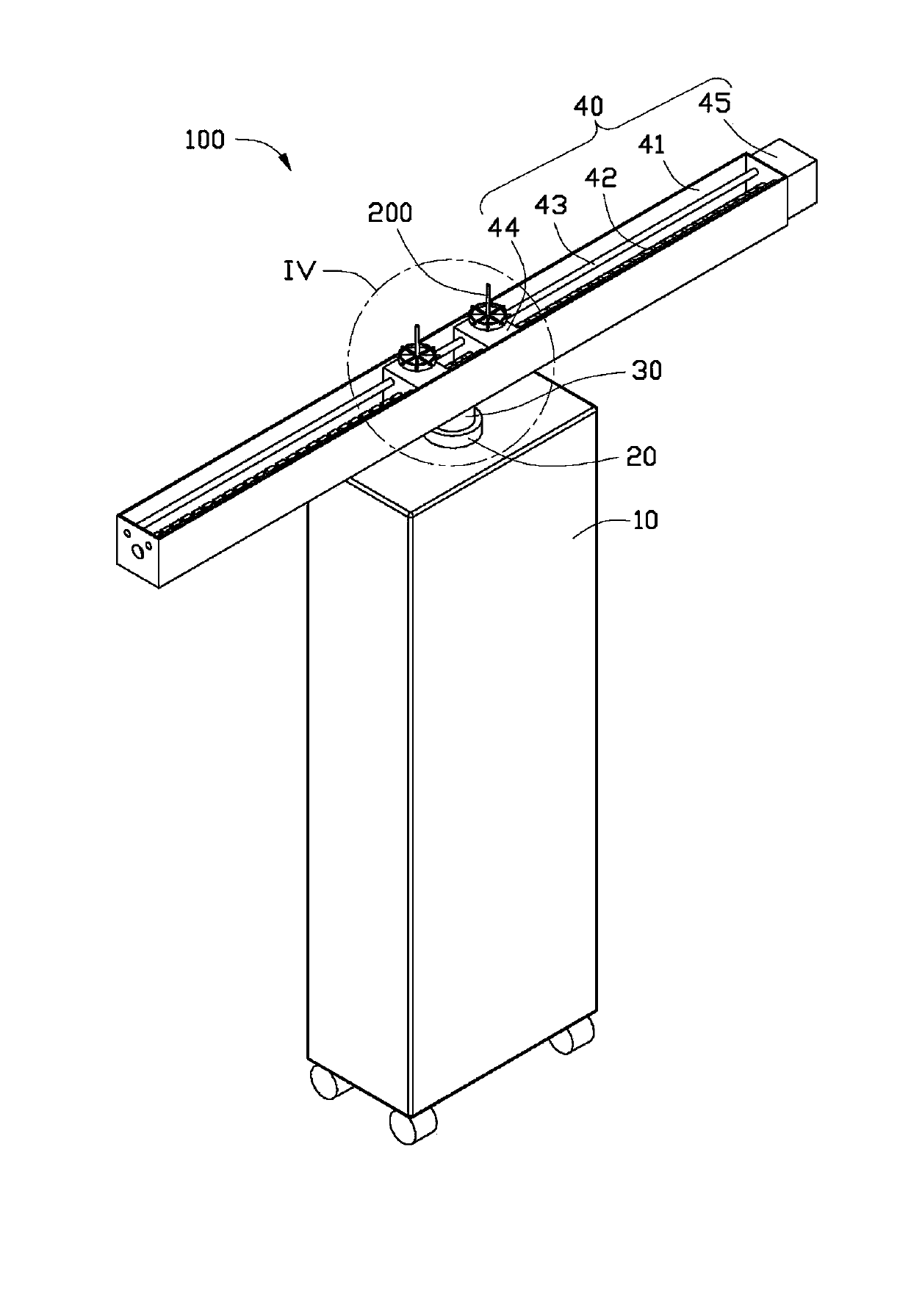

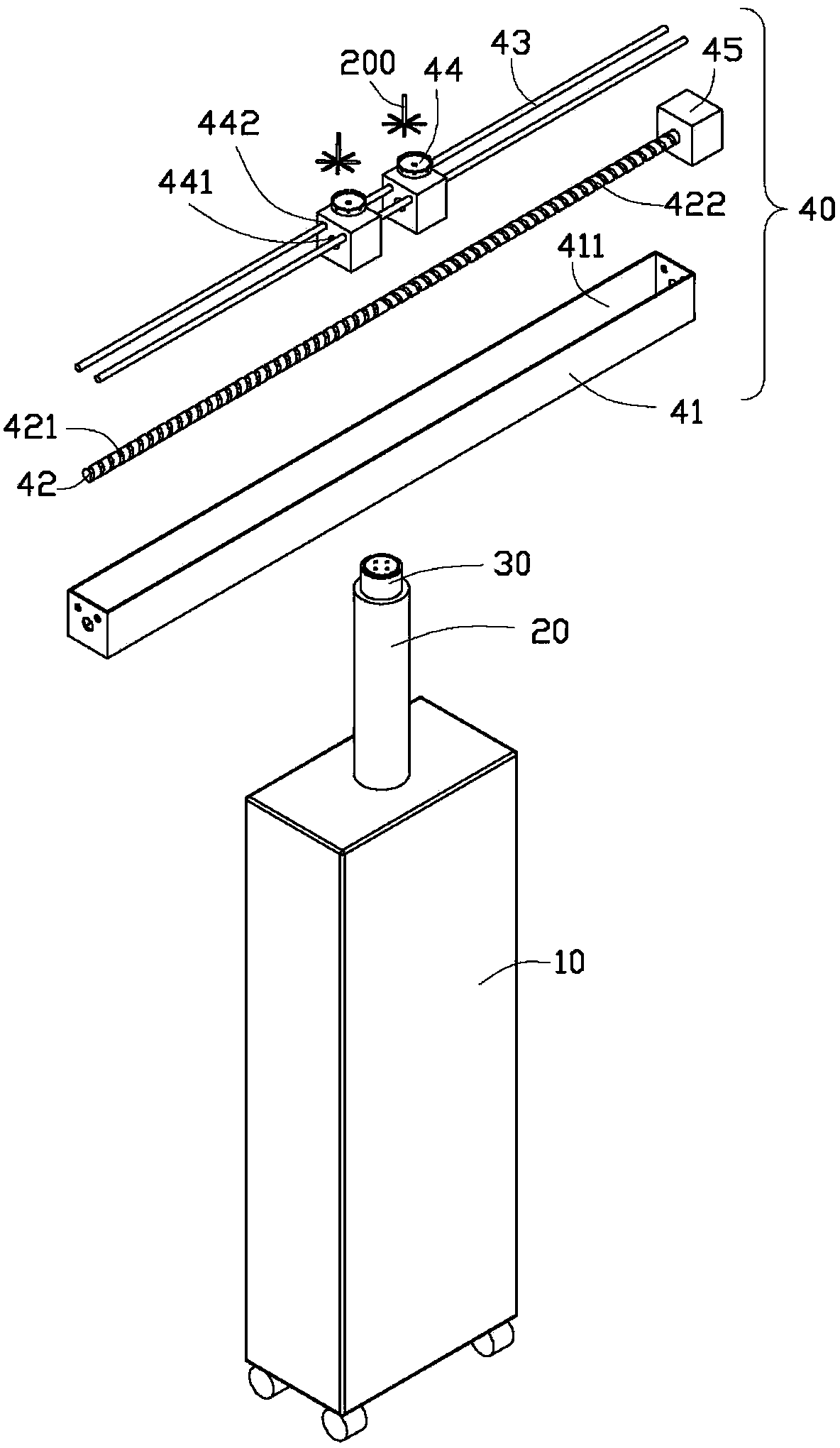

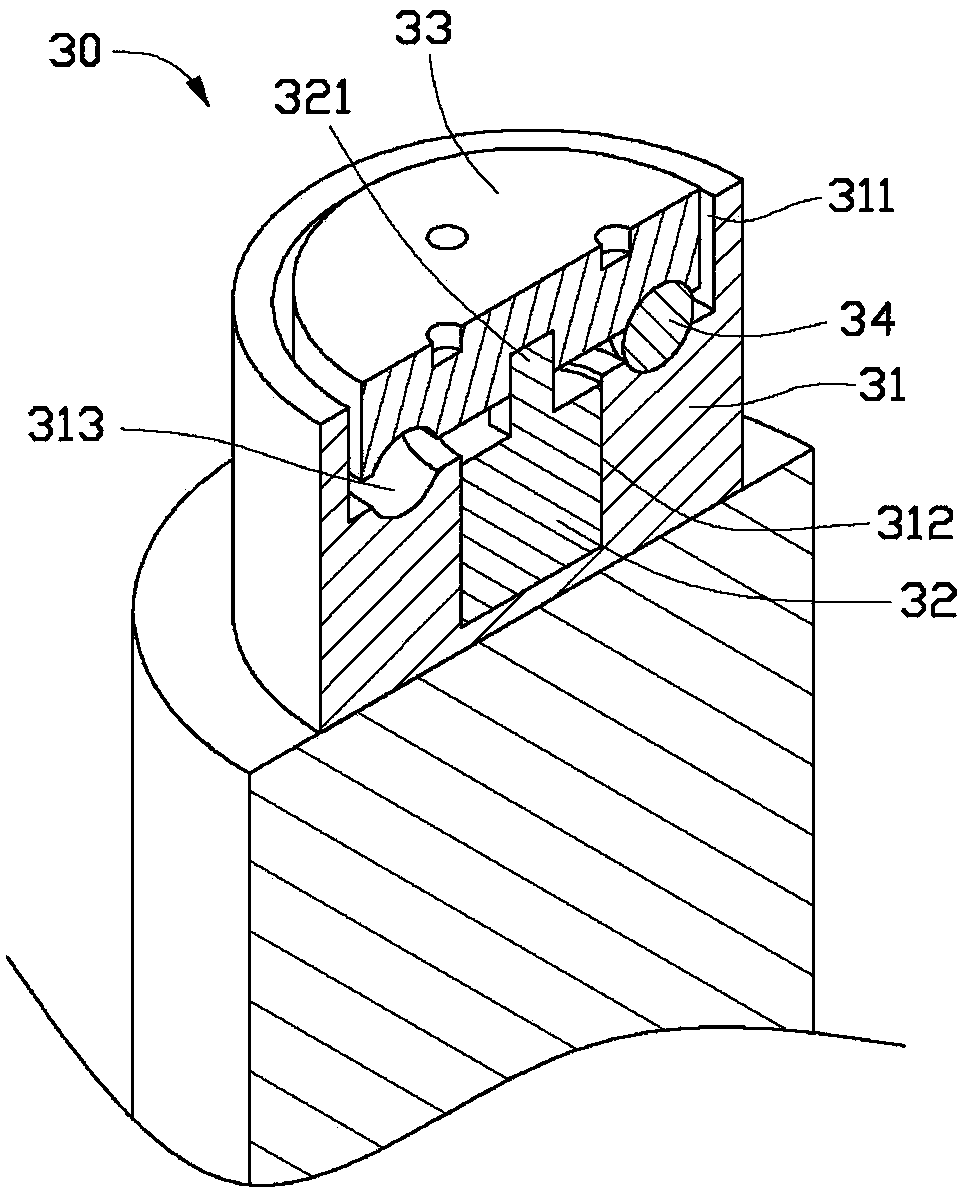

[0015] Please refer to figure 1 and figure 2 , in a preferred embodiment of the present invention, the material transfer device 100 is used to transfer the material produced by the forming machine to the shearing machine for shearing. The material transfer device 100 includes a base 10 , a support rod 20 , a rotating part 30 and a transfer mechanism 40 . The transfer mechanism 40 is rotatably connected to the top of the base 10 through the support rod 20 and the rotating part 30, and rotates under the drive of the rotating part 30, thereby transporting the materials placed on the transfer mechanism 40 to the shear The location of the cutting machine.

[0016] The base 10 is a cuboid structure, and the support rod 20 is telescopically arranged on the top of the base 10, which is pushed by a driving mechanism (such as a cylin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com