A vehicle simulator

A driver and vehicle technology, applied in the field of vehicles and vehicle simulation drivers, can solve problems such as high maintenance costs, unsuitable for simple and cheap test principles, complex system control, etc., and achieve the effect of facilitating steering stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

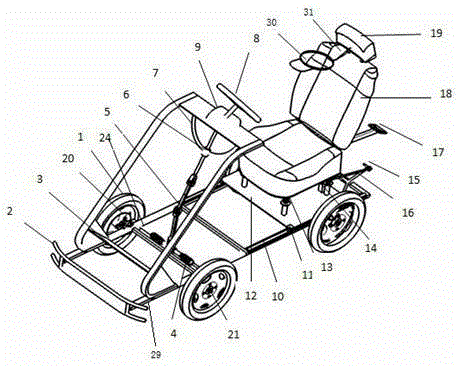

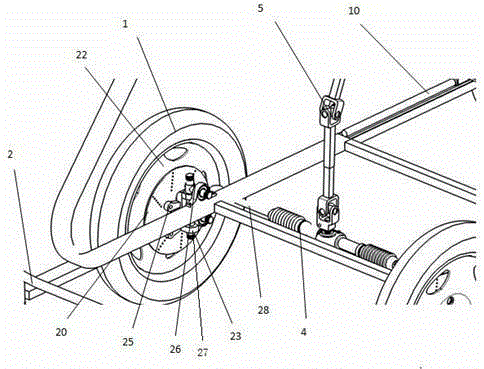

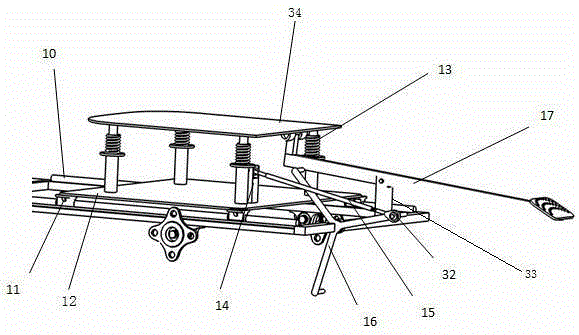

[0027] Embodiment 1: if Figures 1 to 6As shown, the driver of this embodiment includes a front wheel steering system, and also includes a seat system with vibration and motion functions. The seat system with vibration and motion functions includes an elastic device and a bump pedal 17. The elastic device is on the upper A spring push column 14 is installed between the bracket 34 and the lower bracket, the seat is installed on the upper bracket 34, the up and down bump pedal 17 is hinged on the frame through the rear column 33, and one end of the up and down bump pedal 17 is fixed on the upper bracket through a bearing The lower surface of 34; the seat system with vibration and motion function also includes a sliding rail device and a triangular turning plate 16. The sliding rail device is a seat through the slider 11 to install the lower bracket 12 on the sliding rail 10 of the frame, and the triangular rotation The disc 16 is composed of three sides that meet at one point an...

Embodiment approach 2

[0028] Embodiment 2: as Figures 1 to 6 As shown, the driver of this embodiment includes a front wheel steering system, and also includes a seat system with vibration and motion functions. The seat system with vibration and motion functions includes an elastic device and a bump pedal 17. The elastic device is on the upper A spring push column 14 is installed between the bracket 34 and the lower bracket, the seat is installed on the upper bracket 34, the up and down bump pedal 17 is hinged on the frame through the rear column 33, and one end of the up and down bump pedal 17 is fixed on the upper bracket through a bearing The lower surface of 34; the seat system with vibration and motion function also includes a sliding rail device and a triangular turning plate 16. The sliding rail device is a seat through the slider 11 to install the lower bracket 12 on the sliding rail 10 of the frame, and the triangular rotation The disc 16 is composed of three sides that meet at one point a...

Embodiment approach 3

[0029] The third embodiment is as Figures 1 to 6 As shown, the driver of this embodiment includes a front wheel steering system, and also includes a seat system with vibration and motion functions. The seat system with vibration and motion functions includes an elastic device and a bump pedal 17. The elastic device is on the upper A spring push column 14 is installed between the bracket 34 and the lower bracket, the seat is installed on the upper bracket 34, the up and down bump pedal 17 is hinged on the frame through the rear column 33, and one end of the up and down bump pedal 17 is fixed on the upper bracket through a bearing The lower surface of 34; the seat system with vibration and motion function also includes a sliding rail device and a triangular turning plate 16. The sliding rail device is a seat through the slider 11 to install the lower bracket 12 on the sliding rail 10 of the frame, and the triangular rotation The disc 16 is composed of three sides that meet at o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com