A kind of automatic concrete curing system and curing method

A curing system and concrete technology, applied in the processing of building materials, construction, building structure, etc., can solve the problems of insufficient spray surface, untimely spraying of health solution, and penetration of cracks, etc., to improve the maintenance effect and avoid pipeline layout interference. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

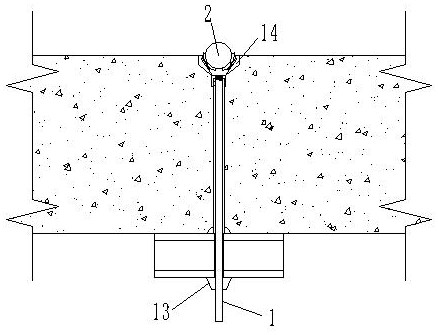

[0034] refer to Figure 1 to Figure 6 As shown, an automatic concrete maintenance system includes a control body 1, a pre-embedded pipeline 2, a standpipe 3, a sprinkler head 6, a gate valve 4 and a timing automatic opening and closing device 5, and the control body 1 is installed on a structural plate and It is detachably connected with the embedded pipeline 2, and the plane where the horizontal diameter of the embedded pipeline 2 is located is consistent with the design height of the floor concrete. The embedded pipeline 2 and the riser 3 are detachably connected and communicated through threads. The head 6 is detachably connected and communicated with the riser 3 through threads. The gate valve 4 and the timing automatic opening and closing device 5 are installed at the water inlet port of the embedded pipeline 2 . The timing automatic opening and closing device 5 is located outside the gate valve 4 . Utilizing the function of the timing automatic opening and closing device...

Embodiment 2

[0042] A maintenance method for an automated concrete maintenance system, comprising the following steps:

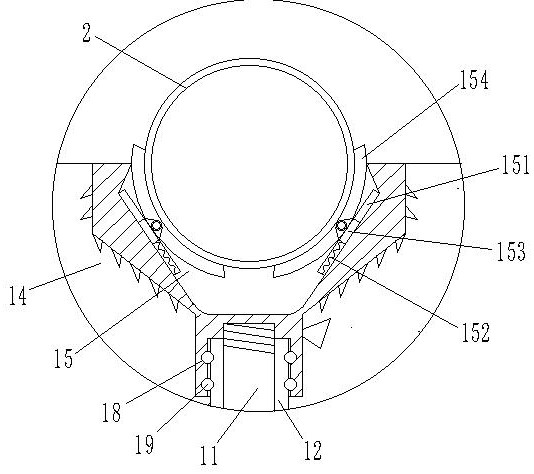

[0043] A. After the installation of the structural plate and the binding of the floor steel bars are completed, the main body rod 11 and the sleeve 12 are installed on the structural plate through the water stop bolt 13, and the bearing body 14 is installed on the top of the main body rod 11 and connected with the top of the sleeve 12. sealed connection;

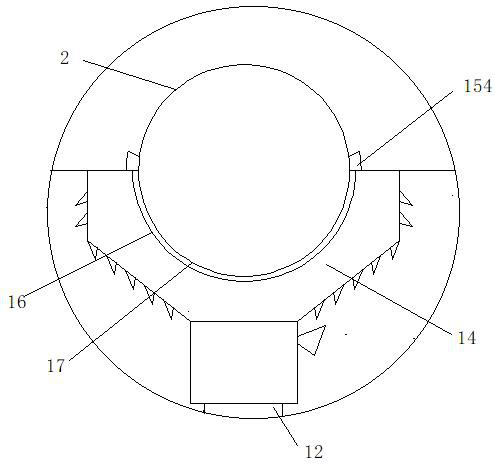

[0044] B. Push the positioning claw 154 upward, and place the embedded pipeline 2 between the two positioning claws 154, the slider 153 drives the positioning claw 154 to move downward under the action of the reset member 152 and hug the embedded pipeline 2 tightly, Ensure that the plane where the horizontal diameter of the embedded pipeline 2 is located is consistent with the design height of the floor concrete;

[0045] C. Install the standpipe 3 on the pre-embedded pipeline 2, and use a common blocking piece to blo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com