A Derrick Defect Inspection Robot

A technology for inspection robots and defects, which is applied in manipulators, program-controlled manipulators, manufacturing tools, etc., and can solve problems such as large data errors, potential safety hazards, and rough detection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below.

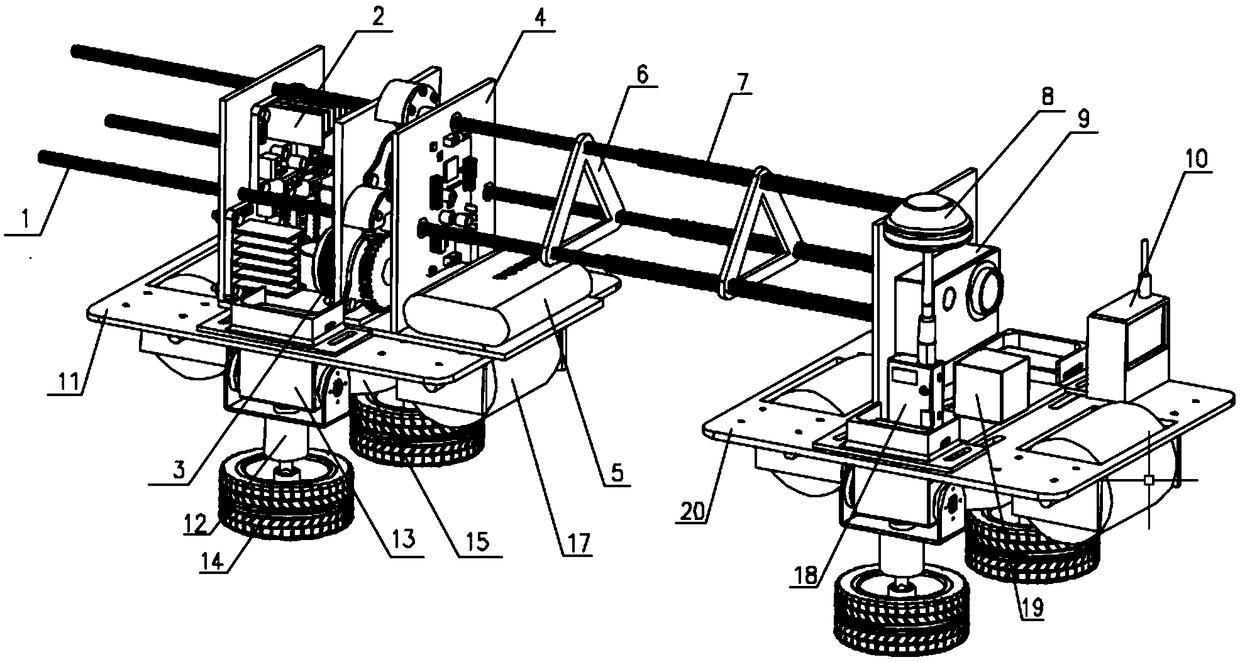

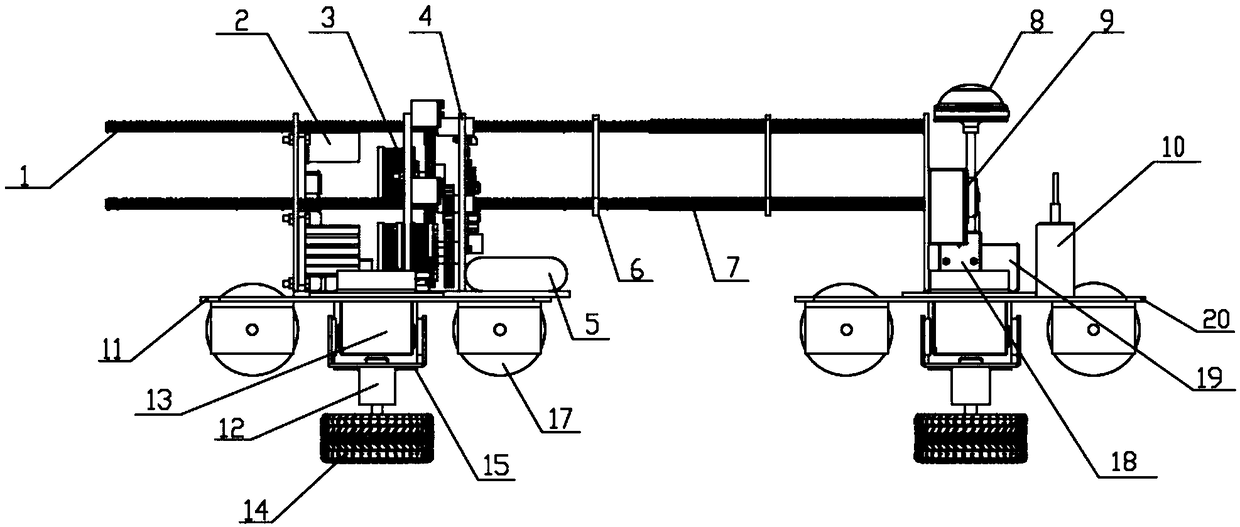

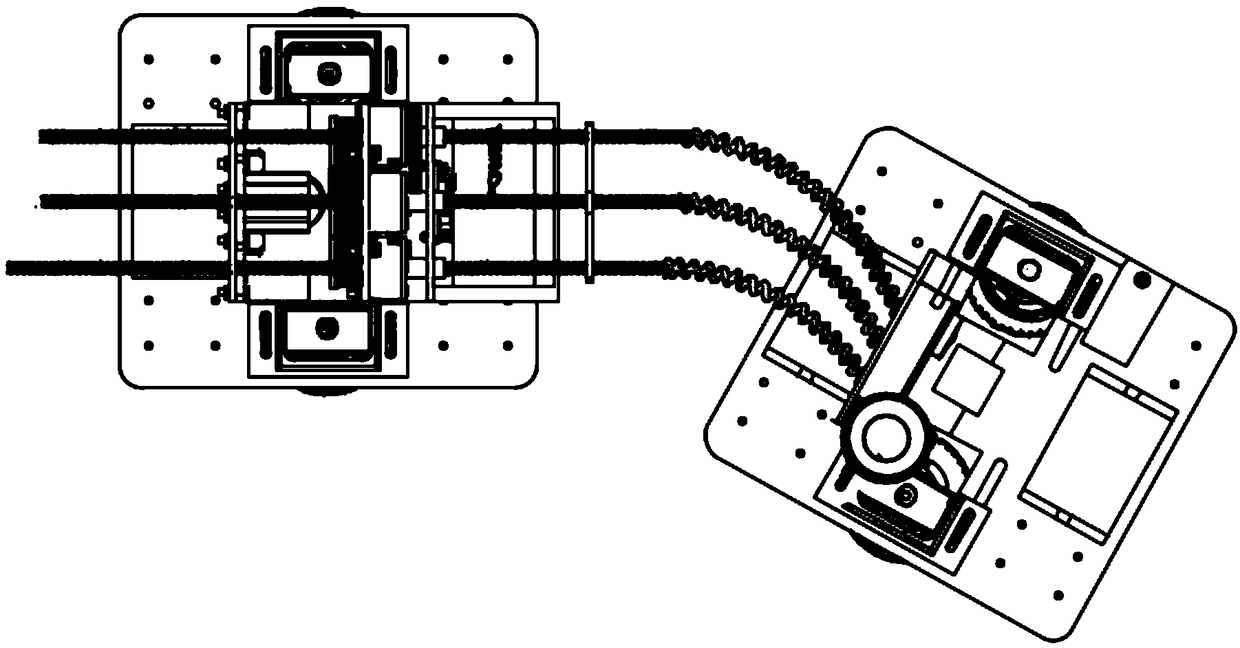

[0025] Such as Figure 1 to Figure 5 Shown, the present invention comprises front car, connecting structure and rear car, and front car is connected with rear car by connecting structure;

[0026]Described front car comprises front vehicle frame 20, antenna, signal transmitter 18, signal receiver 10, motion camera 9, electromagnet 15, front clamping drive mechanism and triaxial acceleration sensor 19, described signal transmitter 18, signal The receiver 10, the motion camera 9 and the triaxial acceleration sensor 19 are arranged on the front frame 20, and the antenna is arranged on the top of the signal transmitter 18; the bottom of the front frame 20 is provided with two groups of rollers 17, and the rollers 17 pass It is hinged with the front frame 20; the front clamping drive mechanism is arranged at the bottom of the front frame 20, and the front clamping drive mechanism is composed of two steering gears 13, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com