Blended elastic yarns and production process thereof

A production process and technology of elastic yarn, applied in the field of blended elastic yarn and its production process, can solve the problems of high shrinkage rate, easy wrinkling of fabrics, large influence on cotton yield, etc., and achieve the effect of good elasticity and excellent comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Example 1 Blended elastic yarn 1

[0047] A milk fiber, spun silk, spandex blended elastic yarn, each component in the blended elastic yarn is calculated according to parts by weight:

[0048] 5 servings of milk fiber, 2tex

[0049] Silk 5 parts, 3tex

[0050] Spandex 1 part, 4tex.

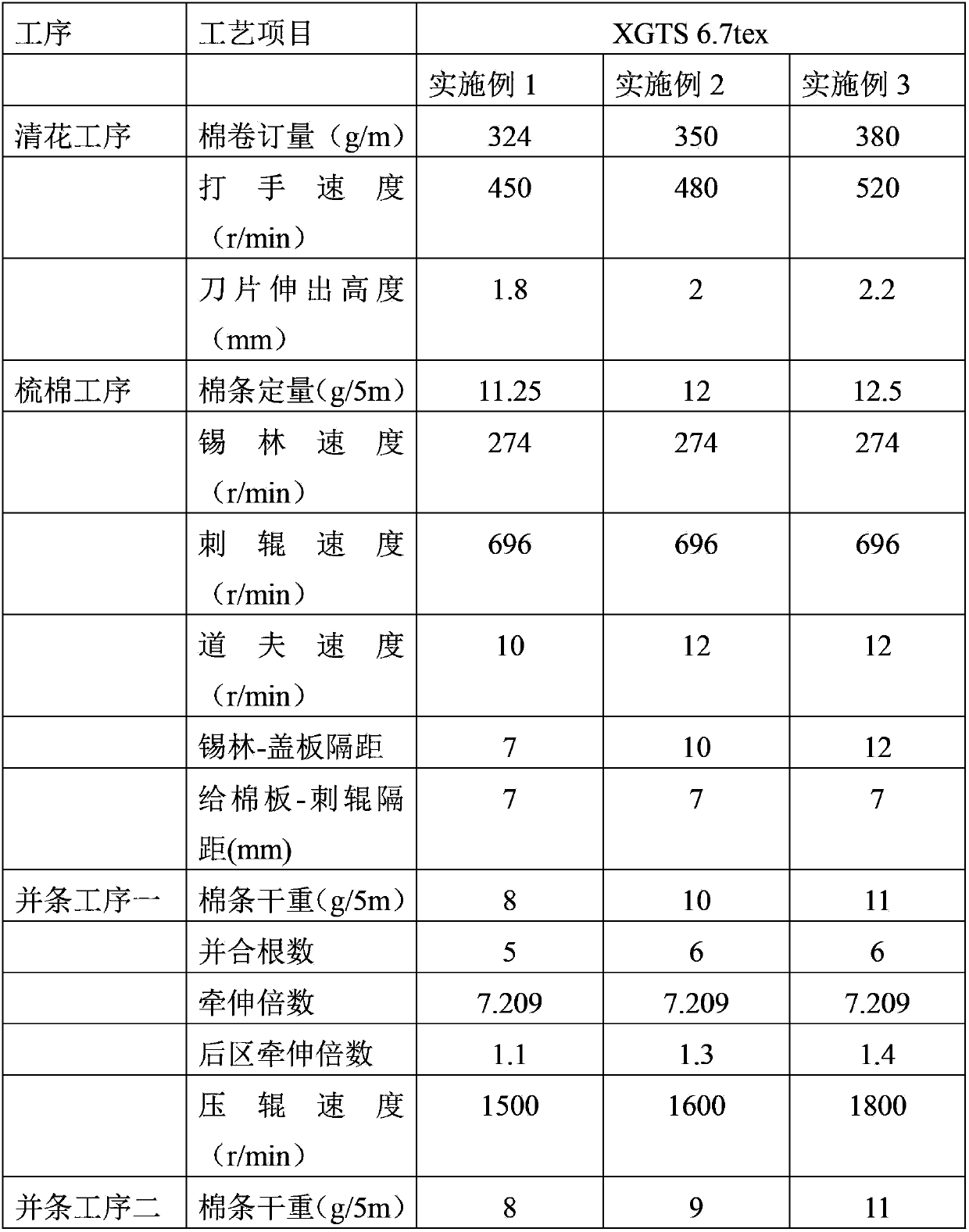

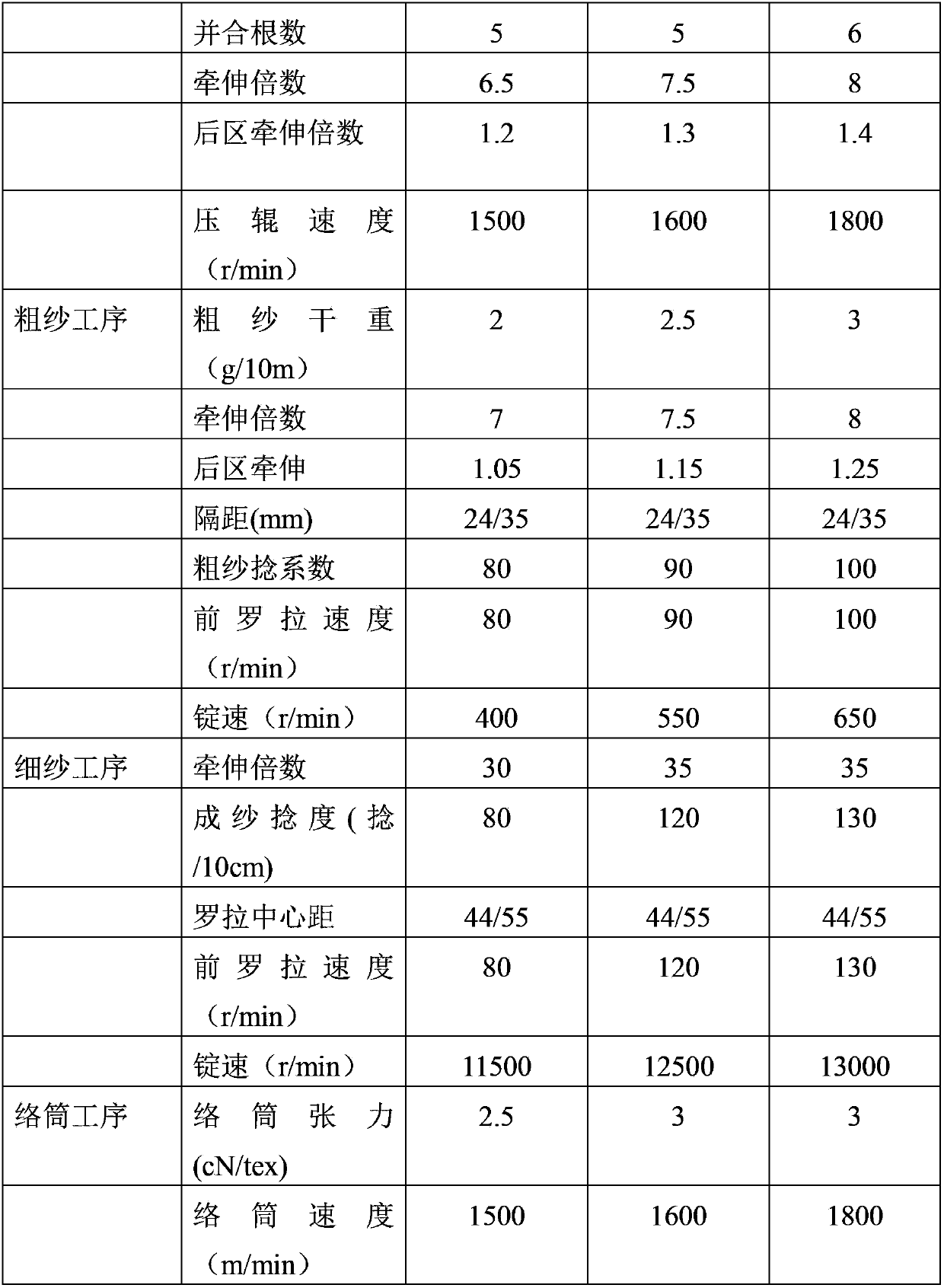

[0051] The number of blended elastic yarn: 15tex+4tex (40s+40D). The specific production process parameters are shown in Table 1.

Embodiment 2

[0052] Example 2 Blended elastic yarn 2

[0053] A milk fiber, spun silk, spandex blended elastic yarn, each component in the blended elastic yarn is calculated according to parts by weight:

[0054] 15 servings of milk fiber, 8dtex

[0055] Silk 15 parts, 3tex

[0056] Spandex 1 part, 4tex.

[0057] The number of blended elastic yarn: 15tex+4tex (40s+40D). The specific production process parameters are shown in Table 1.

Embodiment 3

[0058] Example 3 Blended elastic yarn 3

[0059] A milk fiber, spun silk, spandex blended elastic yarn, each component in the blended elastic yarn is calculated according to parts by weight:

[0060] Milk Fiber 10 servings, 6dtex,

[0061] Silk 10 parts, 3tex,

[0062] Spandex 1 part; 4tex.

[0063] The number of blended elastic yarn: 15tex+4tex (40s+40D). The specific production process parameters are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap