Fabric weft inclination rapid-detection method based on machine vision

A detection method and machine vision technology, which is applied in the inspection of textiles, papermaking, and textile materials, can solve the problems of lower detection accuracy, high algorithm complexity, and large time consumption, and achieve low time and space complexity and eliminate noise pixels. The effect of dots, simple and effective noise pixels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

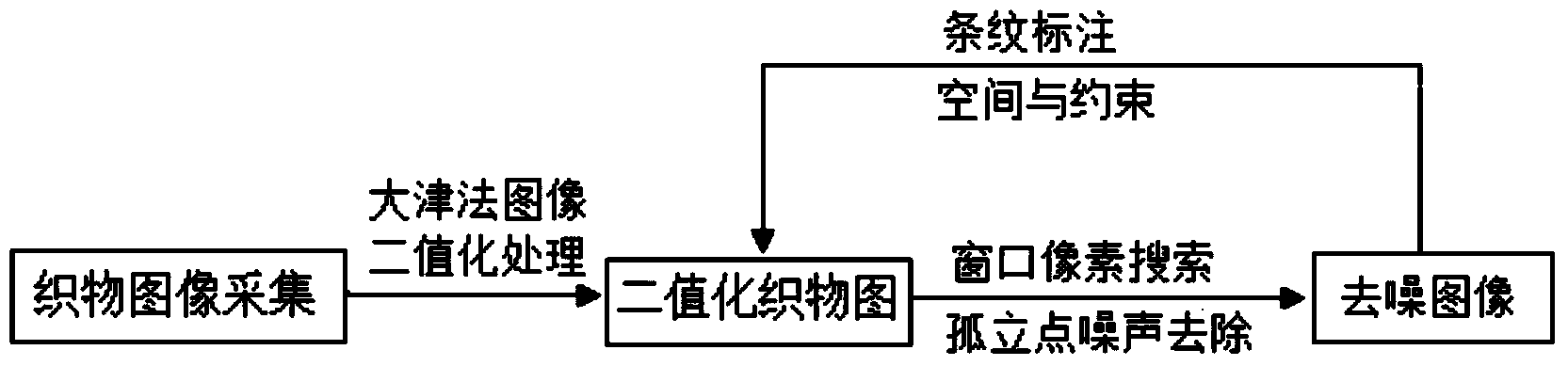

Method used

Image

Examples

Embodiment 1

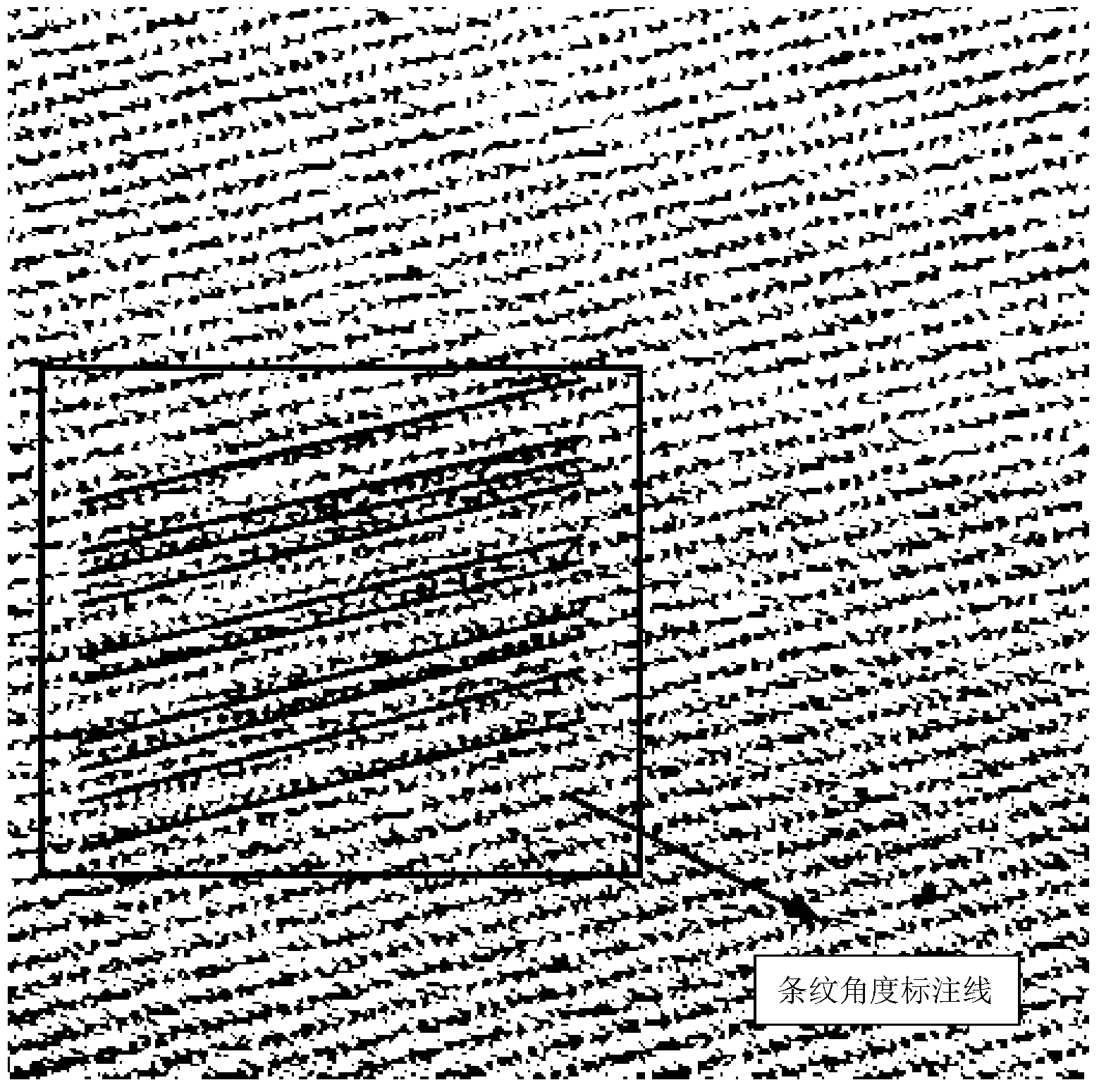

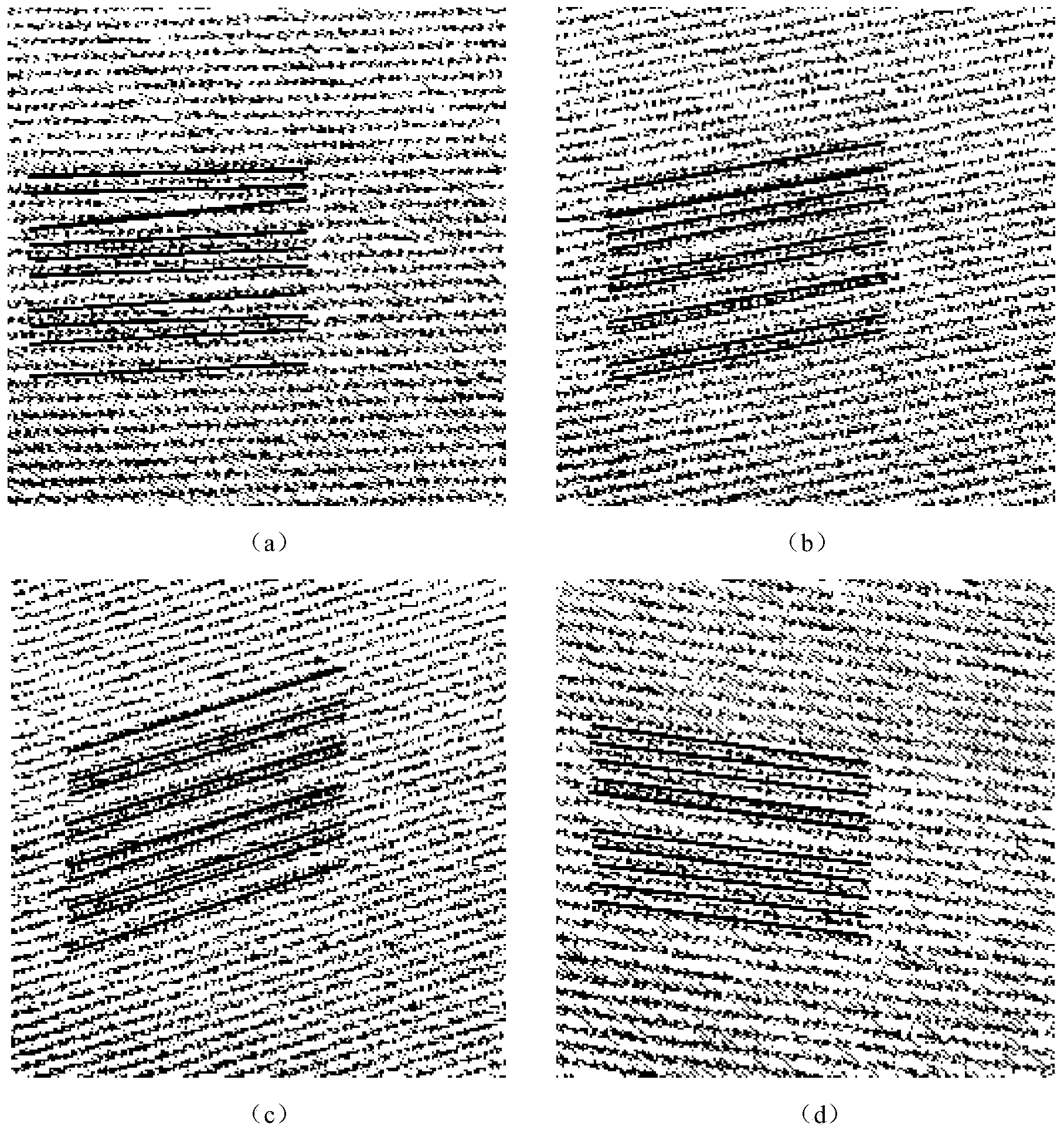

[0042] In order to verify the accuracy, speed and feasibility of the algorithm, denim was used as the experimental sample, and the sample pictures with a given weft angle varying in the range of -20° to +20° were collected. The sample size is 500×500 (pixels), and some sample pictures are as follows image 3 As shown: the comparison between the angle value obtained by the method of the present invention and the actual angle value obtained by detecting the fabric picture with a given weft oblique angle is shown in Table 1.

[0043] Table 1 Comparison table of weft oblique angle detected by the method of the present invention and actual weft oblique angle

[0044]

[0045]

[0046] pass Figure 4 As can be seen from Table 1, the method for fast detection of weft and skewness of fabrics based on machine vision of the present invention, when tracking individual stripes, due to the influence of ambient light, shadow walking, cloth surface flatness, cleanliness, etc. After b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com