Anchor group device of large-sized cable hoisting system track cables

A technology for load-bearing cables and anchor devices, which is applied in the erection/assembly of bridges, bridge parts, bridges, etc., can solve the problems of inconvenient adjustment of load-bearing cables, inconvenience in installation and removal, and impact on the progress of the project, so as to achieve safe and convenient operation, cost saving, Strong construction safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] specific implementation plan

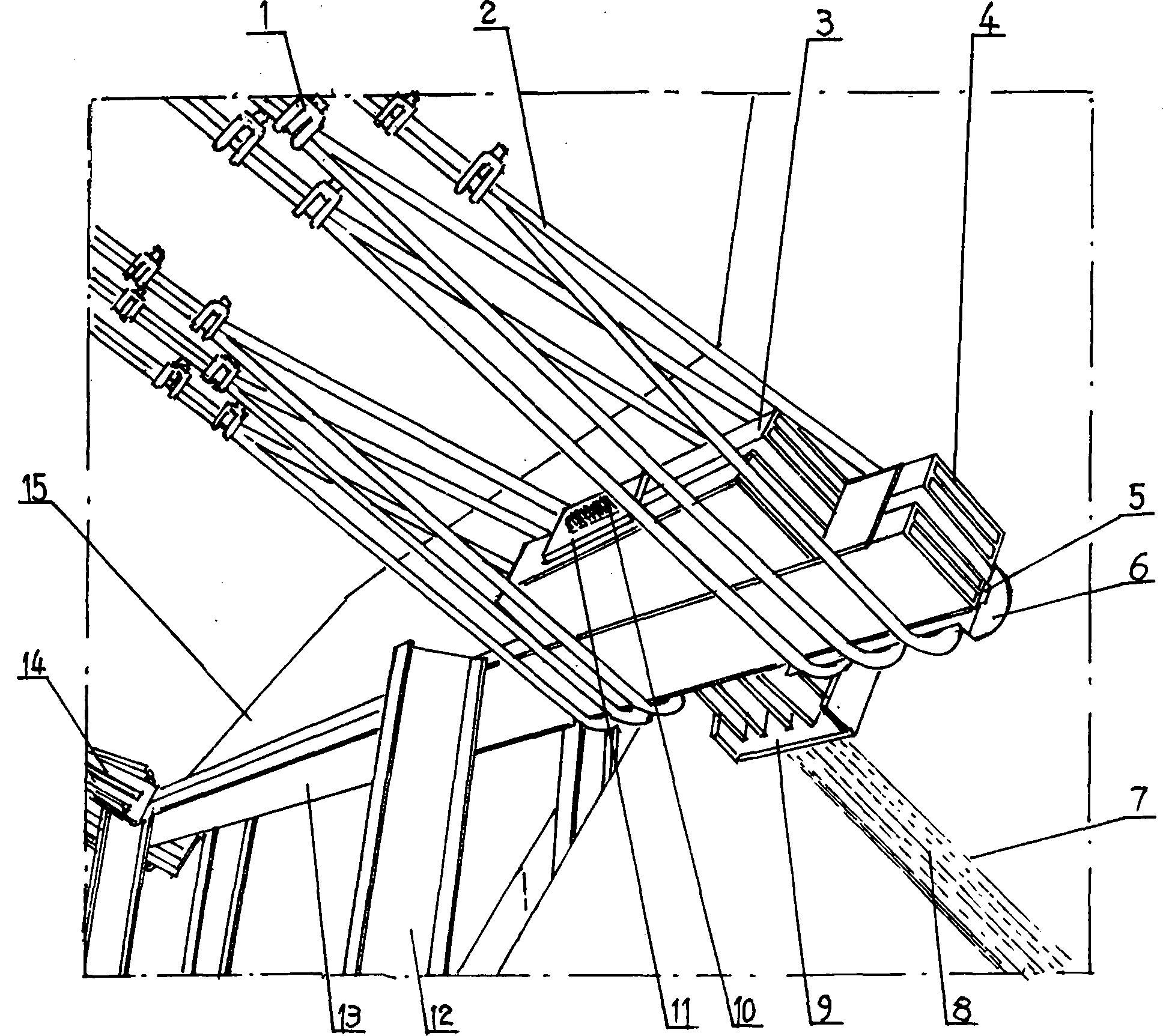

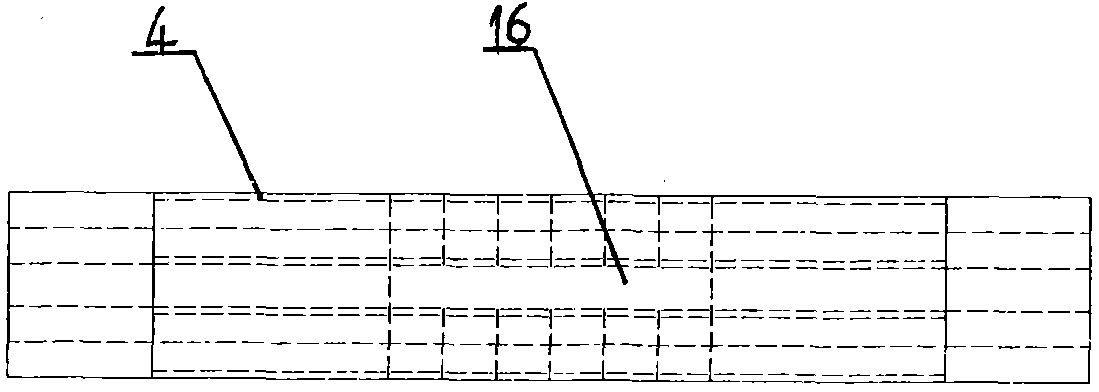

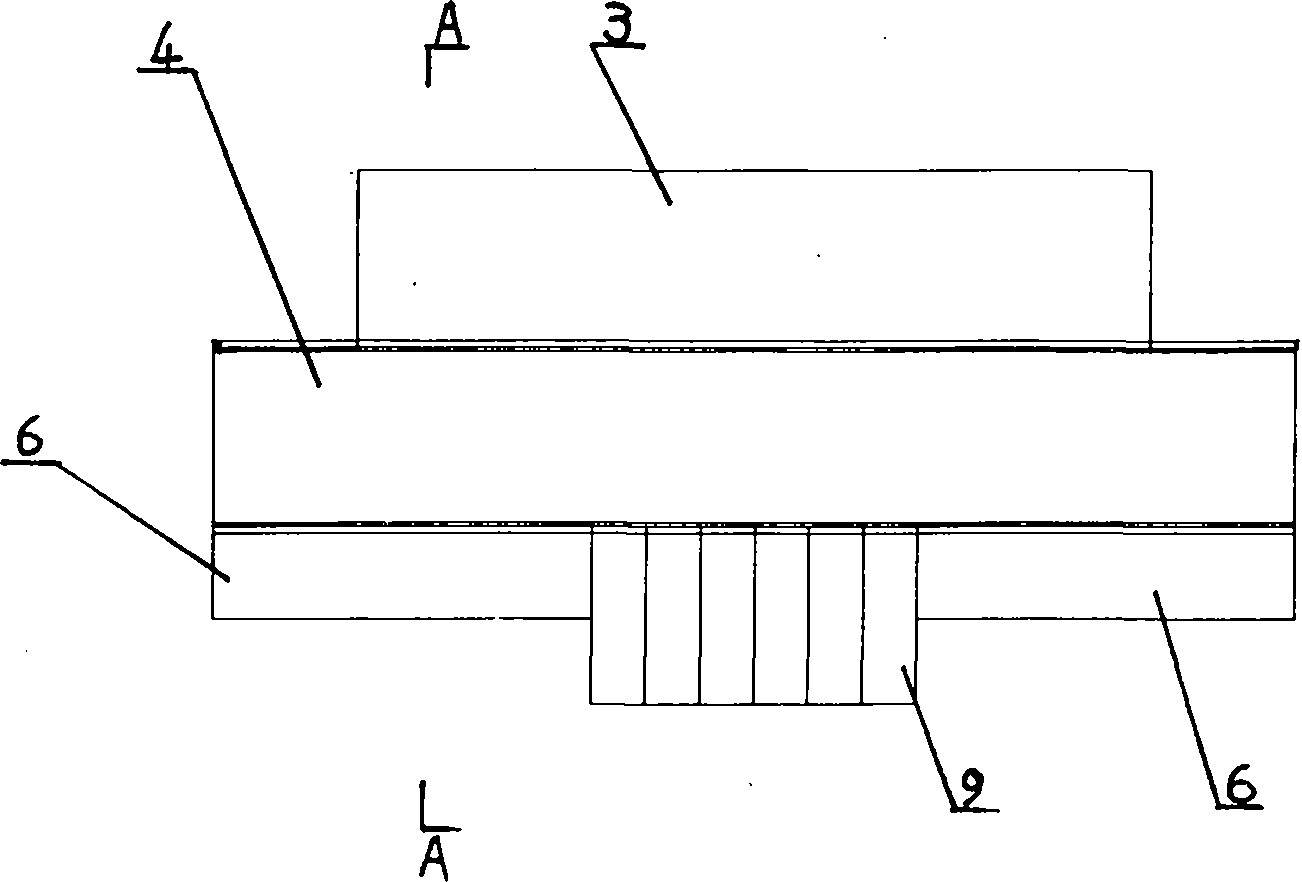

[0022] like Figure 1 to Figure 7 As shown, a large-scale cable crane load-bearing cable group anchor device is composed of a support structure, a load-bearing cable group anchor beam structure, a load-bearing cable anchor beam adjustment structure and an anchor beam moving and fixing structure. in:

[0023] like Figure 1 to Figure 6 As shown, the bracket structure is used to support and fix the load-bearing cable group anchor beam structure, the load-bearing cable anchor beam adjustment structure and the anchor beam moving and fixing structure. It is composed of vertical support beams 12 and horizontal beams 13. The support structure is located at the front of the cement bank foundation 15 . One side of the horizontal beam is fixed between the upper ends of the two vertical beams arranged side by side with a distance apart, and the other side of the horizontal beam is also fixed between the upper ends of the other two vertical beams....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com