Symmetrical suspension splicing bridge support seat end pseudo-suspension splicing construction method

A bridge bearing and construction method technology, applied in the direction of bridges, bridge construction, erection/assembly of bridges, etc., can solve the problems of time-consuming construction, large land occupation, and large traffic impact on the lower part, and achieve the effect of reducing the impact.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical solutions in the present invention will be clearly and completely described below in conjunction with the accompanying drawings in the present invention.

[0025] Please refer to Figure 2-5 , the false cantilever construction method of the symmetrical cantilevered bridge bearing end of the present invention comprises the following steps:

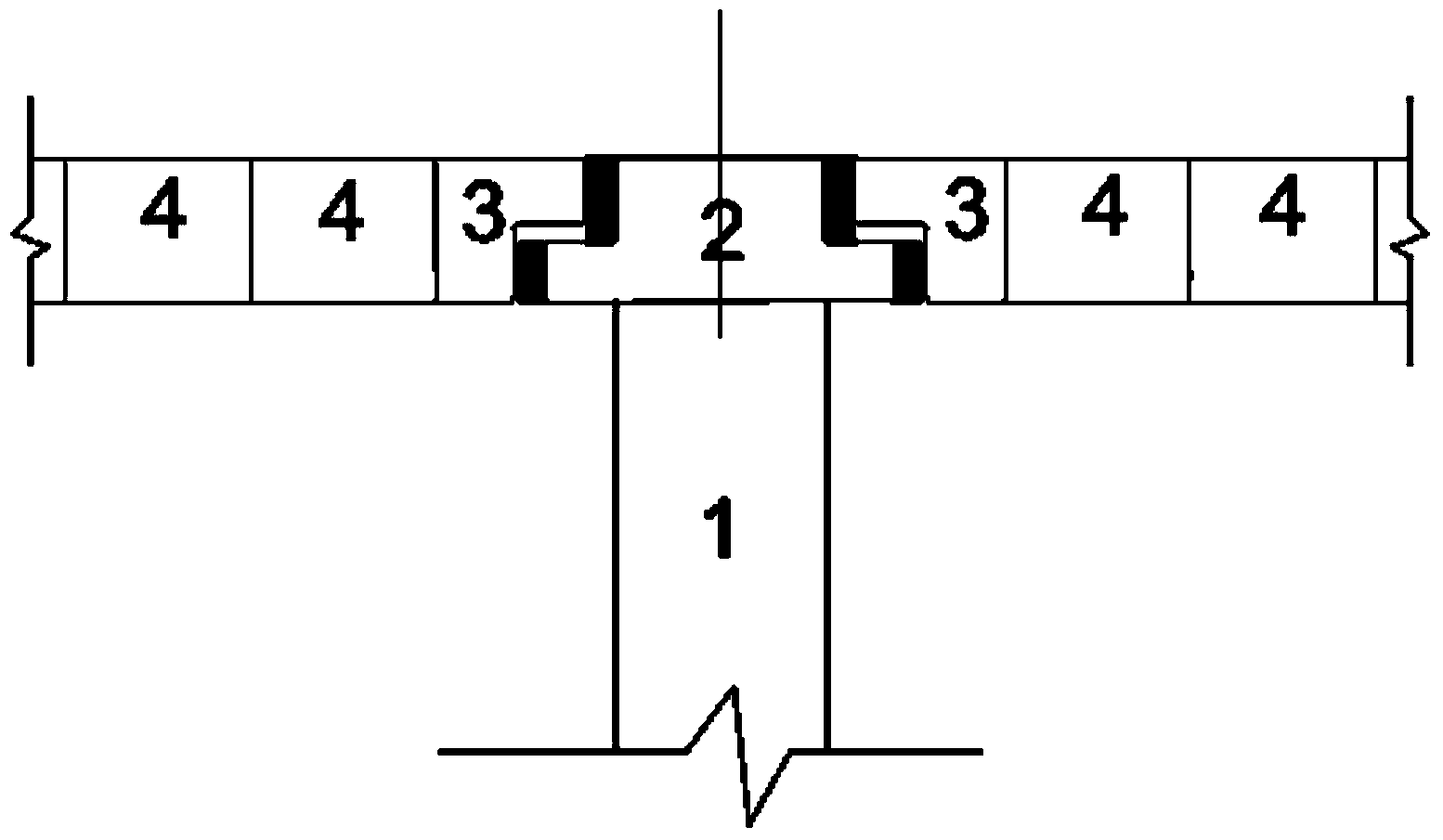

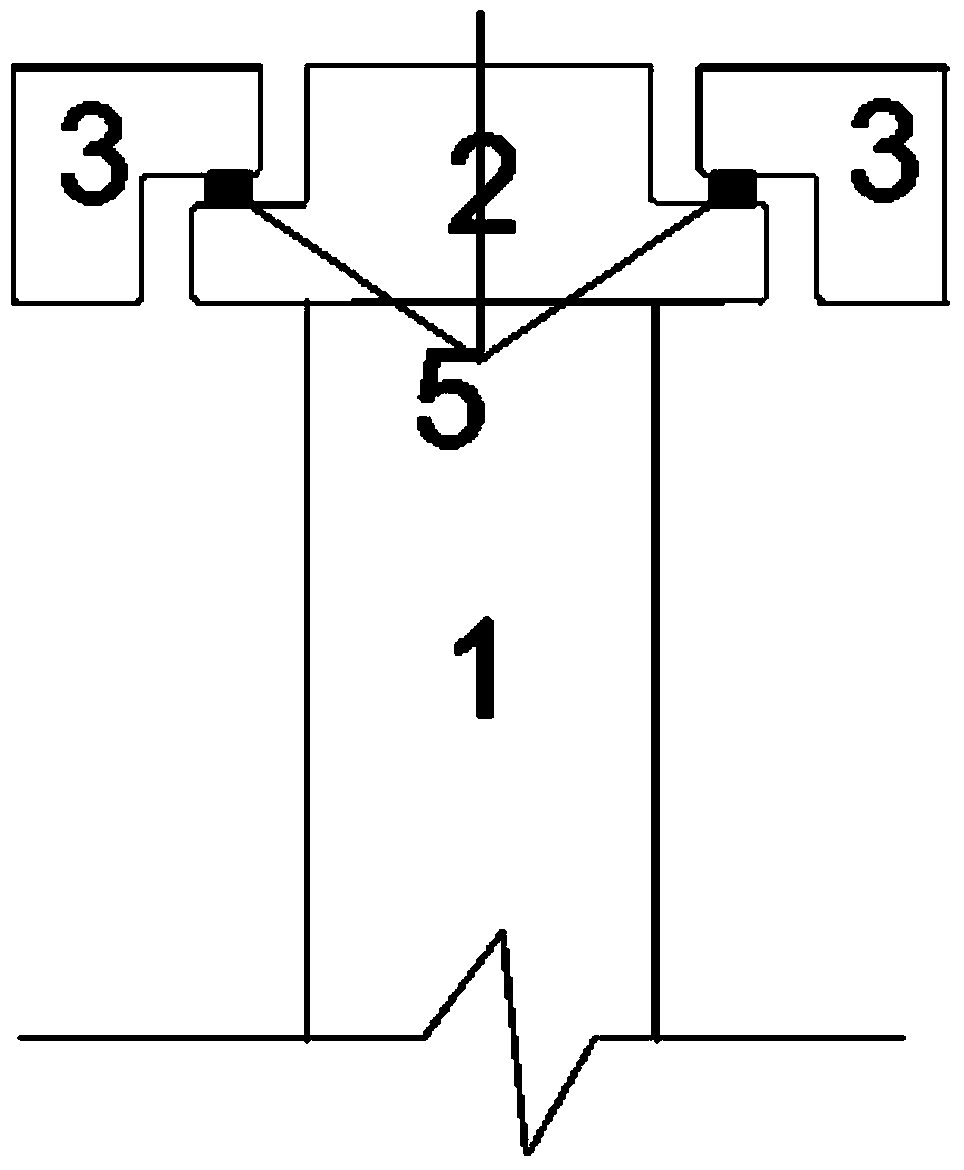

[0026] Step 1. Use a crane, bridge erecting machine or other equipment to hoist the two support segment beams 3 onto the cover beam 2 with a convex support end, and the cover beam 2 with a convex support end is installed on the pier column 1 superior. A temporary support 5 is installed between the cap beam 2 with a convex support end and the support segment beam 3 to bear the vertical force and adjust the position of the support segment beam 3 and the ordinary segment beam 4 (such as figure 2 shown).

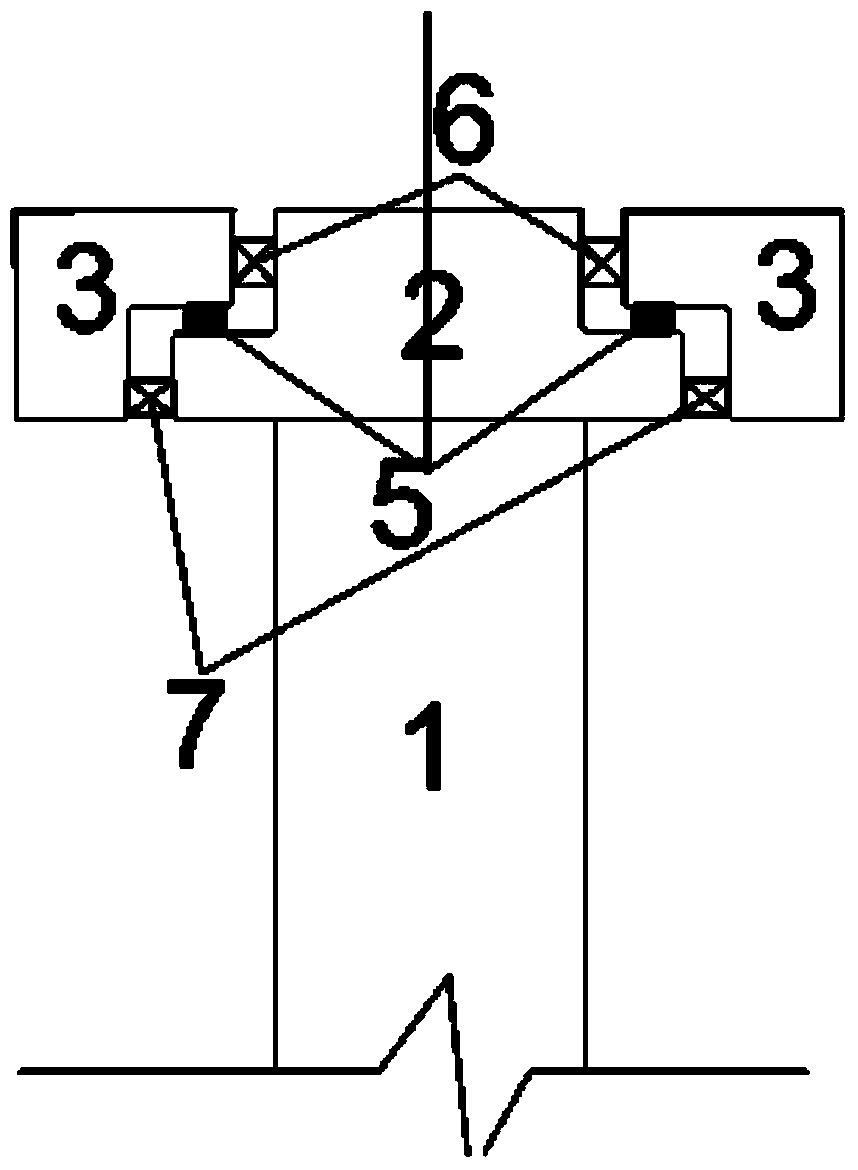

[0027] Step 2. Install the top gasket 6 and the bottom gasket 7 between the support segment beam 3 and the upper an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com