ground beam trench

A technology of ground beams and trenches, applied in water conservancy projects, artificial islands, underwater structures, etc., can solve the problems of cable or pipeline soaking, affecting cables and pipelines, etc., and achieve the effect of saving project cost and quantity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Embodiments of the present invention are described in detail below:

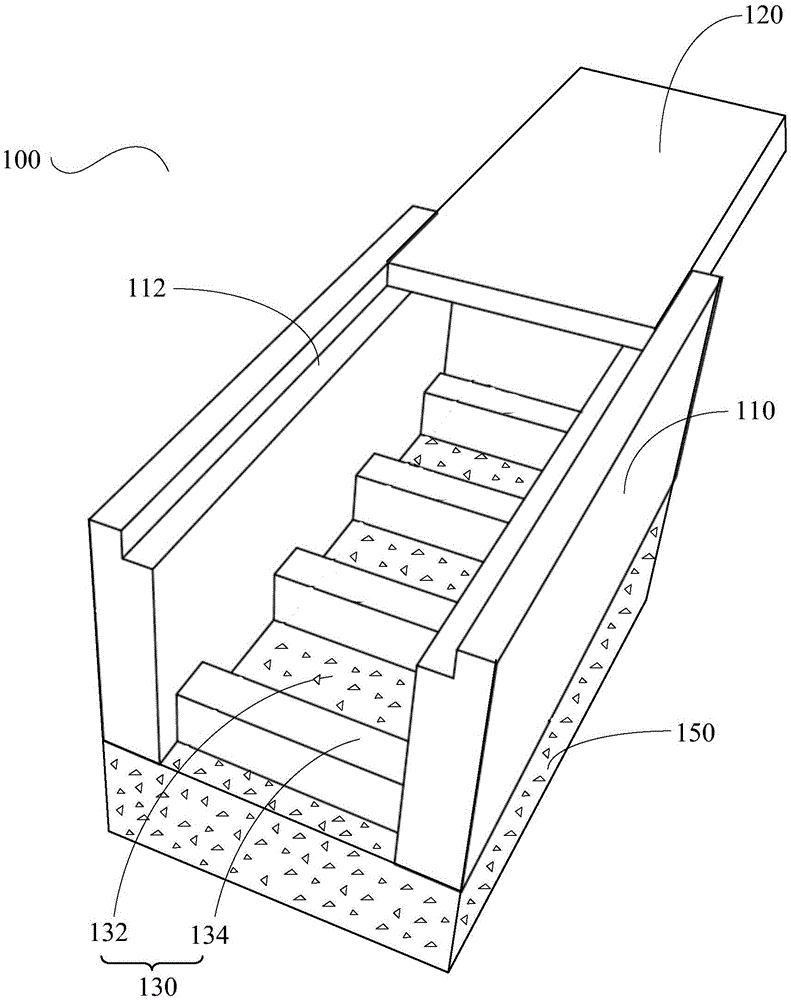

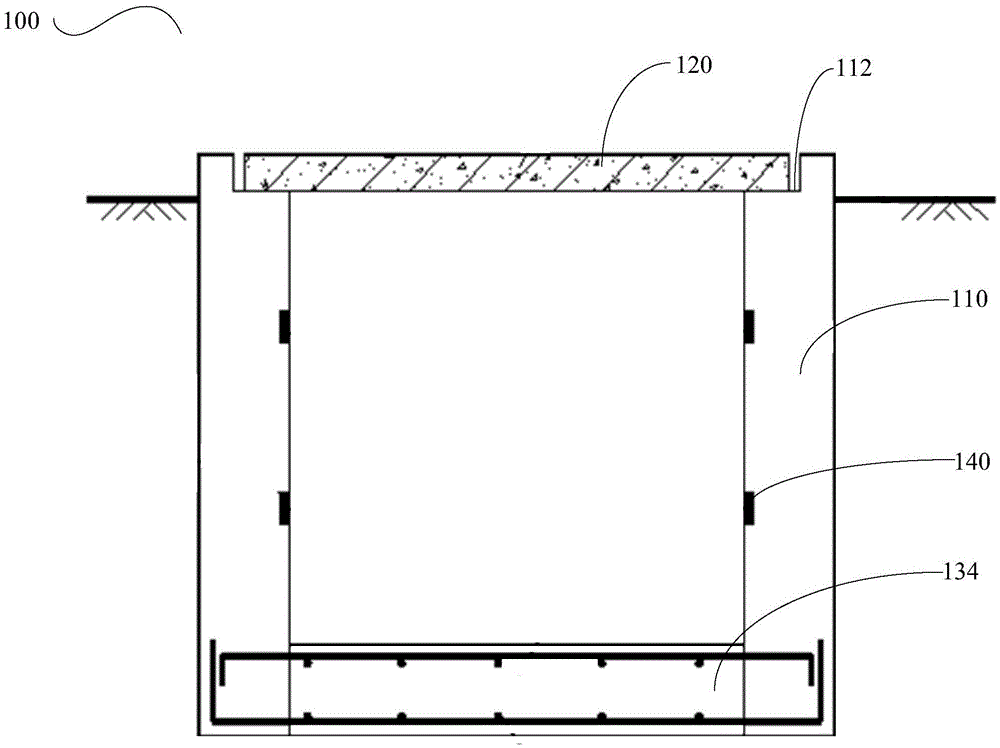

[0026] Such as figure 1 , figure 2 As shown, a ground beam trench 100 includes a trench wall 110, a trench cover 120, a trench bottom 130 and embedded parts 140, the trench bottom 130 is set at the bottom of the trench, and the trench walls 110 are set on both sides of the trench bottom 130, And the ditch bottom 130 is connected to the bottom of the ditch wall 110; the ditch cover 120 is arranged on the upper part of the ditch wall 110, and the embedded part 140 is arranged on the inner wall of the ditch wall 110; the ditch bottom 130 is provided with a drainage hole 132, and the corresponding A gravel layer 150 is provided at the bottom of the ditch bottom 130 .

[0027] The ditch bottom 130 is arranged on the foundation, the ditch wall 110 is arranged on both sides of the ditch bottom 130, and the ditch bottom 130 is connected to the bottom of the ditch wall 110, and the ditch cover 120 is arrang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com