Assembling and positioning device of middle door lock body for railway transportation

A technology for assembling positioning devices and railway transportation, which is applied in vehicle locks, building locks, locks, etc. It can solve the problems of damage to the lock cylinder installation device and troublesome operation, and achieve the effect of convenient operation and accurate positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

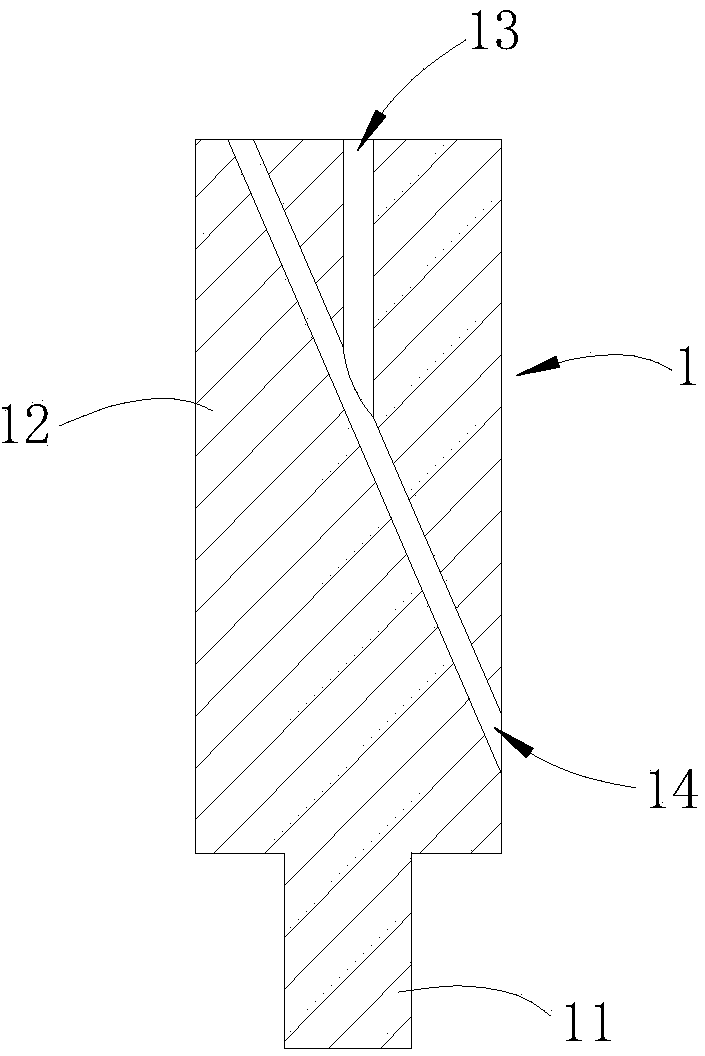

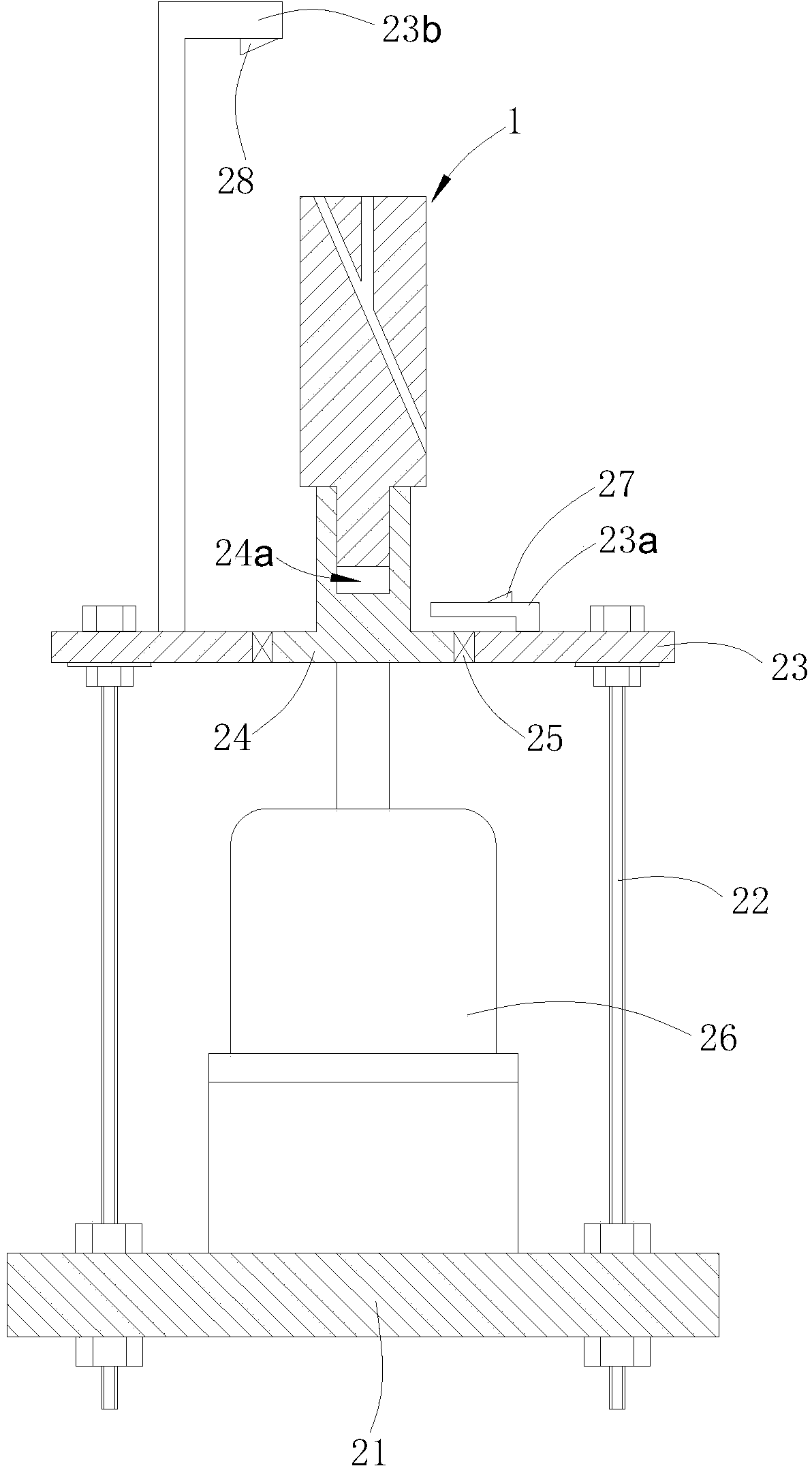

[0014] Such as figure 2 shown

[0015] The device comprises a base 21, a support 22, a rotating platform 23, a low-speed motor 26, a rotating base 24 and a photosensitive positioning assembly.

[0016] The base 21 is fixed with a support 22 by bolts, and the top of the support 22 is also horizontally fixed with a rotating platform 23 by bolts. The center of the rotating platform 23 is equipped with a rotating seat 24, and the rotating platform 23 cooperates with the rotating seat 24 through a bearing 25; Also vertically welded with low-speed motor 26, low-speed motor 26 is on the lower side of rotating platform 23, and the rotating shaft of low-speed motor 26 is connected with the center of the lower end surface of rotating base 24, so that the rotating shaft of low-speed motor 26 and rotating base 24 coaxially rotate, and rotating base The upper end surface of 24 is provided with a groove 24a fitting the head 11 of the middle door lock body 1 .

[0017] An infrared emittin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com