Variable cycle engine with high bypass ratio

A technology with variable cycle engine and large bypass ratio, which is applied in the direction of machine/engine, jet propulsion, etc., can solve the problems of airflow matching of engine components, and achieve the effect of improving airflow matching and improving surge margin.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

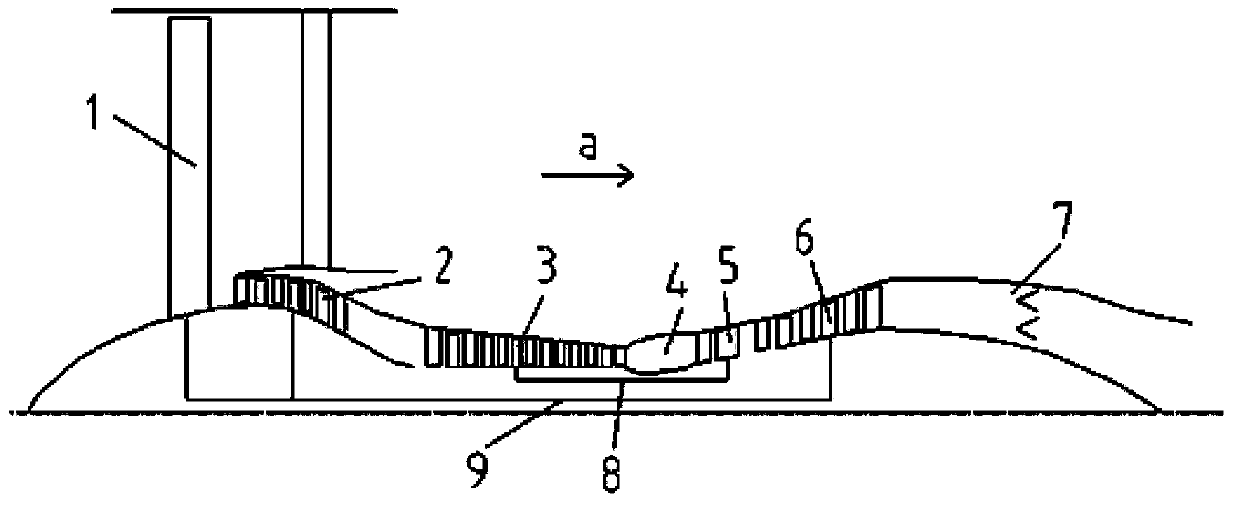

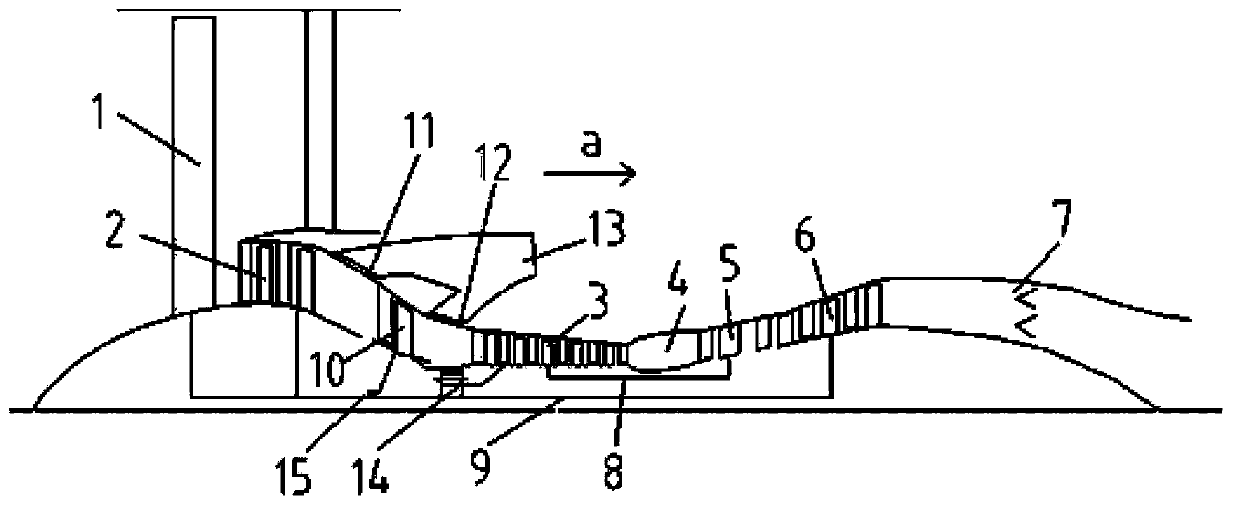

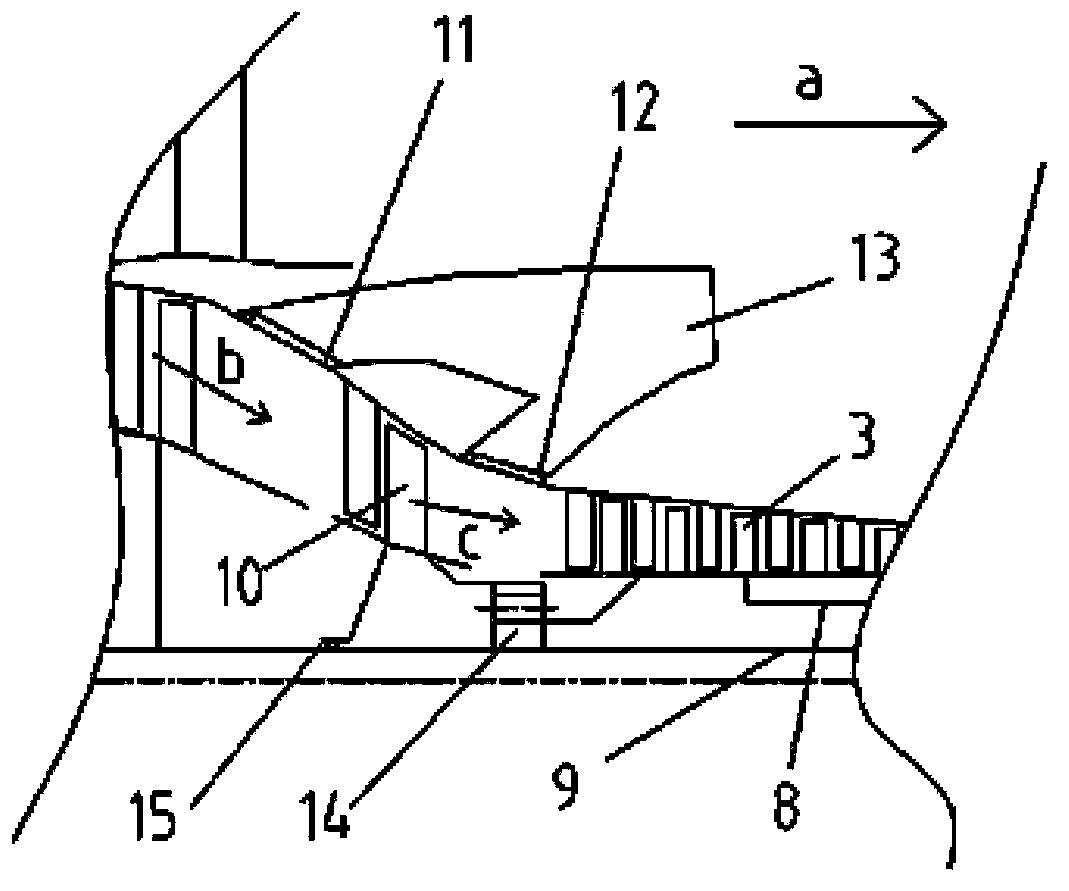

[0032] The technical solutions of the present invention will be described in further detail below with reference to the accompanying drawings and embodiments.

[0033] Such as figure 2 Shown is a schematic structural view of an embodiment of the large bypass ratio variable cycle engine of the present invention. In this embodiment, according to the flow direction a of the airflow along the axial direction, it includes: a front fan 1, a booster stage 2, a rear fan 10, a high-pressure compressor 3, a combustion chamber 4, a high-pressure turbine 5, a low-pressure turbine 6 and a rear fan. Nozzle7. The high-pressure turbine 5 and the low-pressure turbine 6 drive the high-pressure compressor 3 and the booster stage 2 through the high-pressure shaft 8 and the low-pressure shaft 9 respectively. The high-pressure compressor 3 is used to compress the airflow entering the core machine. Combustion chamber 4 accommodates the combustion of an incoming mixture of fuel and compressed air...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com