Universal tire pressure monitoring system maintenance inflating valve and tire pressure monitoring system inflating valve

A monitoring system and tire pressure technology, applied in tire measurement, tire parts, control valves, etc., can solve the problems of scrapped electronic modules and low service life, and achieve the effect of reducing waste and saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

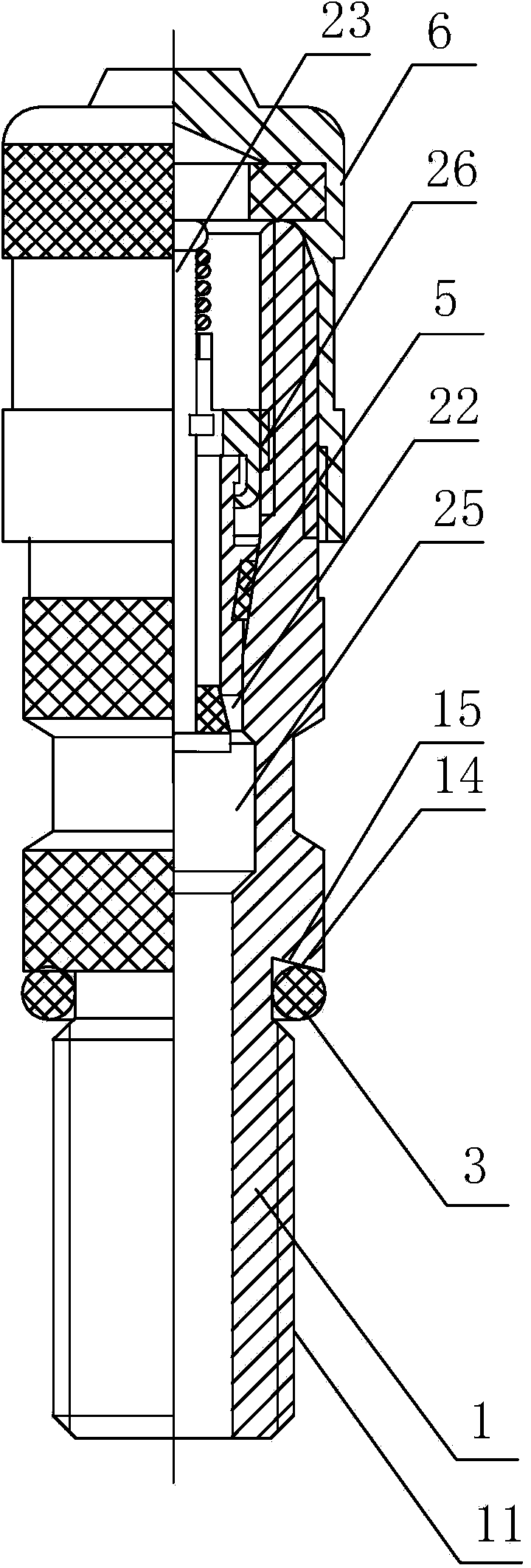

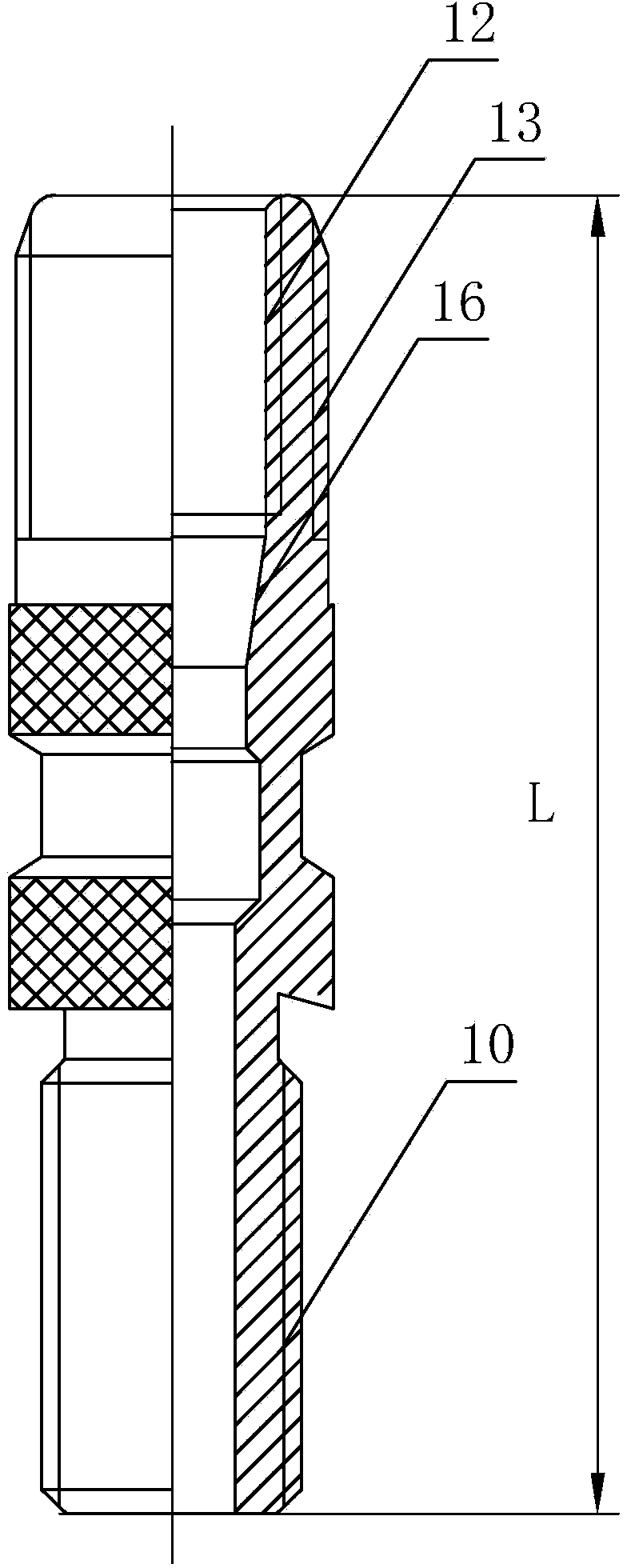

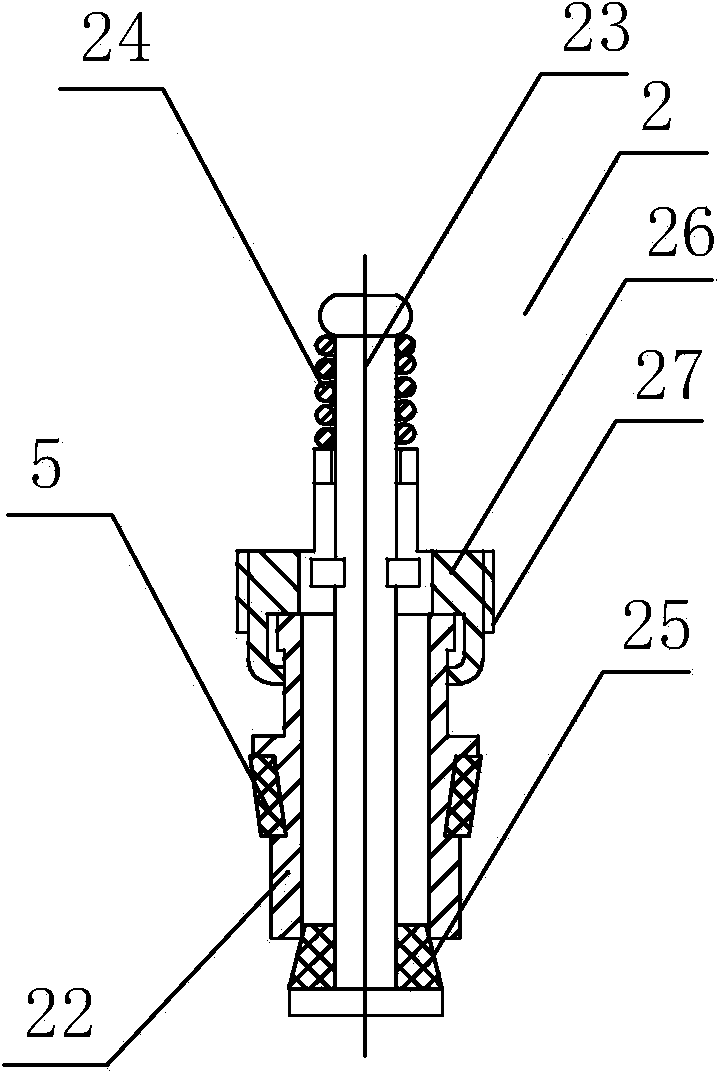

[0026] Refer to attached picture. The maintenance valve 100 of the tire pressure monitoring system provided by the present invention includes a maintenance valve body 1 and a maintenance valve core 2 in the form of a hollow cylinder. The rear part of the maintenance valve body has a connecting section 10. The connecting section has an external thread 11 , and the connecting section 10 is used to be screwed into the remaining part 101 of the valve body of the tire pressure monitoring system valve body after a section has been removed so as to be threadedly connected with the front part of the remaining part 1011 .

[0027] The outer surface of the middle part of the maintenance valve body 1 is provided with a first sealing ring 3, and the first sealing ring 3 is used to seal the front of the maintenance valve and the remaining part 101 of the valve body of the tire pressure monitoring system threadedly connected with it. junctions between parts.

[0028] The length L of the mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com