Grounding method for high and low-voltage line maintenance operation and special grounding wire grounding body

A line maintenance and grounding wire technology, applied in the direction of line/collector parts, connections, circuits, etc., can solve the problems of inability to accurately grasp the depth of the grounding body, hidden dangers to personal safety of staff, and insufficient depth of the grounding body. , to achieve the effect of shortening maintenance time, eliminating potential safety hazards, and improving safety and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described through the embodiments below in conjunction with the accompanying drawings.

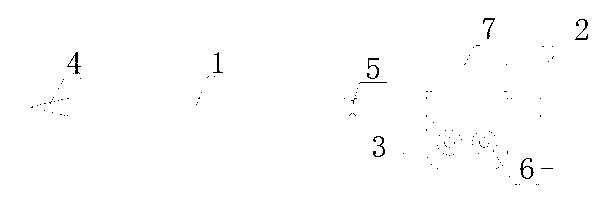

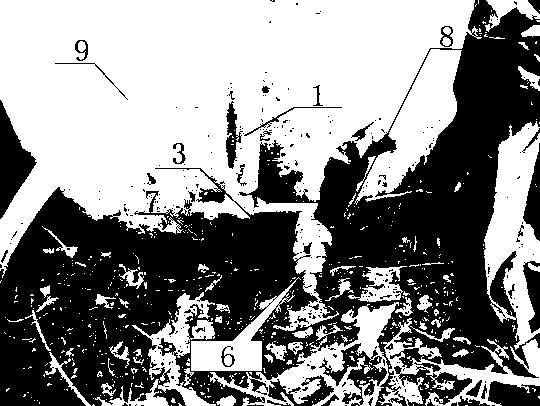

[0014] A special grounding wire grounding body for high and low voltage line maintenance operations, including a grounding rod 1, a hitting bar 2 and a terminal board 3, the diameter of the grounding rod is 1.5 cm, the length is 87 cm, the lower end is a conical structure 4, and the grounding rod is set Hit the crossbar, which has a diameter of 1.5 centimeters and a length of 12 centimeters, and is vertically arranged with the grounding pole; on the grounding pole at a distance of 61 centimeters from the apex of the conical structure at the lower end, a closed ring 5 is set as the lowest ground entry mark; On the grounding rod above the closed ring, a terminal board is set, and two connection holes are provided on the terminal rod, and the connection holes are pierced with bolts 6, and the bolts match nuts for connecting the grounding wire; the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com