High-voltage constant-current exploder for industrial electronic detonator series network

An electronic detonator and high-voltage constant-current technology are applied to high-voltage constant-current detonators and the detonation of industrial electronic detonators. It can solve the problems of rising cost, password detonation can not meet the requirements of detonation security, etc., and achieve the effect of improving security, facilitating use and management, and improving use security.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to better explain the present invention and facilitate understanding, the present invention will be described in detail below through specific embodiments in conjunction with the accompanying drawings.

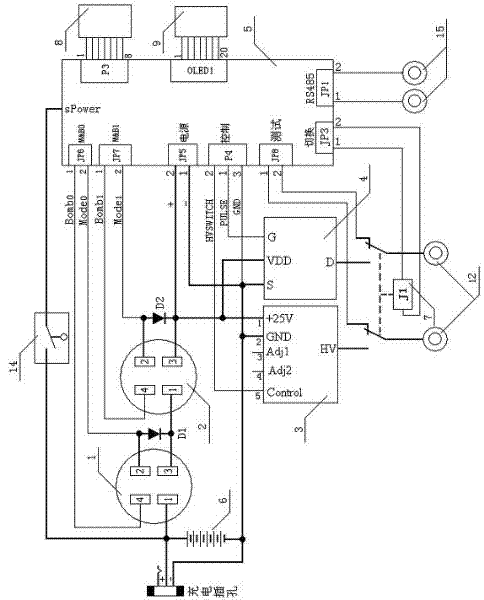

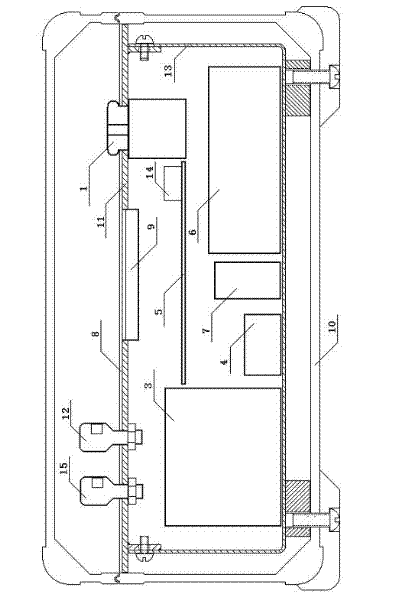

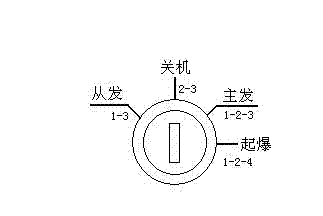

[0032] see Figure 1 to Figure 3 , The present invention relates to a high-voltage constant-current detonator used in a series network of industrial electronic detonators, comprising a high-voltage constant-current power supply 3 , a high-voltage electronic switch 4 and a CPU circuit 5 .

[0033] The high-voltage constant-current power supply can convert the output from the low-voltage DC power supply into a high-voltage and constant charging current to output to the series network of industrial electronic detonators, and form a high-voltage constant-current output loop with the series network of industrial electronic detonators, and its input can be The output end of the low-voltage DC power supply is connected, and the output end is connected to the series ne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com