Circulation board of heat exchanger, heat exchanging unit of heat exchanger and heat exchanger

A technology of heat exchange units and heat exchangers, applied in evaporators/condensers, laminated components, heat exchange equipment, etc., can solve the problems of small effective space, affecting the heat exchange effect of plate heat exchangers, etc. Effect of thermal efficiency and heat transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

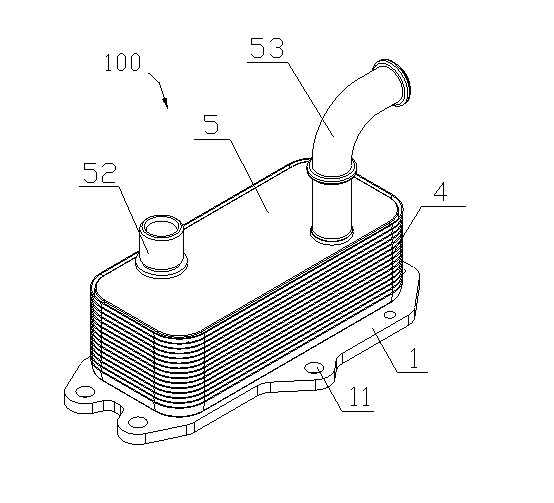

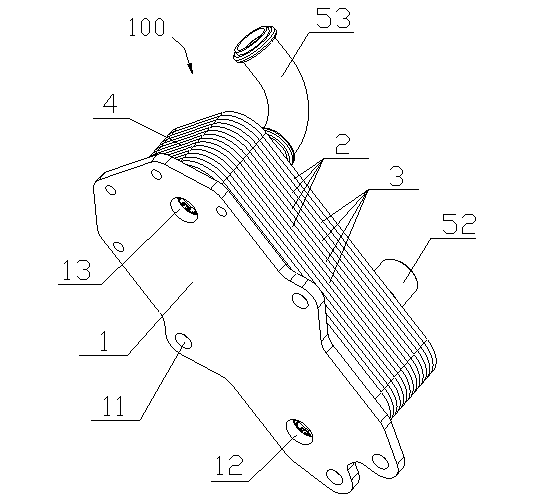

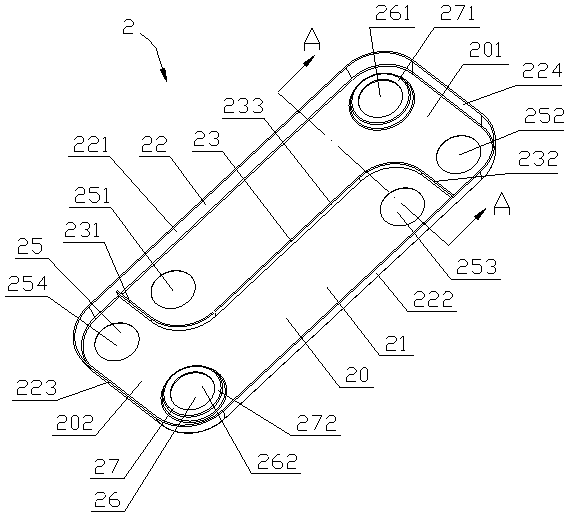

[0039] Please refer to Figure 1 to Figure 10 As shown, the present invention discloses a heat exchanger 100 , which includes a bottom plate 1 , a plurality of stacked heat exchange units 4 installed on the bottom plate 1 , and a top plate 5 installed on the uppermost heat exchange unit 4 . The heat exchange unit 4 includes a first circulation plate 2 and a second circulation plate 3 stacked adjacently. In the illustrated embodiment of the present invention, the heat exchanger 100 is a plate-fin heat exchanger, and the first circulation plate 2 is provided with a first fin 24 (refer to Figure 5 shown), the second flow plate 3 is provided with second fins 34 (refer to Figure 8 shown).

[0040] Please refer to figure 1 and figure 2 As shown, the bottom plate 1 protrudes from the heat exchange unit 4 in the circumferential direction, and the bottom plate 1 is provided with a number of mounting holes 11 for screws (not shown) to pass through, so as to realize the replacemen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com