A Long Gauge Carbon Fiber Strain Sensor Device

A strain sensing, carbon fiber technology, applied in the direction of electric/magnetic solid deformation measurement, electromagnetic measurement devices, etc., can solve the problems of carbon fiber sensing core wire dispersion, manufacturing process influence, inability to meet the requirements of small strain measurement, etc., to improve the operation. performance, solving measurement requirements, and improving the effect of accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

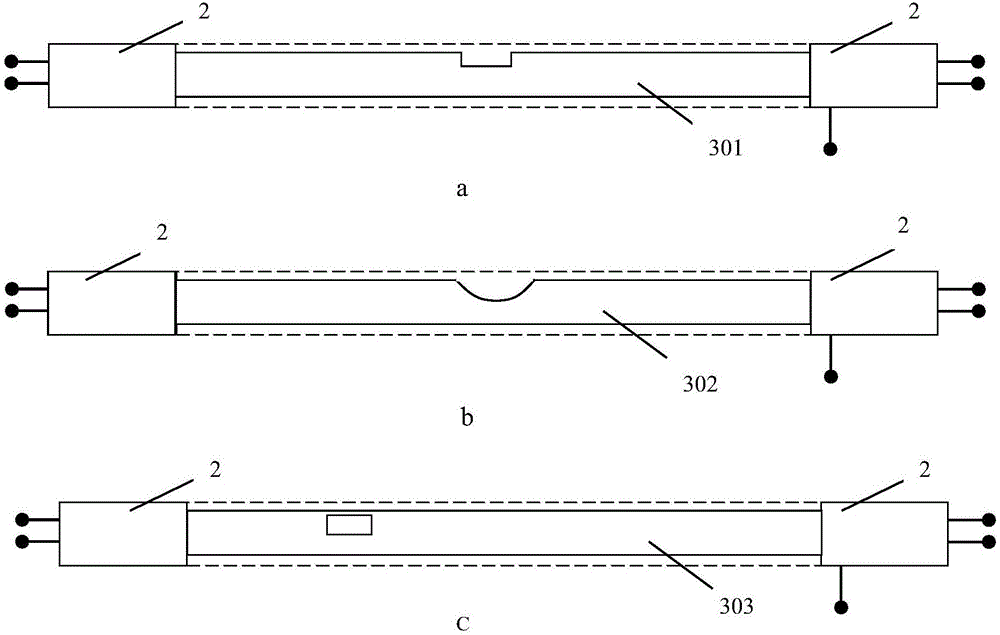

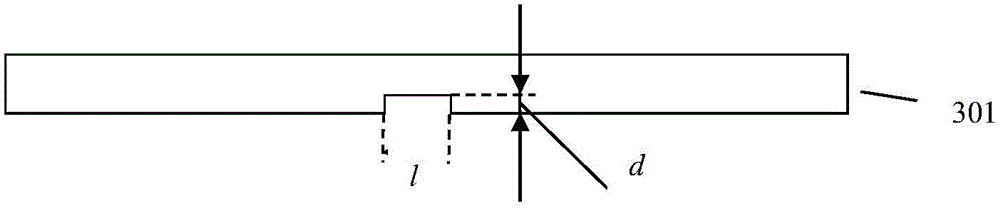

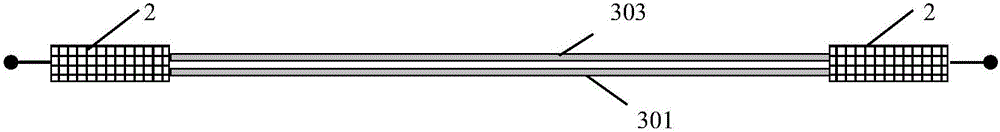

Method used

Image

Examples

example

[0036] As can be seen from the results of the unidirectional tension loading test of the long gauge carbon fiber strain sensing device of the present invention for 3 gauge lengths with different cutout areas of 500 millimeters, as Image 6 As shown, as the incision area increases, the signal obtained by the long-gauge carbon fiber strain sensor has an obvious sensitization effect, and its magnification gradually increases with the incision area, and the linearity of the signal obtained during the entire measurement process very good. Through the correction coefficient, comparing the measurement results with the set reference strain, it is found that the signals obtained by the long-gauge carbon fiber strain sensor have good consistency in different measurement ranges.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com