Non-contact type detection equipment

A testing equipment, non-contact technology, applied in the direction of measuring devices, optical testing flaws/defects, instruments, etc., can solve the problems of equipment size and volume, unfavorable use, unfavorable testing equipment miniaturization and portability, etc., to reduce The time of 3D scanning, reducing the overall size and volume, and realizing the effect of online 3D inspection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

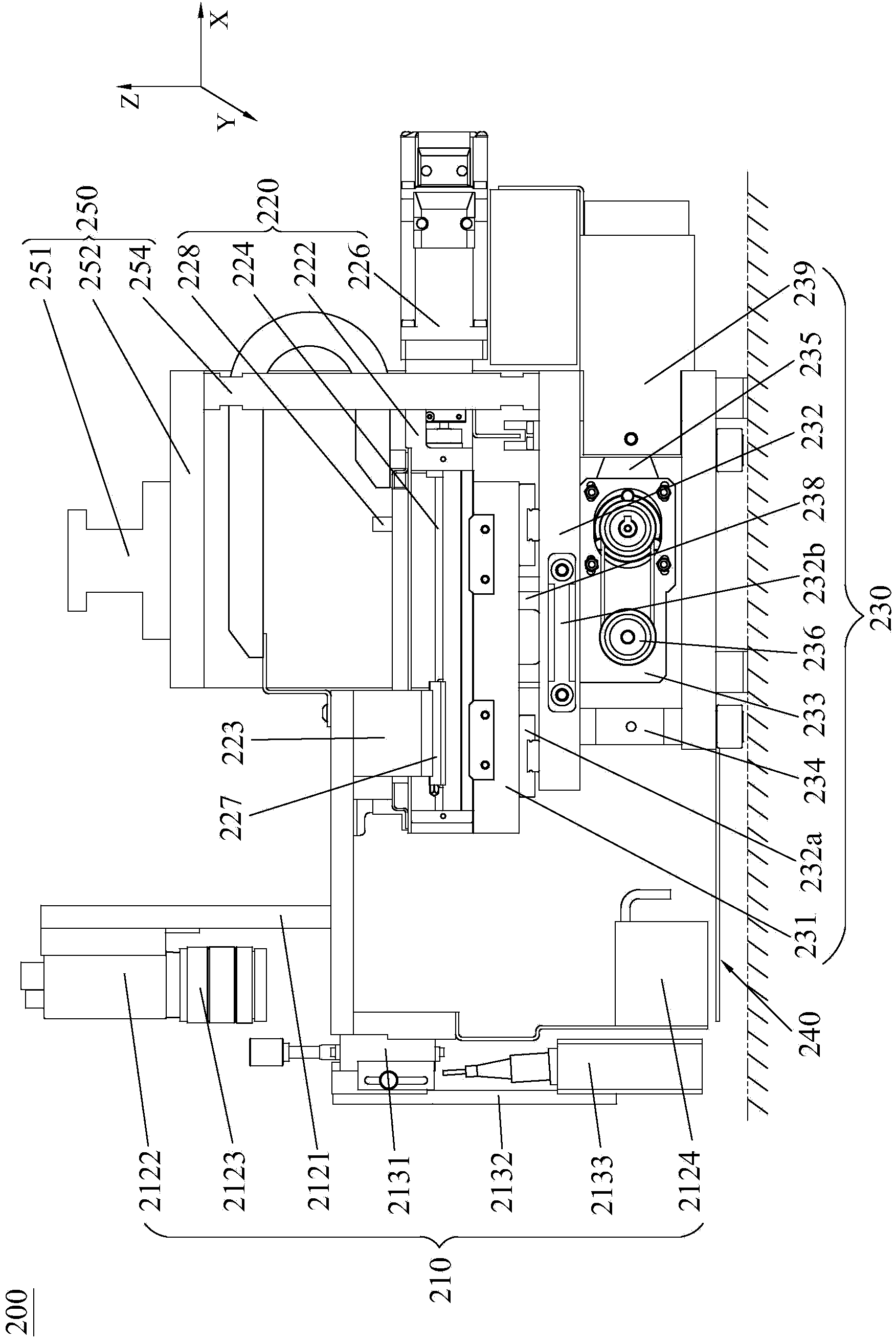

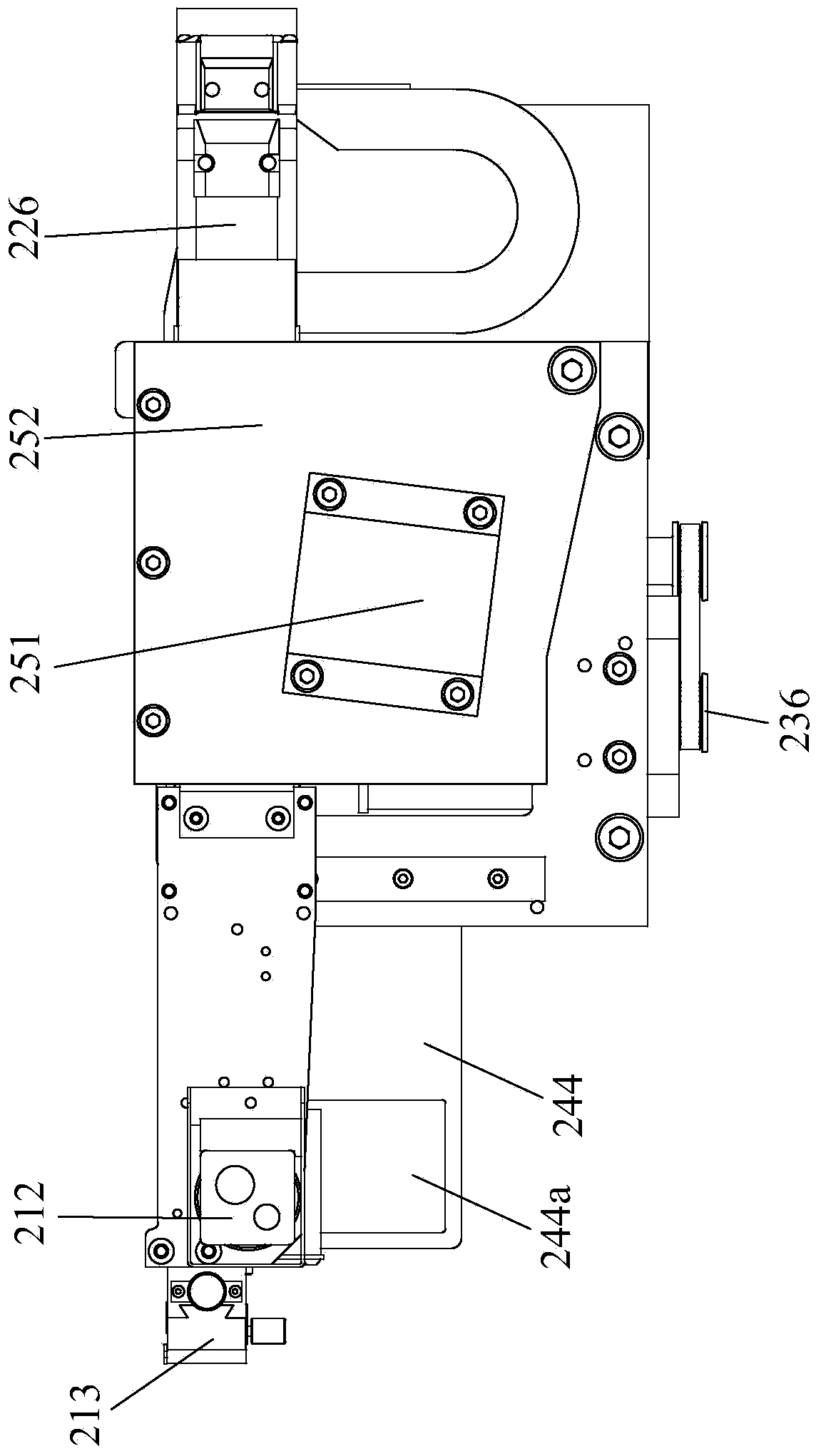

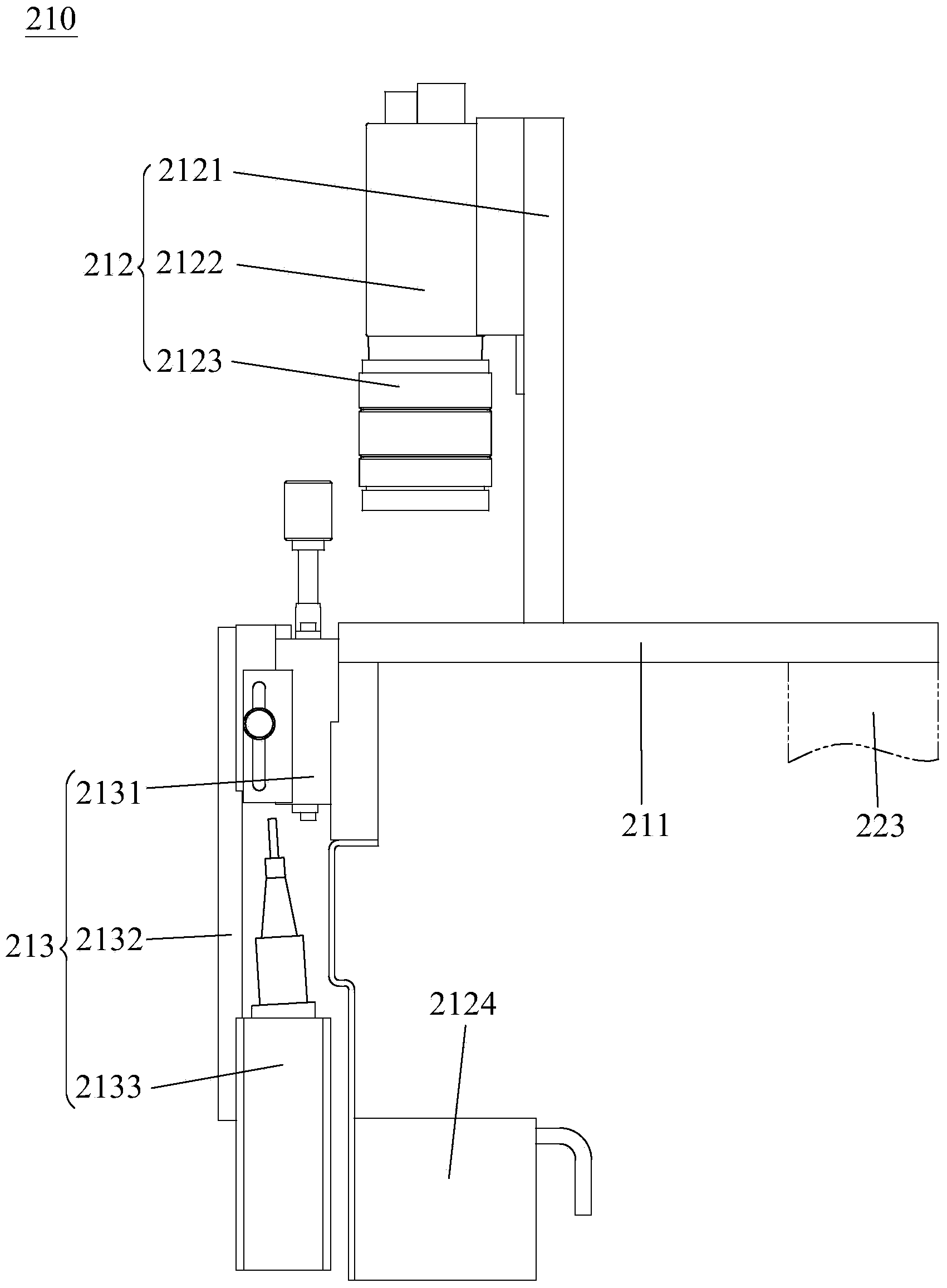

[0064] Embodiments of the present invention will now be described with reference to the drawings, in which like reference numerals represent like elements. The non-contact detection equipment 200 provided by the present invention is suitable for quickly and automatically identifying the defects existing on the surface of large components and can measure the size of the defects, which meets the time requirements of online detection and does not affect the surface of the detection object. cause injury; and is able to perform work independently and adjust itself to work conditions and circumstances.

[0065] Such as Figure 1-Figure 3 As shown, the non-contact detection equipment 200 provided by the present invention includes a detection device 210, an X-axis manipulator 220, a Y-axis transfer platform 230, a lower adapter plate component 240 and an upper connecting support frame 250; wherein, the The lower end of the Y-axis transfer platform 230 is fixed on the lower adapter pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com