Water-cooled cable connecting device

A technology of connecting device and water-cooled cable, which is applied in the direction of two-part connecting device, parts of connecting device, connection, etc., can solve the problems of unreasonable structure, poor working reliability, potential safety hazards, etc., and achieve reasonable structure and reliable working life. 、Reliable effect of mechanical connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and typical embodiments.

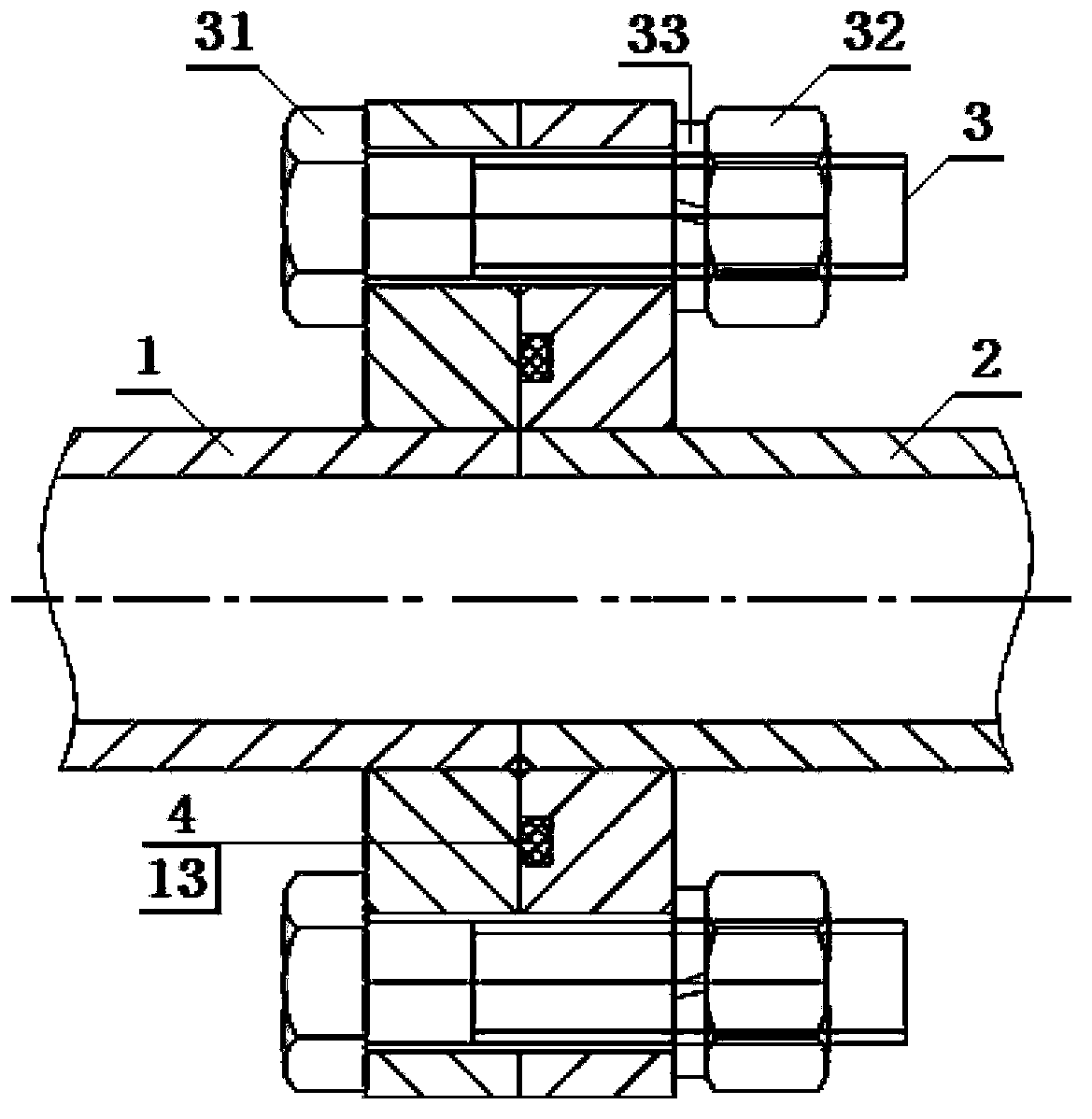

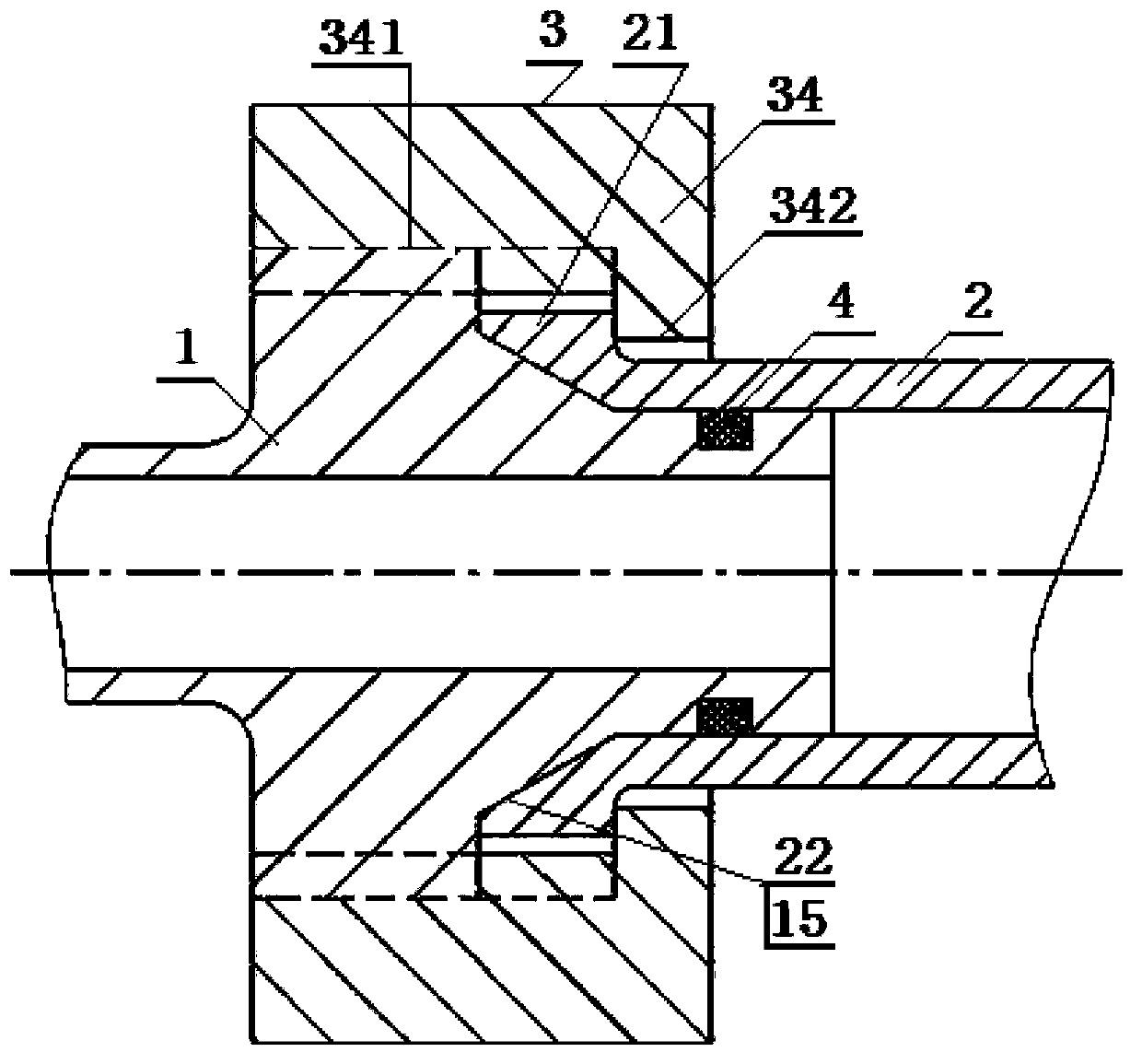

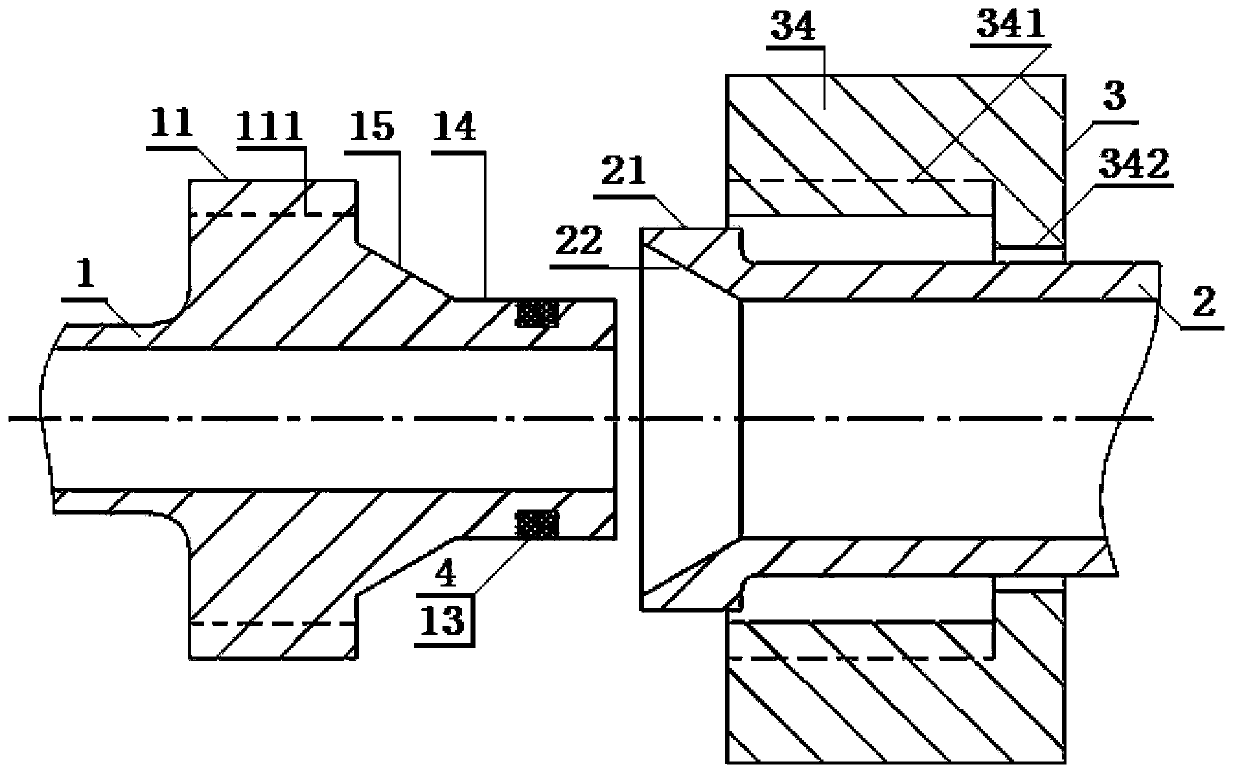

[0022] exist figure 1 , figure 2 and image 3 Among them, the current commonly used water-cooled cable connection devices in industry related to the present invention mainly include flat flange type and bell mouth thread type, wherein: the structure and interconnection method of the flat flange type water-cooled cable connection device are as follows: figure 1 As shown, the main body is composed of the cable joint 1 at the water inlet end, the cable joint 2 at the water outlet end, the fixed assembly member 3 and the sealing ring 4, and the cable joint 1 at the water inlet end and the cable joint 2 at the water outlet end are respectively provided with upper belt interconnection assembly holes and the flange of the sealing ring 4 placement groove, the fixed assembly member 3 includes fastening bolts 31, fastening nuts 32 and spring washers 33...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com