Technology for extracting flavone of peanut shells

A technology of shell flavonoids and peanut shells, which is applied in the application, animal feed, animal feed and other directions, can solve the problems of difficult filtration of the extract, poor extraction effect, low extraction rate, etc., and achieves low cost of raw materials, simple operation, and low extraction rate. rate increase effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] A technique for extracting peanut shell flavonoids, comprising the steps of:

[0019] Dry the peanut shells in a constant temperature drying oven at 70°C, then crush them with a pulverizer, and pass through a 40-mesh sieve;

[0020] Weigh 1000g of peanut shell powder into a container, add 1g of cellulase, the enzyme activity is 20000U / g, then add 1000g of purified water, stir evenly, the reaction time is 10min, and the temperature is 36°C;

[0021] Add 2000g of the first extraction solution, the pH of the first extraction solution is 3.0, stir evenly, control the temperature during the extraction process to 60°C, the microwave power is 500W, and the extraction time is 3min; the first extraction solution is hydrochloric acid solution;

[0022] Collect the filtrate A and precipitate A by suction filtration, add 1000g of the second extract to the precipitate, the pH of the second extract is 7.5, stir evenly, control the temperature at 60°C during the extraction process, an...

Embodiment 2

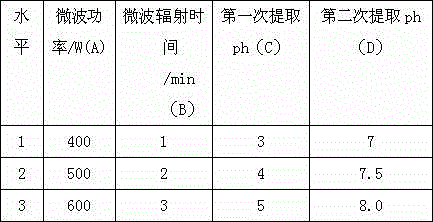

[0027] Orthogonal design

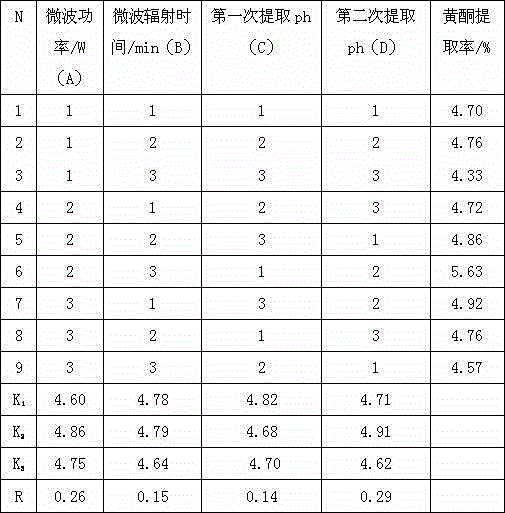

[0028] According to the single factor results, the main extraction factors affecting the extraction of peanut shell flavonoids were microwave power (A), microwave radiation time (min) (B), the first extraction ph (C), and the second extraction ph (D). design. Choose 4 3 Orthogonal experiments were designed to optimize the extraction process of flavonoids in peanut shells and screen out the best extraction conditions. Table 1 is the factor level table; Table 2 is the results and analysis of the orthogonal test.

[0029] Table 1

[0030]

[0031] Table 2

[0032]

[0033] According to the result of orthogonal test: the best combination is A 2 B 3 C 1 D. 2 , that is, at an extraction temperature of 60°C, a microwave power of 500W, the first extraction solution pH 3.0, microwave radiation time of 3 minutes, the second extraction solution pH 7.5, microwave radiation time of 3 minutes, at this time, peanut shells The extraction rate of ...

Embodiment 3

[0035] The bacteriostasis test of peanut shell flavonoids prepared by the present invention on bacteria and fungi, see Table 3

[0036] Flavonoid concentration % E. coli % Bacillus subtilis% Staphylococcus aureus % 0.2 21.33±1.26 29.31±2.49 58.29±1.26 0.26 60.94±1.43 45.62±2.95 74.86±1.72 0.38 100 82.97±2.12 92.54±1.65

[0037] It can be seen from Table 3 that the bacteriostatic rate of different concentrations of peanut shell flavonoids on bacteria was detected. Peanut shell flavonoids had a significant inhibitory effect on the tested bacteria, and with the increase of its concentration, the bacteriostatic rate increased significantly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com