A kind of bismuth oxyhalide photocatalyst and preparation method thereof

A photocatalyst, bismuth oxyhalide technology, applied in chemical instruments and methods, inorganic chemistry, bismuth compounds, etc., can solve problems such as secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

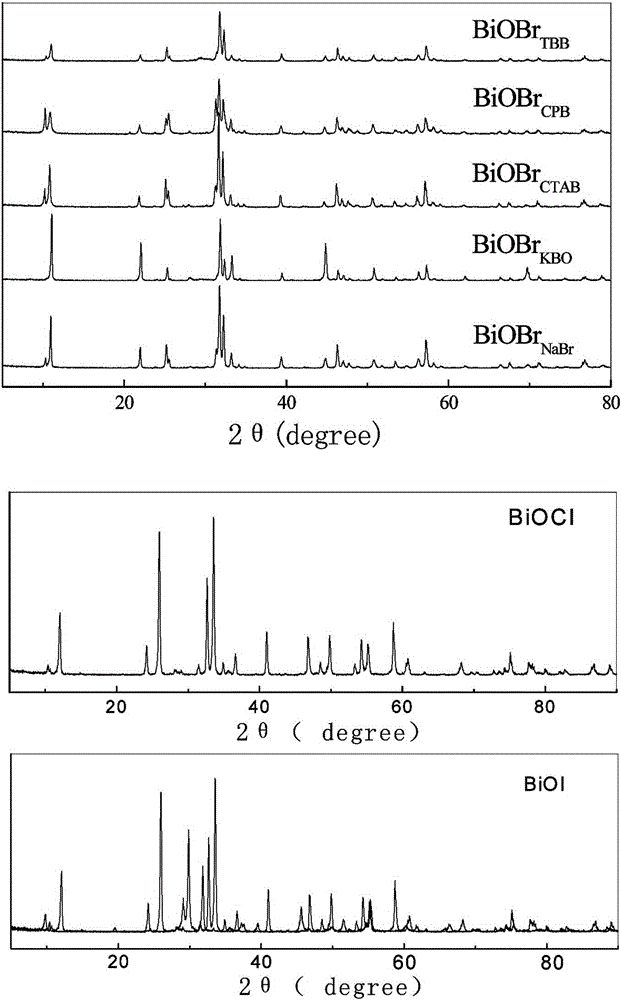

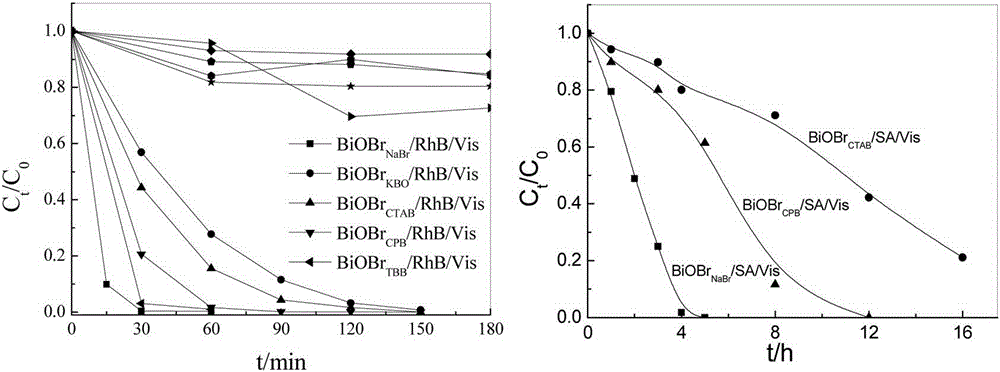

Embodiment 1

[0017] Dissolve 0.001 mol of sodium bromide in 70 mL of deionized water, and add 0.001 mol of sodium bismuthate. Adjust pH=1.16. Place in a 100mL polytetrafluoroethylene reactor and react at 180°C for 24h. After the reaction is complete, filter the resulting precipitate with suction, wash with alcohol and water respectively, and dry at 60°C for 4h.

Embodiment 2

[0019] Dissolve 0.001 mol of cetylpyridine bromide in 70 mL of deionized water, and add 0.001 mol of sodium bismuthate. Adjust pH=1.06. Place in a 100mL polytetrafluoroethylene reactor and react at 180°C for 12h. After the reaction, filter the resulting precipitate with suction, wash with alcohol and water respectively, and dry at 60°C for 4h.

Embodiment 3

[0021] Take 0.001 mol of cetyltrimethylammonium bromide and dissolve it in 70 mL of deionized water, ultrasonically dissolve it, and add 0.001 mol of sodium bismuthate. Adjust pH=1.26. Place in a 100mL polytetrafluoroethylene reactor and react at 160°C for 12h. After the reaction, filter the resulting precipitate with suction, wash with alcohol and water respectively, and dry at 60°C for 4h.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com