Combined tunnel type guide limiting structure of die-casting mold

A die-casting mold and tunnel-type technology, which is applied in the field of combined tunnel-type guiding and limiting structures, achieves the effects of stable final size, improved production qualification rate, and improved service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

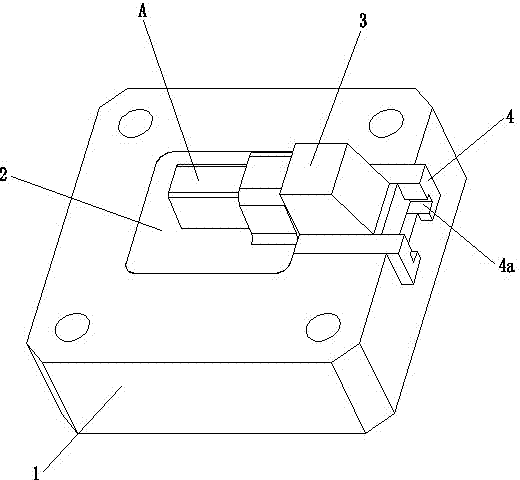

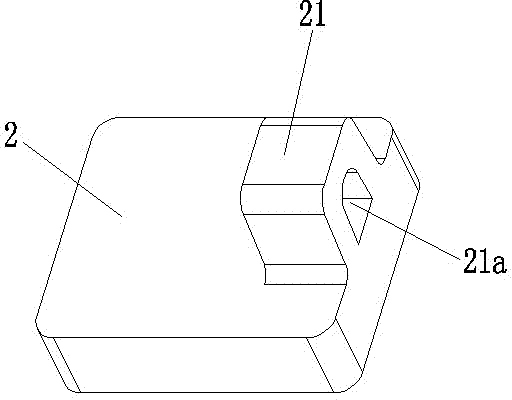

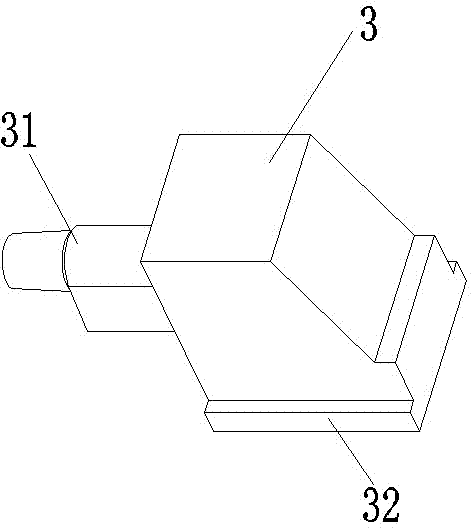

[0021] Figure 1 to Figure 4 It is a structural schematic diagram of the present invention.

[0022] The reference signs are: product part A, part hole K, movable mold frame 1, movable mold cavity 2, tunnel limit block 21, cavity tunnel 21a, core mold slider 3, slider core 31, guide rail convex Side 32, slider guide rail 4, guide rail groove 4a.

[0023] Such as Figure 1 to Figure 4 As shown, a combined tunnel-type guiding and limiting structure of a die-casting mold according to the present invention includes a movable mold frame 1 with a cavity positioning cavity in the center of the upper end surface, a movable mold cavity 2 and a core mold that match the die-casting product part A Slide block 3, the front end of mandrel mold slide block 3 is shaped on the slide block core 31 that is used for the part hole K of molding product part A.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com