Clamp for automatically inlaying cylindrical insert in mold

A technology for cylindrical inserts and molds, which is applied in the field of fixtures for automatically inserting cylindrical inserts in molds. It can solve problems such as accelerating mold wear, reducing mold service life, and operating errors, achieving accurate positioning and improving production efficiency. , Eliminate the effect of operational errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

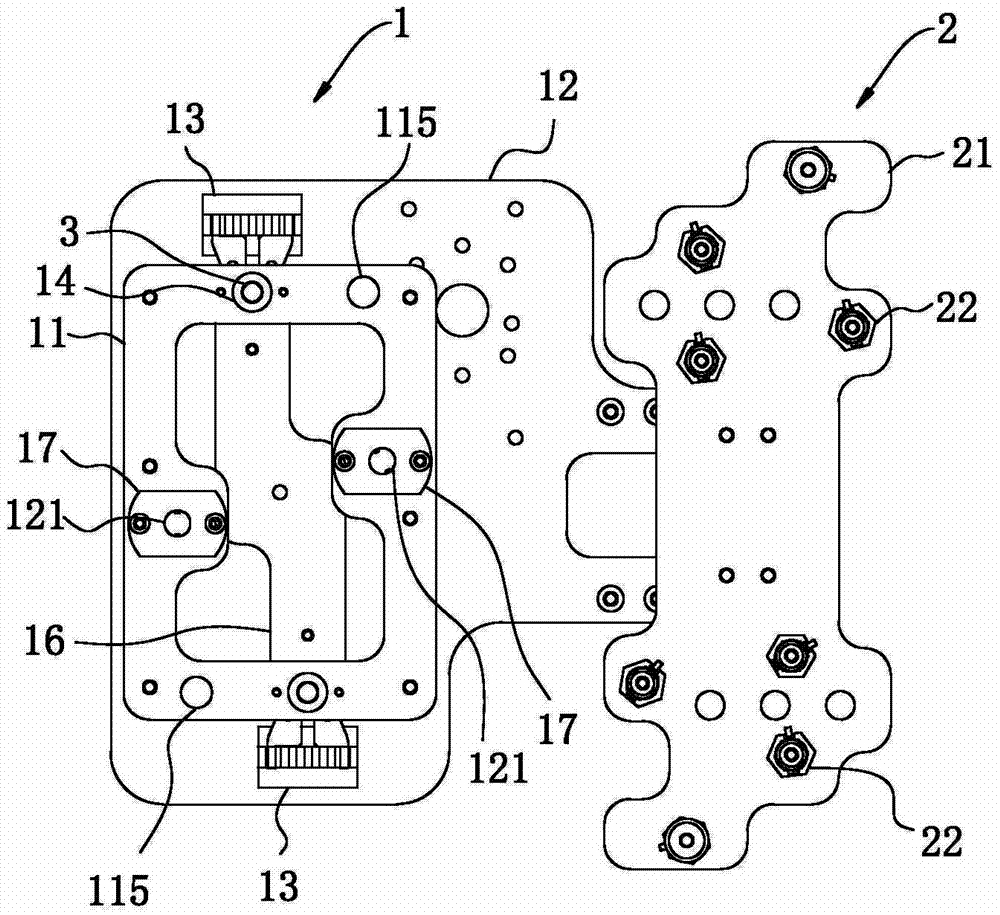

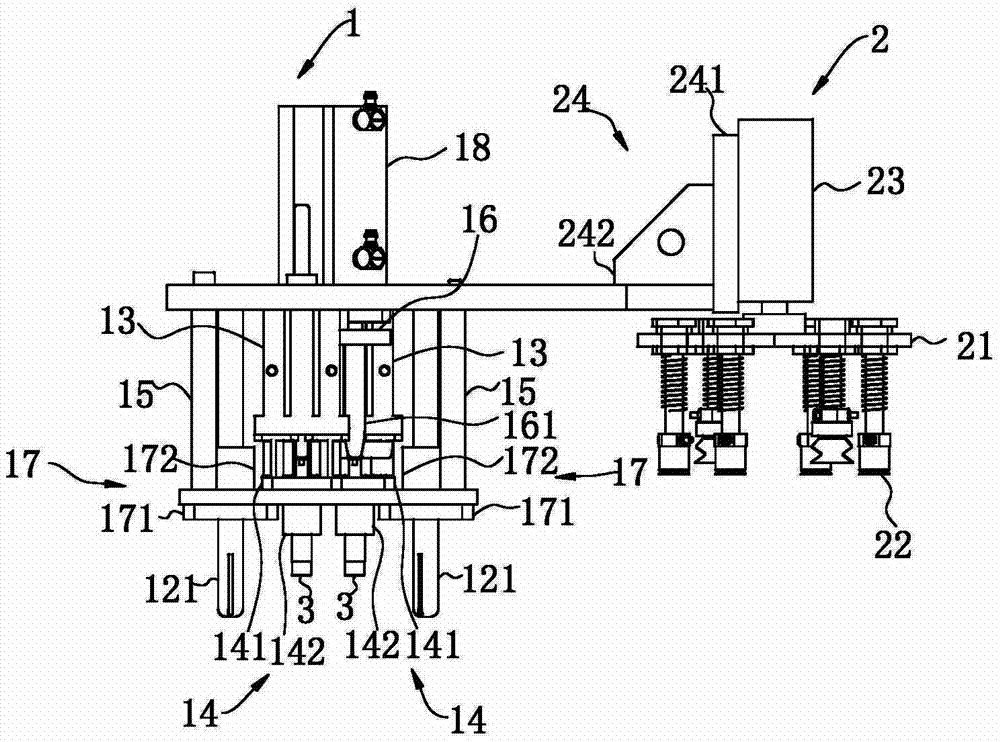

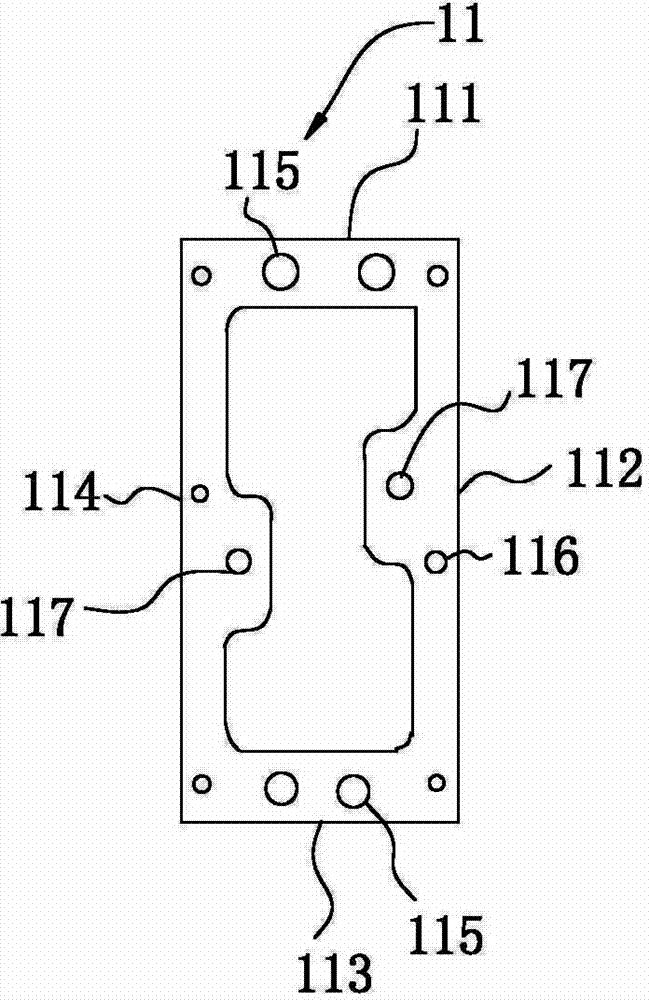

[0032] Such as Figure 1 to Figure 3 As shown, a fixture for automatically inserting a cylindrical insert 3 in a mold according to the present invention includes a clamping installation device 1 and an adsorption device 2. The clamping installation device 1 includes a front fixing plate 11 parallel to the front fixing plate 11. The rear fixed plate 12, the connection and positioning device for connecting the front fixed plate 11 and the rear fixed plate 12, the clamping device 13 and the thrust device, the front fixed plate 11 includes a first end 111, a second end adjacent to the first end 111 Two ends 112, a third end 113 opposite to the first end 111, and a fourth end 114 opposite to the second end 112, the first end 111 and the third end 113 are provided with a positioning hole 115 formed by one-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com